A kind of etchant suitable for deposited state gh3536 alloy and its corrosion method

A technology of GH3536 and etchant, which is applied in the field of metallographic corrosion, can solve the problems of long corrosion time, high corrosion difficulty, and affecting corrosion efficiency, and achieve the effect of high-efficiency corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

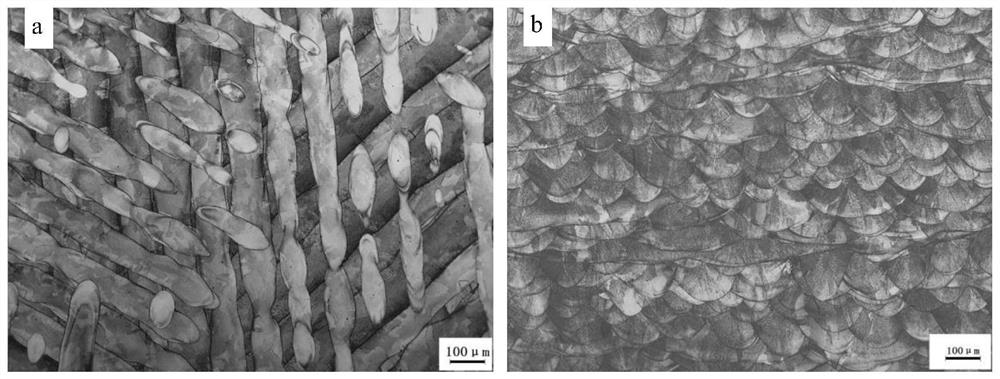

[0036] The sample is the deposited GH3536 alloy prepared by SLM. Grinding and polishing are carried out by conventional methods before etching.

[0037] The formula of the corrosive agent is 50ml of distilled water: 180ml of analytical pure hydrochloric acid: 15g of chromium oxide.

[0038] The corrosive agent configuration steps include: accurately weigh the chromium oxide with a balance, pour the solid chromium oxide into the plastic reagent storage bottle, then accurately weigh the quantitative distilled water with the measuring cylinder and pour it into the plastic reagent storage bottle, and then use the measuring cylinder in the fume hood to accurately Weigh the quantitative hydrochloric acid, and slowly pour it into the plastic reagent storage bottle, and finally shake the mixed solution in the plastic reagent storage bottle to ensure that the chromium oxide is dissolved as much as possible (in the actual process, there will be residual solids in the chromium oxide), an...

Embodiment 2

[0042] The sample is the deposited GH3536 alloy prepared by SLM. Grinding and polishing are carried out by conventional methods before etching.

[0043] The corrosive agent formula is 60ml of distilled water: 150ml of analytical pure hydrochloric acid: 15g of chromium oxide.

[0044] The corrosive agent configuration steps include: accurately weigh the chromium oxide with a balance, pour the solid chromium oxide into the plastic reagent storage bottle, then accurately weigh the quantitative distilled water with the measuring cylinder and pour it into the plastic reagent storage bottle, and then use the measuring cylinder in the fume hood to accurately Weigh the quantitative hydrochloric acid, and slowly pour it into the plastic reagent storage bottle, and finally shake the mixed solution in the plastic reagent storage bottle to ensure that the chromium oxide is dissolved as much as possible (in the actual process, there will be residual solids in the chromium oxide), and place...

Embodiment 3

[0048] The sample is the deposited GH3536 alloy prepared by SLM. Grinding and polishing are carried out by conventional methods before etching.

[0049] The formula of the corrosive agent is 70ml of distilled water: 180ml of analytical pure hydrochloric acid: 20g of chromium oxide.

[0050] The corrosive agent configuration steps include: accurately weigh the chromium oxide with a balance, pour the solid chromium oxide into the plastic reagent storage bottle, then accurately weigh the quantitative distilled water with the measuring cylinder and pour it into the plastic reagent storage bottle, and then use the measuring cylinder in the fume hood to accurately Weigh the quantitative hydrochloric acid, and slowly pour it into the plastic reagent storage bottle, and finally shake the mixed solution in the plastic reagent storage bottle to ensure that the chromium oxide is dissolved as much as possible (in the actual process, there will be residual solids in the chromium oxide), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com