A kind of graphene catalyzed substrate corrosion solution and substrate corrosion method

A catalytic substrate and graphene technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of destroying the integrity of graphene, graphene pollution, and difficulty in cleaning, so as to achieve good performance and ensure integrity performance, and the effect of increasing the production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A graphene catalyzed substrate corrosion solution, comprising the following components: a phosphoric acid solution with a mass concentration of 5-10%, a glacial acetic acid solution with a mass concentration of 7-12%, and FeCl with a mass concentration of 20-25% 3 Solution, using phosphoric acid solution: glacial acetic acid solution: FeCl 3 Solution=(2-4):(3-6):(5-10) ratio mixing.

[0038] The following examples are the application of the etching solution prepared in Example 1.

Embodiment 2

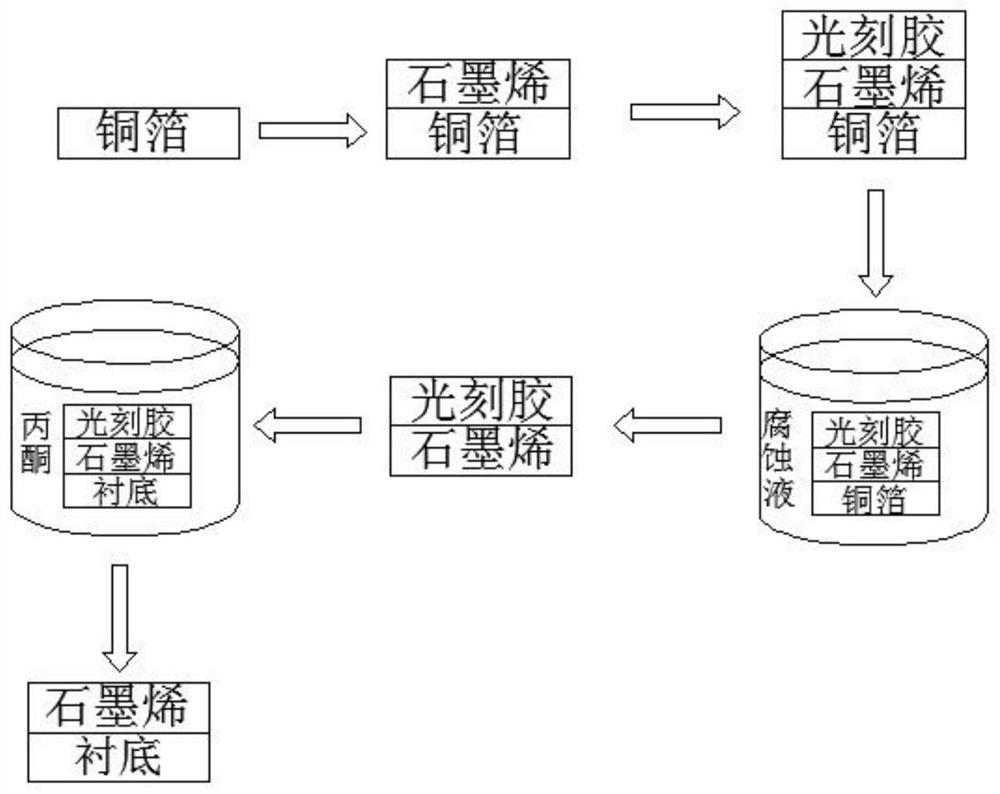

[0040] A kind of graphene catalysis substrate corrosion method, comprises the following steps:

[0041] (1) Utilize CVD method to grow graphene on copper foil substrate, obtain graphene / copper foil substrate;

[0042] (2) Pick up the graphene / copper foil substrate prepared in step (1) with tweezers, place it in the center of the spin coater, suck up an appropriate amount of photoresist with a straw, and drop it on the graphene-growing side of the graphene / copper foil substrate In the center of the top, turn on the spin coater to spin the photoresist. The spin coating process is divided into two stages: the first stage, the spin coater rotates at 400r / s, and rotates for 10s; the second stage, the spin coater rotates at 1500r / s, rotate 25s;

[0043] (3) After the spin coating is completed, use tweezers to pick up the photoresist / graphene / copper foil substrate, place it on a dryer, and dry it at 100°C for 3 minutes to obtain a dried photoresist / graphene / copper foil substrate;

...

Embodiment 3

[0048] A kind of graphene catalysis substrate corrosion method, comprises the following steps:

[0049] (1) Utilize CVD method to grow graphene on copper foil substrate, obtain graphene / copper foil substrate;

[0050] (2) Pick up the graphene / copper foil substrate prepared in step (1) with tweezers, place it in the center of the spin coater, suck up an appropriate amount of photoresist with a straw, and drop it on the graphene-growing side of the graphene / copper foil substrate In the center of the top, turn on the spin coater for photoresist spin coating. The spin coating process is divided into two stages: the first stage, the spin coater rotates at 500r / s, and rotates for 8s; the second stage, the spin coater rotates at 2000r / s, rotate 20s;

[0051] (3) After the spin coating is completed, use tweezers to pick up the photoresist / graphene / copper foil substrate, place it on a dryer, and dry it at 120°C for 2 minutes to obtain a dried photoresist / graphene / copper foil substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com