A kind of silicon etching liquid and its production process

A technology of corrosive solution and mixed solution, applied in the direction of final product manufacturing, surface etching composition, sustainable manufacturing/processing, etc., can solve problems such as unqualified, metal wire corrosion, defective substrate, etc., and achieve good film formation , the effect of increasing fluidity and increasing water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

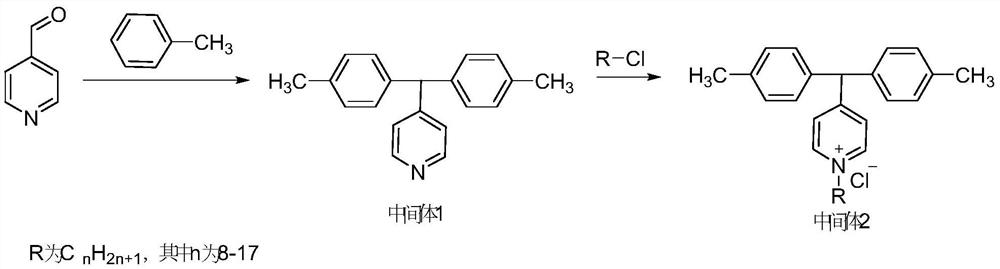

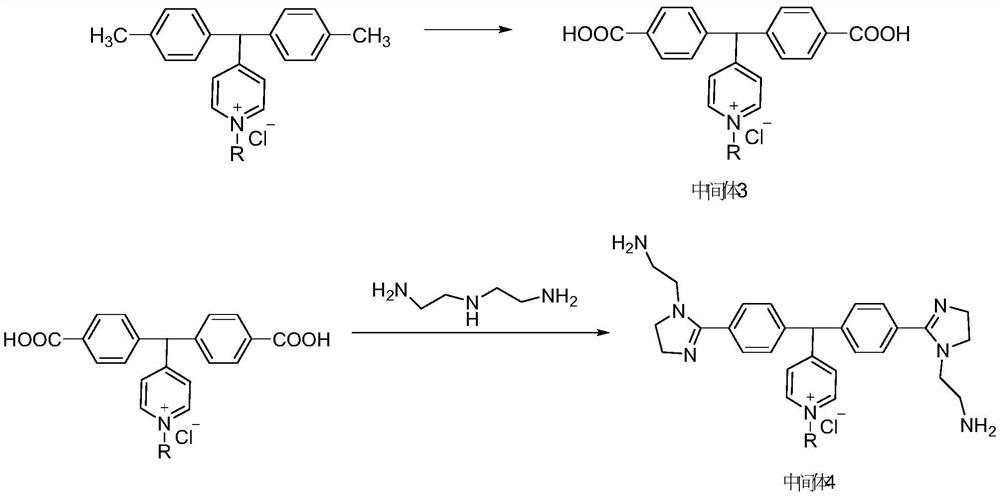

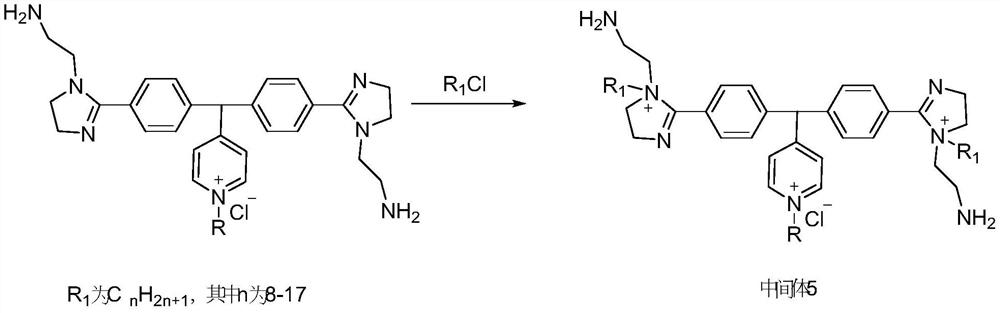

[0022] Composite corrosion inhibitors are made through the following steps:

[0023] Step A, add pyridine-4-carbaldehyde, toluene and glacial acetic acid into a three-necked flask in turn, stir evenly, cool to 0°C, slowly add a mixed solution of concentrated sulfuric acid and glacial acetic acid dropwise while stirring, the dropping speed is 1 drop / Seconds, after the addition is complete, continue to react at 0°C and 200r / min for 36h, then pour into ice water, stir for 50min, filter, take the filter cake and wash and filter repeatedly with ice water until the filtrate is neutral, then filter The cake was vacuum-dried to constant weight to obtain intermediate 1; after heating and melting intermediate 1, chlorinated hydrocarbon A was slowly added dropwise with a constant pressure dropping funnel, the reaction system was heated to 100°C, and reacted at constant temperature for 4 hours to obtain intermediate 2 , the reaction is shown below, wherein the ratio of the mixed solution...

Embodiment 2

[0027] Composite sustained-release preparations are made through the following steps:

[0028]Step A, add pyridine-4-carbaldehyde, toluene and glacial acetic acid into a three-necked flask in turn, stir evenly, cool to 0°C, slowly add a mixed solution of concentrated sulfuric acid and glacial acetic acid dropwise while stirring, the dropping speed is 1 drop / Seconds, after the addition is complete, continue to react at 0°C and 300r / min for 36h, then pour into ice water, stir for 50min, filter, take the filter cake and wash and filter repeatedly with ice water until the filtrate is neutral, then filter The cake was vacuum-dried to constant weight to obtain intermediate 1; after heating and melting intermediate 1, chlorinated hydrocarbon A was slowly added dropwise with a constant pressure dropping funnel, the reaction system was heated to 100°C, and reacted at constant temperature for 4 hours to obtain intermediate 2 , the reaction is shown below, wherein the ratio of the mixed...

Embodiment 3

[0032] A silicon corrosion solution, including the following raw materials in parts by weight: 8 parts of hydrofluoric acid, 70 parts of nitric acid, 15 parts of deionized water, 6 parts of composite corrosion inhibitor, and the composite sustained release agent is prepared in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com