Repairing paste for slight scratches of optical glass

A technology of optical glass and repair paste, which is applied in the field of repair paste for minor scratches on optical glass. It can solve the problems of complicated grinding and polishing process equipment, affecting the light transmittance of optical glass, and impractical use of optical glass, so as to improve the yield rate of optical products. , Eliminate minor scratches, low repair cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

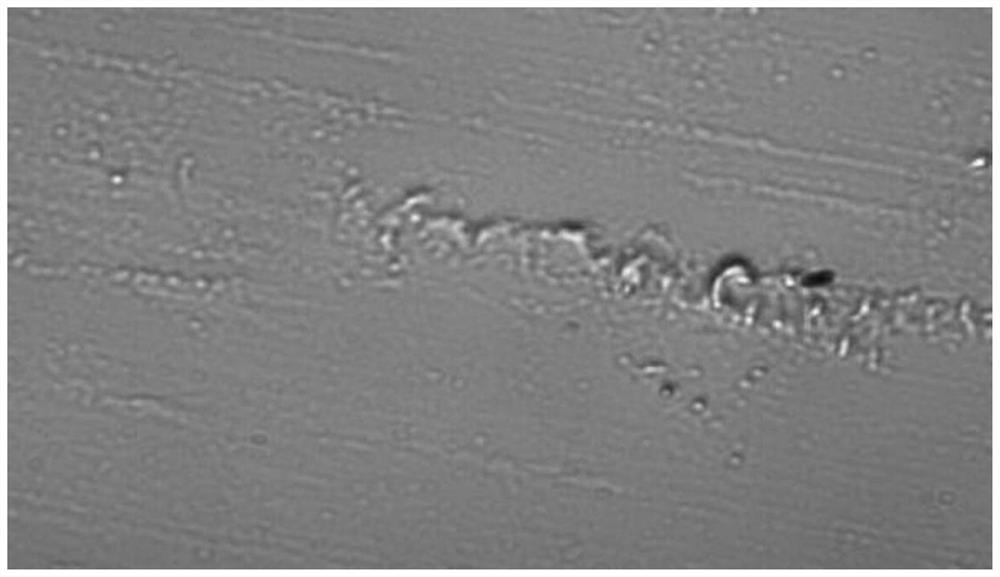

Image

Examples

Embodiment 1

[0029] 1. According to the ratio of 2.5 parts of water, 2 parts of ammonium bifluoride, 0.5 parts of hydrofluoric acid, 1 part of nitric acid, 0.5 parts of phosphoric acid, 1 part of oxalic acid, 2 parts of calcium dihydrogen phosphate, and 0.05 parts of gum, prepare glass slight scratch repair paste;

[0030] 2. Fully stir the prepared scratch repair paste in the PVC container;

[0031] 3. Then pack it into PVC plastic barrels and keep it sealed;

[0032] 4. It can be put into use after being stirred evenly again during use; the repair effect of slight scratches on the glass after use is very good.

Embodiment 2

[0034] 1. According to the ratio of 3 parts of water, 2.5 parts of ammonium bifluoride, 0.5 parts of hydrofluoric acid, 0.5 parts of nitric acid, 0.5 parts of phosphoric acid, 1 part of oxalic acid, 2.5 parts of calcium dihydrogen phosphate, and 0.05 parts of gum, prepare glass slight scratch repair paste;

[0035] 2. Fully stir the prepared scratch repair paste in the PVC container;

[0036] 3. Then pack it into PVC plastic barrels and keep it sealed;

[0037] 4. During the service period, it should be stirred evenly before it can be put into use; after use, the repair effect of slight scratches on the glass is very good.

Embodiment 3

[0039] 1. According to the ratio of 2 parts of water, 2 parts of ammonium bifluoride, 0.5 parts of hydrofluoric acid, 1.5 parts of nitric acid, 0.5 parts of phosphoric acid, 1 part of oxalic acid, 2.5 parts of calcium dihydrogen phosphate, and 0.05 parts of gum, prepare glass slight scratch repair paste;

[0040] 2. Fully stir the prepared scratch repair paste in the PVC container;

[0041] 3. Then pack it into PVC plastic barrels and keep it sealed;

[0042] 4. During the service period, it should be stirred evenly before it can be put into use; after use, the repair effect of slight scratches on the glass is very good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com