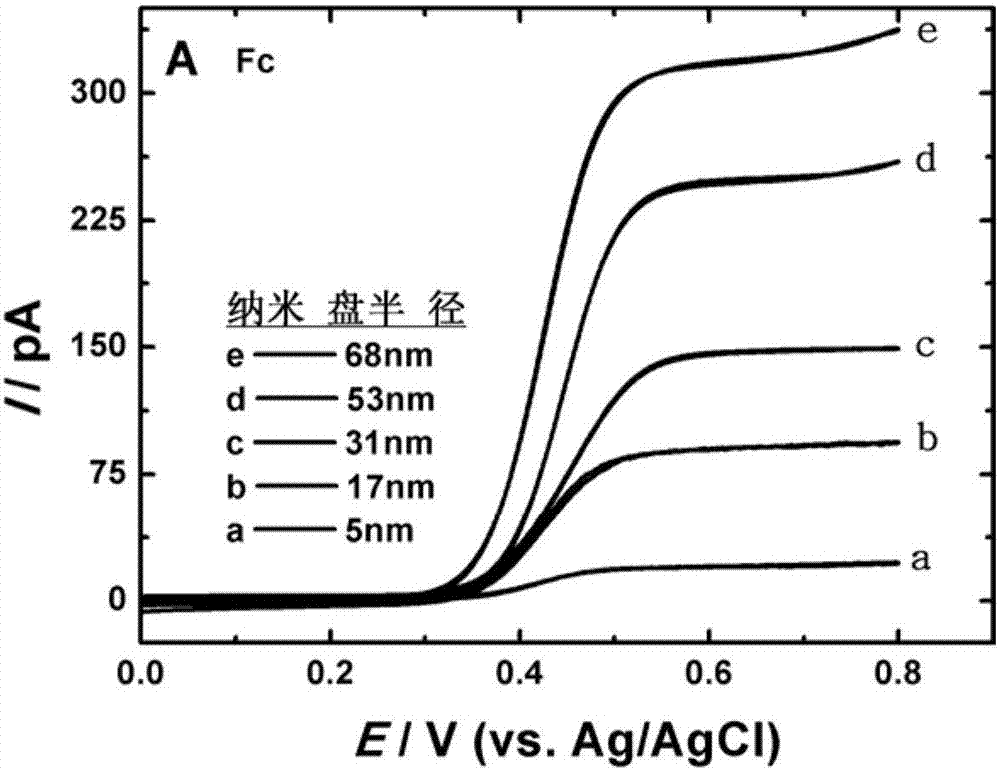

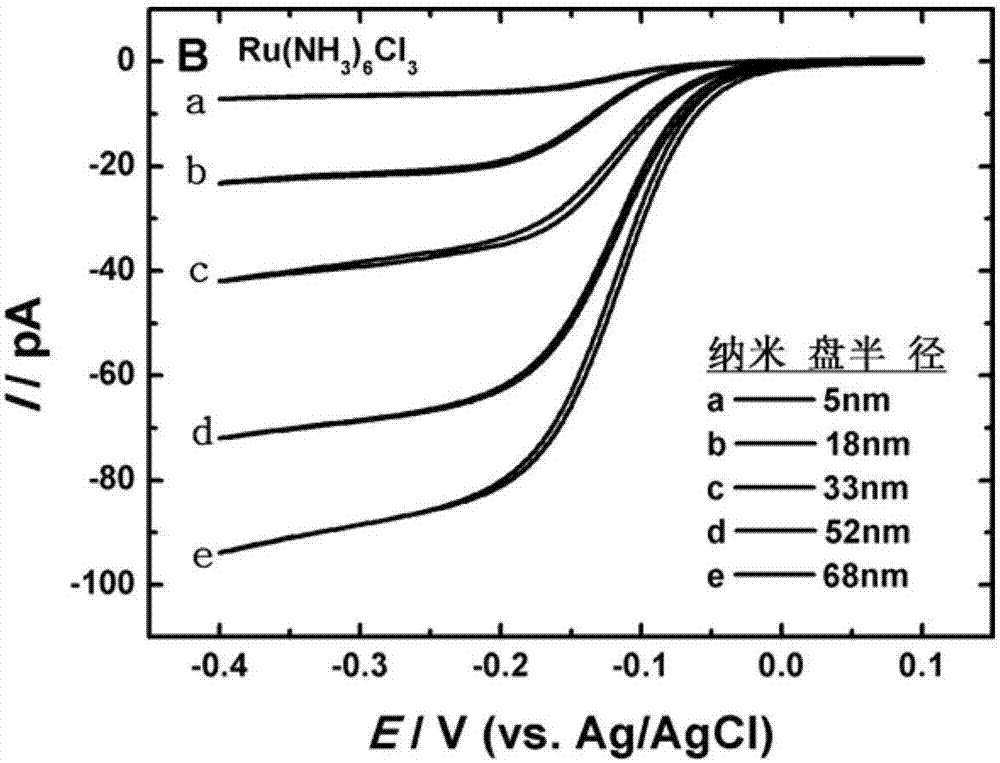

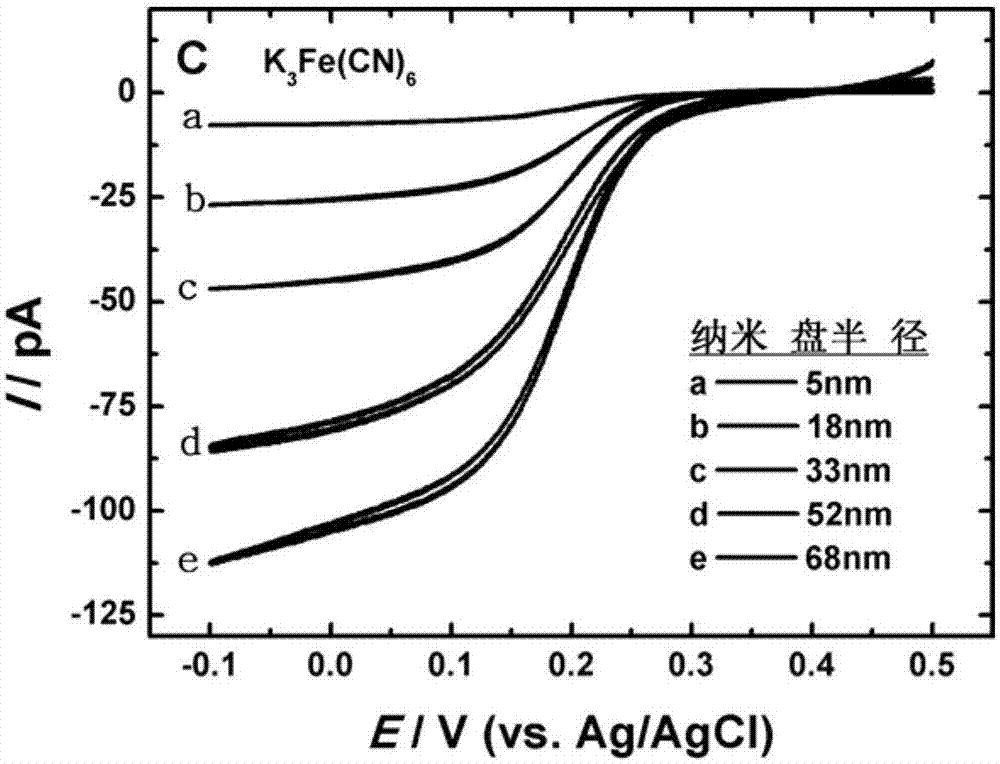

Au@Pt core-shell structure nano electrode, preparing method and application of Au@Pt core-shell structure nano electrode

A nano-electrode, core-shell structure technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of simple method, wide detection range and excellent electrode properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for preparing an Au@Pt core-shell structure nano-electrode, comprising the following steps:

[0058] 1) Preparation of gold nanodisk electrodes:

[0059] a. Encapsulate a gold wire with a diameter of 25 μm and a length of 1-3 cm in a capillary with a length of 7-10 cm, and then draw it with a P-2000 laser drawing machine. In order to prevent the capillary and gold wire from being fused, the determined heating parameters are: The heating temperature is 400-460°C, four heating cycles, each cycle is heated for 15-25s, cooled for 35-45s, and always kept in a vacuum state;

[0060] b. The melted capillary / gold wire, heating temperature 400-460°C, pulling force 130-150N, speed 45-55m / s, the drawn nano-electrodes are observed with an OLYMPUS biological microscope until the tip diameter of the probe is less than 100 nanometers ;

[0061] c. Connect gold wire and tungsten wire (diameter 180 μm) with silver conductive glue as the conductive contact surface, put the dra...

Embodiment 2

[0070] An application of an Au@Pt core-shell structure nano-electrode to catalyze the oxidation-reduction reaction of hydrogen peroxide, and the application of detecting the concentration of hydrogen peroxide by catalyzing the oxidation-reduction reaction of hydrogen peroxide, specifically:

[0071] The Au@Pt core-shell nanoelectrode was placed in 5 mL of 0.1 M PBS (pH=7), and the potential was set to 0.15 V by chronoamperometry, and 50 μL of 40 μM hydrogen peroxide solution was added sequentially (50 μL of 40 μM hydrogen peroxide solution was added in turn). Hydrogen peroxide solution, add 50 μL of 40 μM hydrogen peroxide solution after the current signal is stable), as the hydrogen peroxide concentration increases, the response current increases significantly, and the linear relationship between the hydrogen peroxide concentration and the current signal is constructed; Under the same conditions, the current signal of the hydrogen peroxide solution was detected, and its concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com