Laser thinning method and laser machine

A laser thinning and laser machine technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as uneven surface, and achieve the effect of high flatness and consistent cutting volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

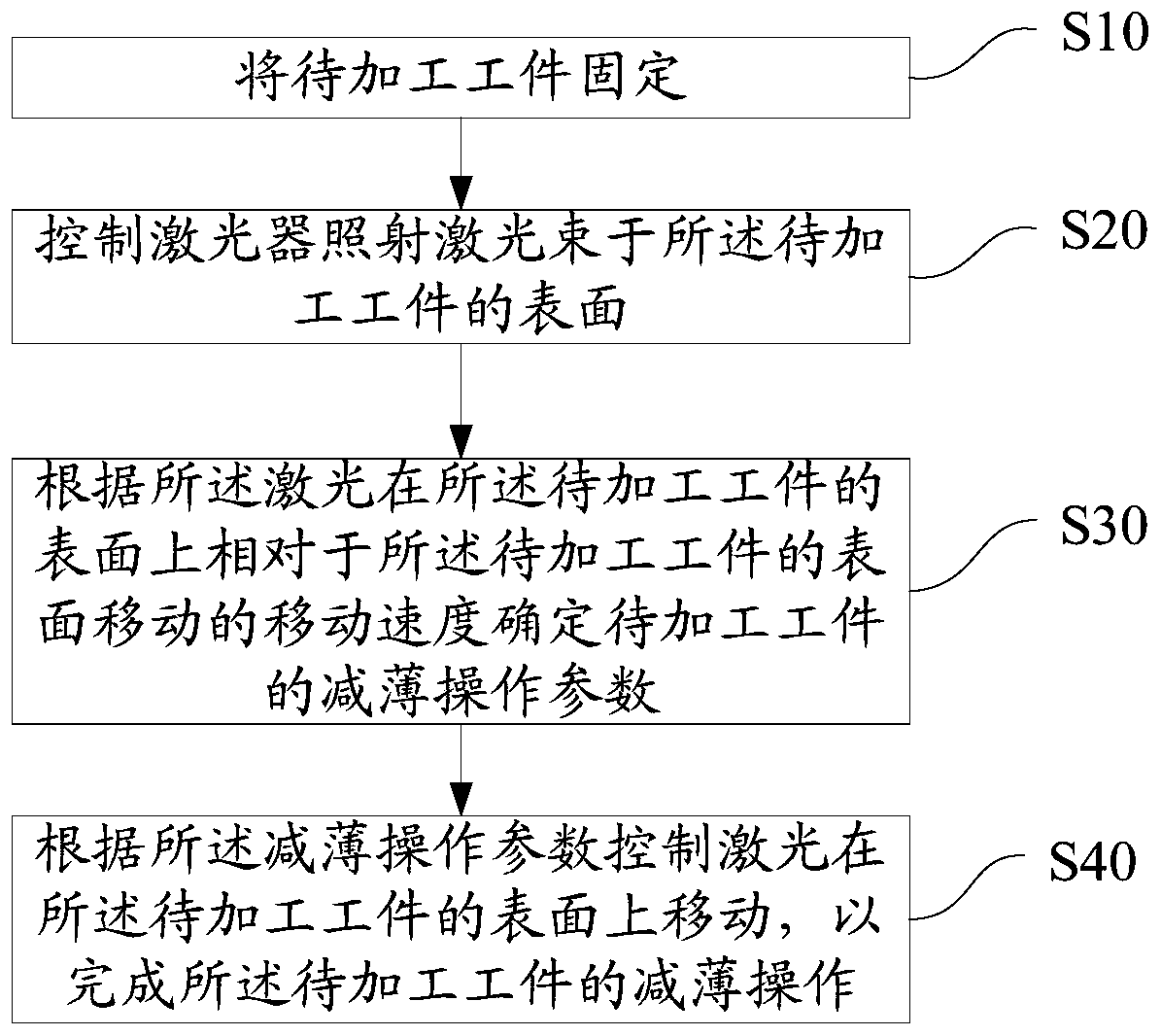

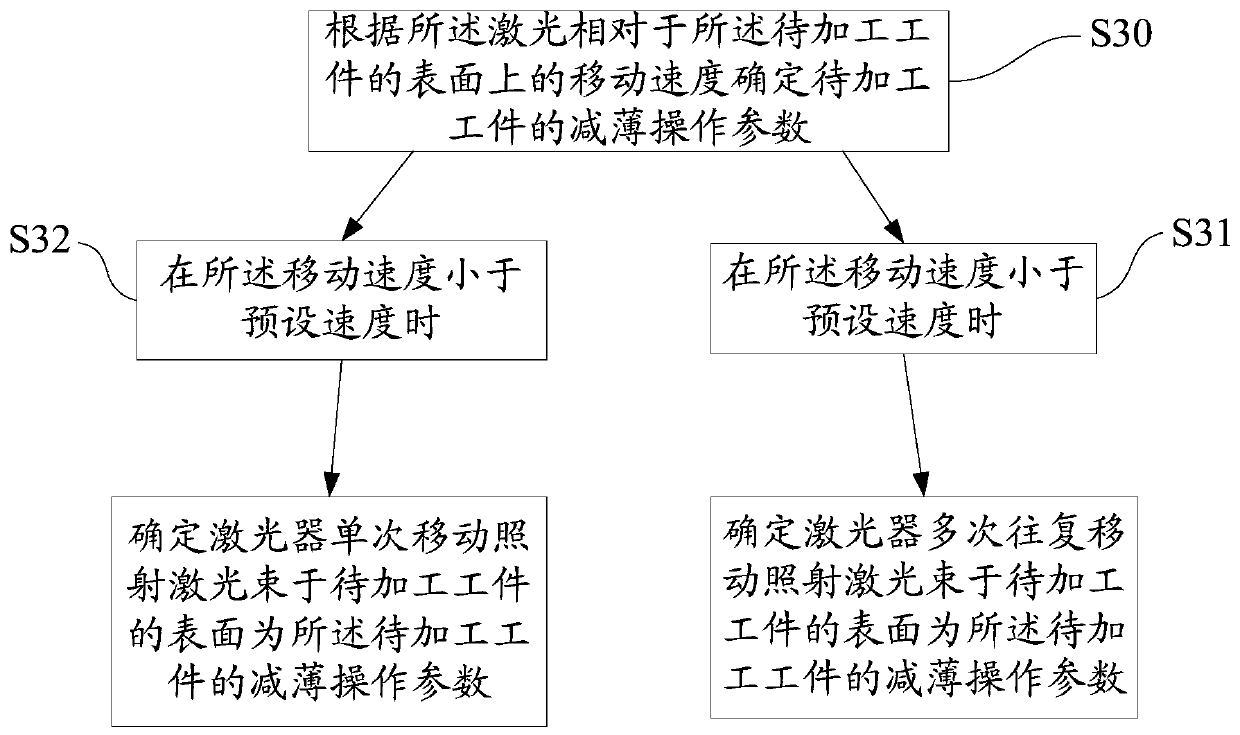

[0079] refer to figure 2 , figure 2 As the first embodiment of the laser thinning method of the present invention, the laser thinning method includes the following steps:

[0080] Step S10, fixing the workpiece to be processed.

[0081] In the present invention, a laser cutting machine refers to a laser cutting machine with a rotating table, and the laser cutting machine is equipped with a rotating table for clamping a workpiece to be processed and driving it to rotate. When the laser machine is running, the laser machine clamps the workpiece to be processed on the rotating table through the built-in fixture so that the workpiece to be processed is fixed for thinning, and the required clamping can be provided according to the weight of the workpiece to be processed force.

[0082] Step S20, controlling the laser to irradiate the surface of the workpiece to be processed.

[0083] Specifically, according to the thickness of the workpiece to be processed, the distance betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com