Method and device for removing phosphine in tail gas of yellow phosphorus boiler through oxidation

A yellow phosphorus furnace and tail gas technology, which is applied in the field of phosphine removal in the yellow phosphorus furnace tail gas, can solve the problems of difficult use of catalysts, decreased dephosphine efficiency, and increased cost, achieving efficient dephosphine removal, reduced corrosion, and extended use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] PH in the tail gas of yellow phosphorus furnace 3 The removal method, the process steps are: lead the tail gas of the yellow phosphorus furnace into the dust removal and phosphorus removal tank, use the liquid in the dust removal and phosphorus removal tank to remove a small amount of elemental yellow phosphorus and phosphorus pentoxide in the tail gas of the yellow phosphorus furnace; The tail gas of the yellow phosphorus furnace after phosphorus is passed into the alkali absorption tower, and the SO in the tail gas of the yellow phosphorus furnace is removed by a desulfurizer 2 , HF and other acid gases; finally, the yellow phosphorus furnace tail gas treated by the alkali absorption tower is passed into the dephosphine tower, and sprayed by the dephosphine agent in the dephosphine tower, the liquid in the dust removal and phosphorus removal tank is water, and the desulfurizer 20%wt Na 2 CO 3 , the dephosphine agent is 10%wt potassium permanganate solution.

