Porous indium phosphide barrier layer, corrosion liquid of porous indium phosphide and use method

A technology of indium phosphide and barrier layer, which is applied to the field of thinning porous indium phosphide corrosion solution, thinning of porous indium phosphide, and removal of barrier layer on the surface of porous indium phosphide, which can solve the problem of poor quality, porous layer falling off, Removal and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A porous indium phosphide barrier layer and an etching solution for porous indium phosphide according to the present invention are characterized in that they include:

[0034] The mixed solution of hydrobromic acid, nitric acid and water, the weight portion of this mixed solution is:

[0035] Hydrobromic acid: 1-2;

[0036] Nitric acid: 1-2;

[0037] Water: 10-20.

[0038] A method for preparing a porous indium phosphide barrier layer and a porous indium phosphide corrosion solution according to the present invention is characterized in that it comprises:

[0039] The mixed solution of hydrobromic acid, nitric acid and water, the weight portion of this mixed solution is:

[0040] Hydrobromic acid: 1-2;

[0041] Nitric acid: 1-2;

[0042] Water: 10-20;

[0043] Mix hydrobromic acid, nitric acid, and water and stir.

[0044] Wherein the mixed solution can be used after being stored for more than one month, so as to ensure the uniformity of the mixed solution.

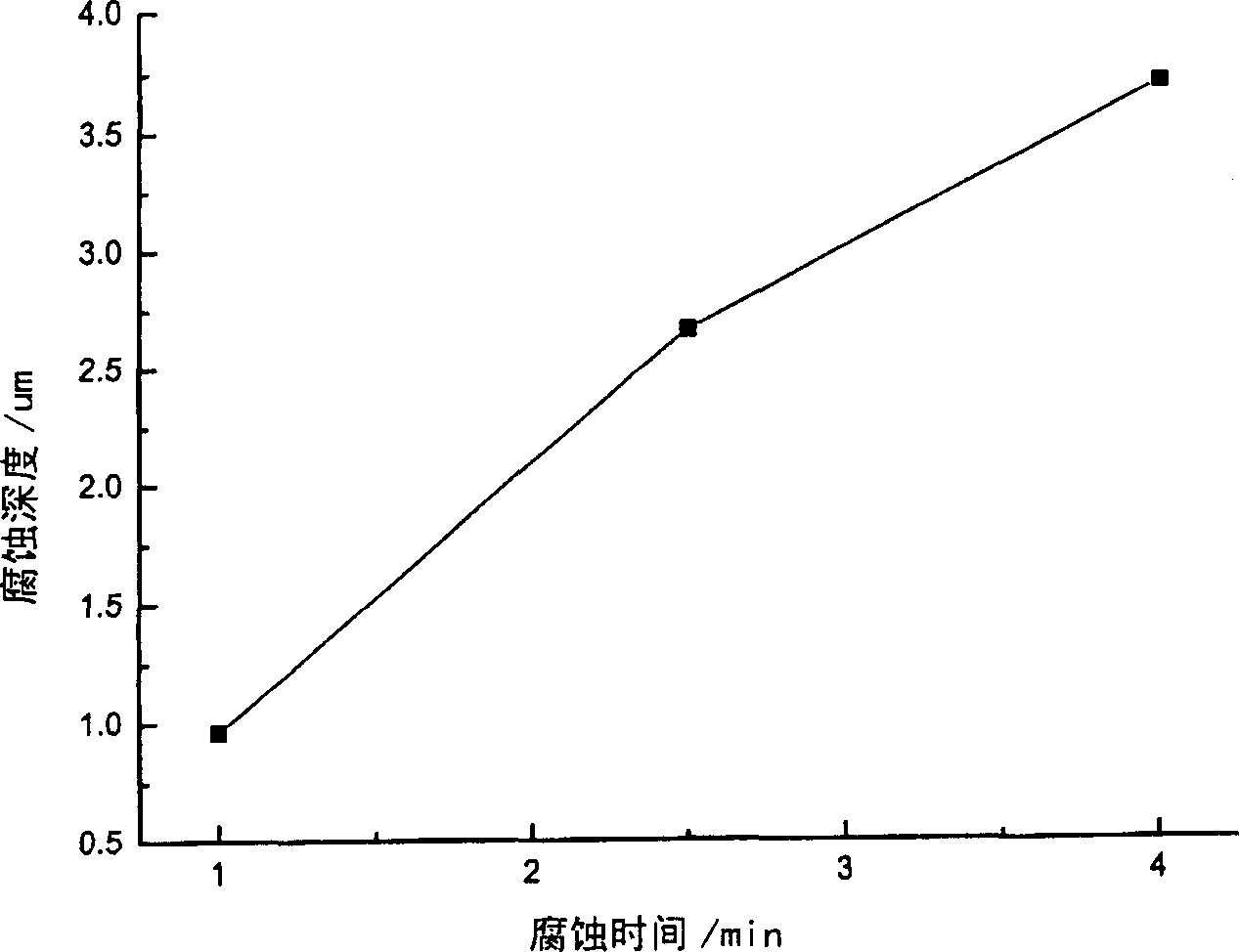

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com