Embodiment 2

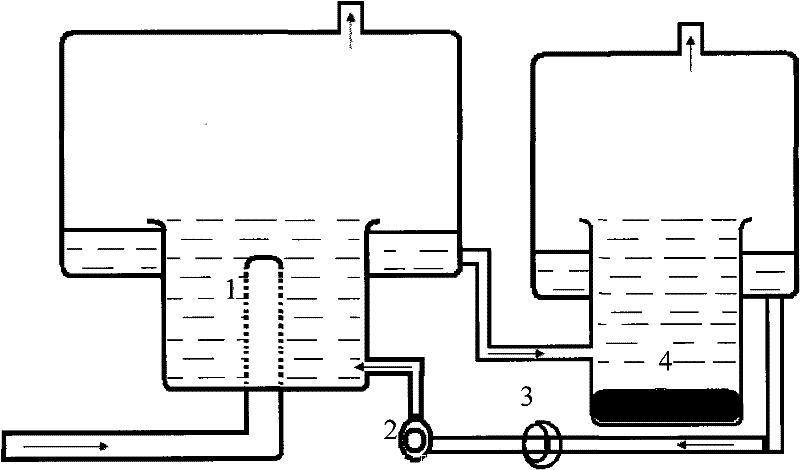

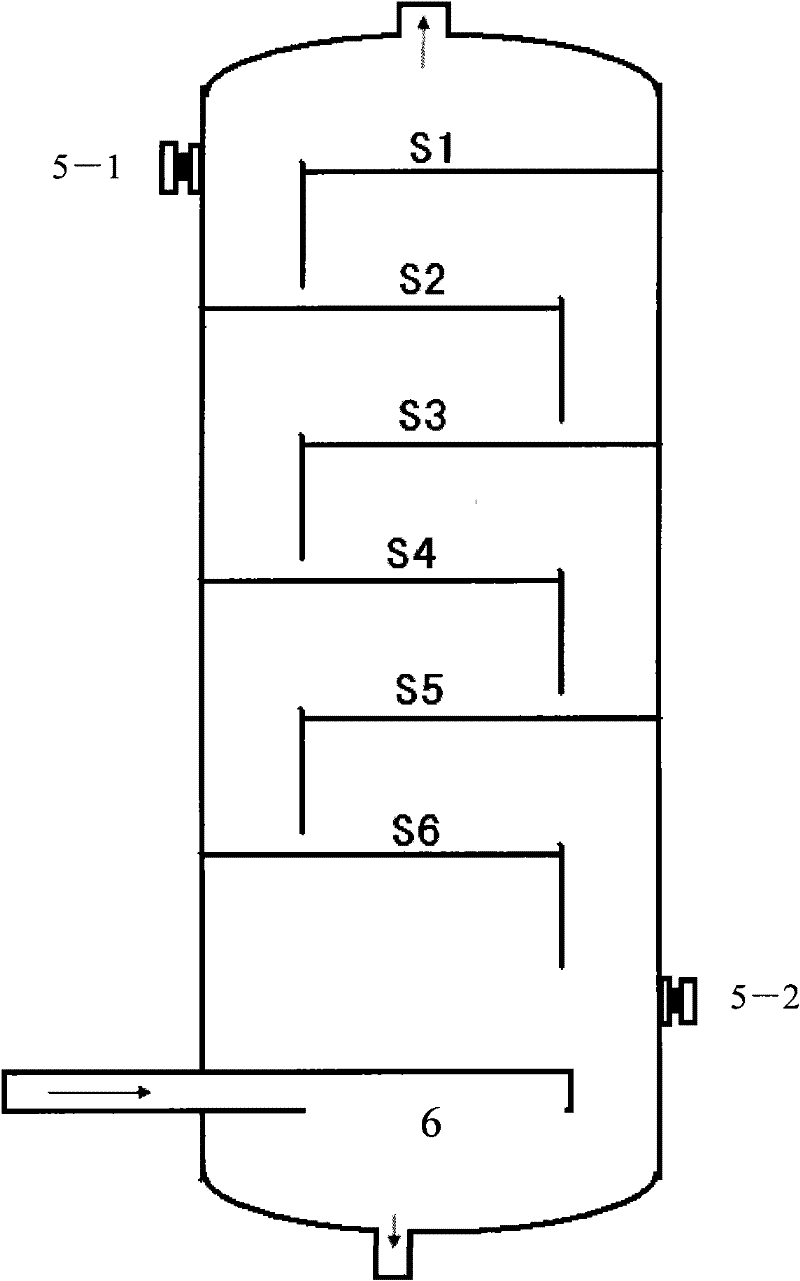

[0021] Removal of PH in tail gas of yellow phosphorus furnace 3 The device includes a dust removal and phosphorus removal tank, an alkali absorption tower and a dephosphorization tower. The dust removal and phosphorus removal tank contains a dust removal and phosphorus removal liquid, and a gas distribution pipe is arranged under the liquid surface, and the tail gas of the yellow phosphorus furnace enters the dust removal and phosphorus removal tank through the gas distribution pipe , the top of the dedusting and phosphorus removal tank is provided with a tail gas outlet, and the tail gas outlet is connected with the tail gas inlet at the bottom of the alkali absorption tower through a gas guide pipe, and the top of the alkali absorption tower is provided with a desulfurizer spray device and a tail gas outlet, and the alkali absorption tower The tail gas outlet is connected to the tail gas inlet at the bottom of the dephosphination tower, and the top of the dephosphination towe...

Embodiment 3

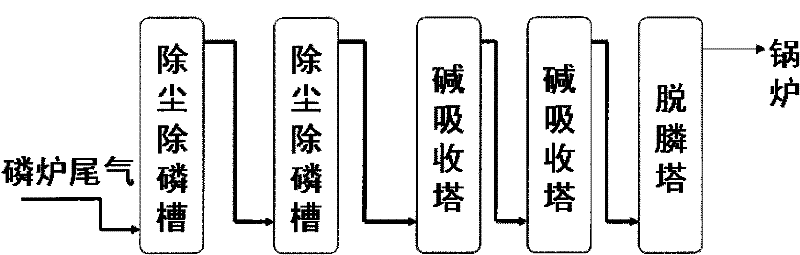

[0023] The wet oxidative dephosphination process system consists of dust removal and phosphorus removal tank, alkali absorption tower and dephosphination tower, etc., such as figure 1 shown.

[0024] The tail gas of the yellow phosphorus furnace comes in from the main pipe of the yellow phosphorus furnace device, and its pressure is 40-60mbar. The water level of the water seal is adjusted according to the pressure requirements through the water seal tank, and the pressure is adjusted to a slight positive pressure. It enters the dust removal and phosphorus removal tank from the outlet to remove dust and phosphorus. The tank is filled with a certain liquid level to ensure that the gas pipe is submerged in water, and the phosphorus furnace gas bulges out from the evenly distributed small holes. The water in the dust and phosphorus removal tank is supplied by the pump, and the overflow water is collected and recycled by the overflow tank. The sludge phosphorus deposited in the ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com