Preparation method of 2xxx series aluminum alloy transmission electron microscope sample

A technology for TEM samples and aluminum alloys, which is used in the preparation, sampling, and material analysis using wave/particle radiation. It can solve problems such as poor quality and long sample period, and achieve high thinning rate quality, the effect of eliminating oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

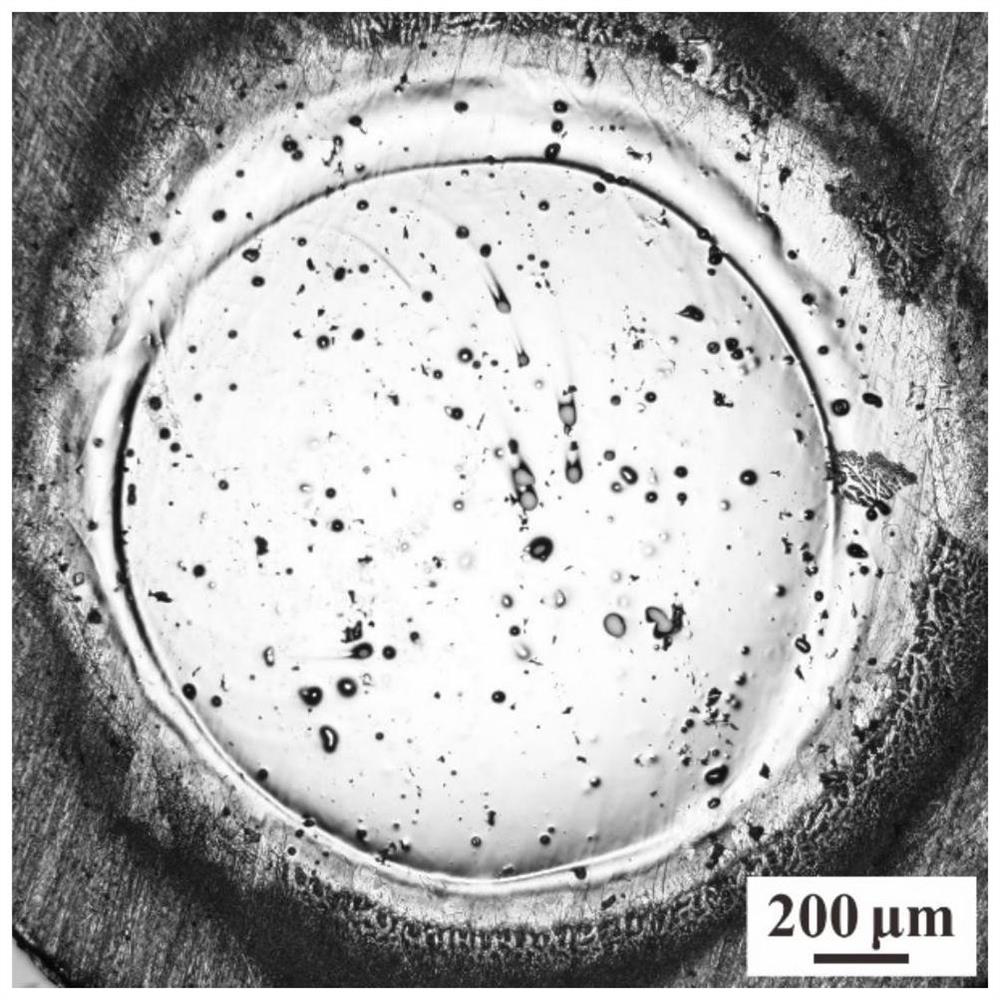

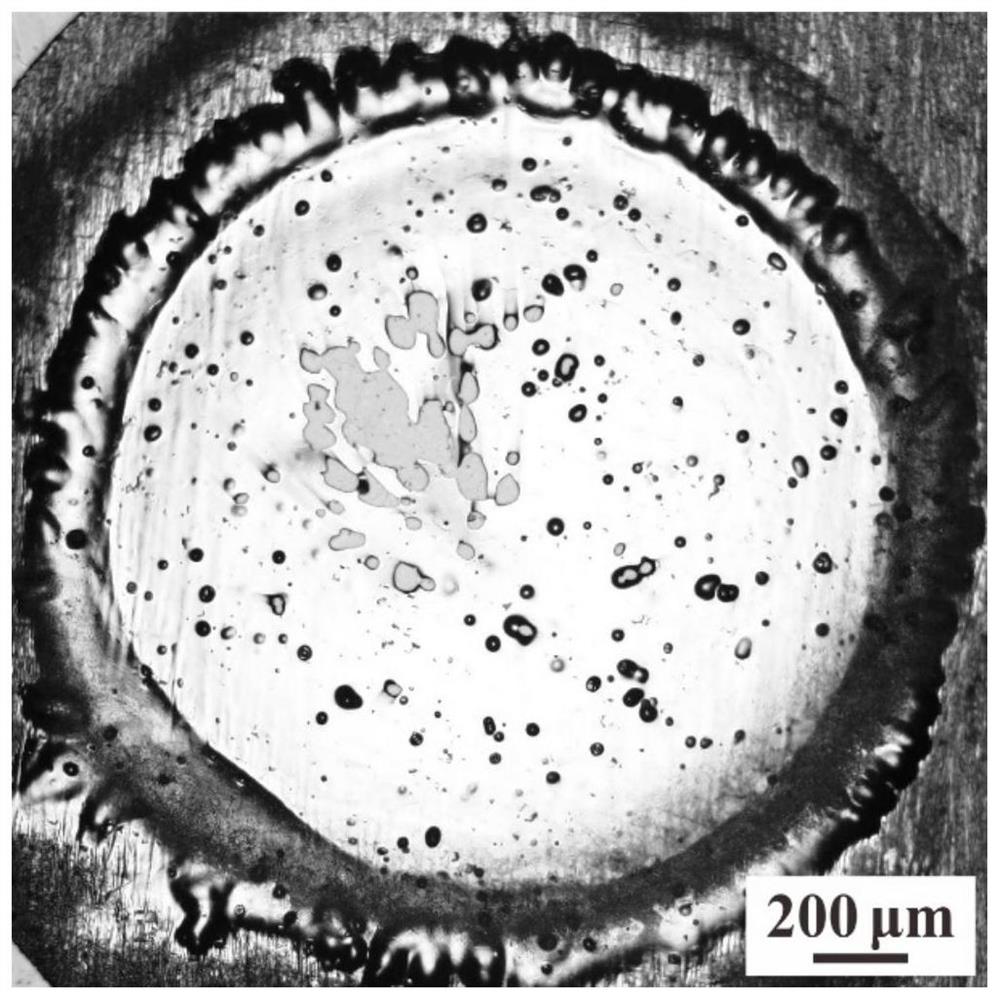

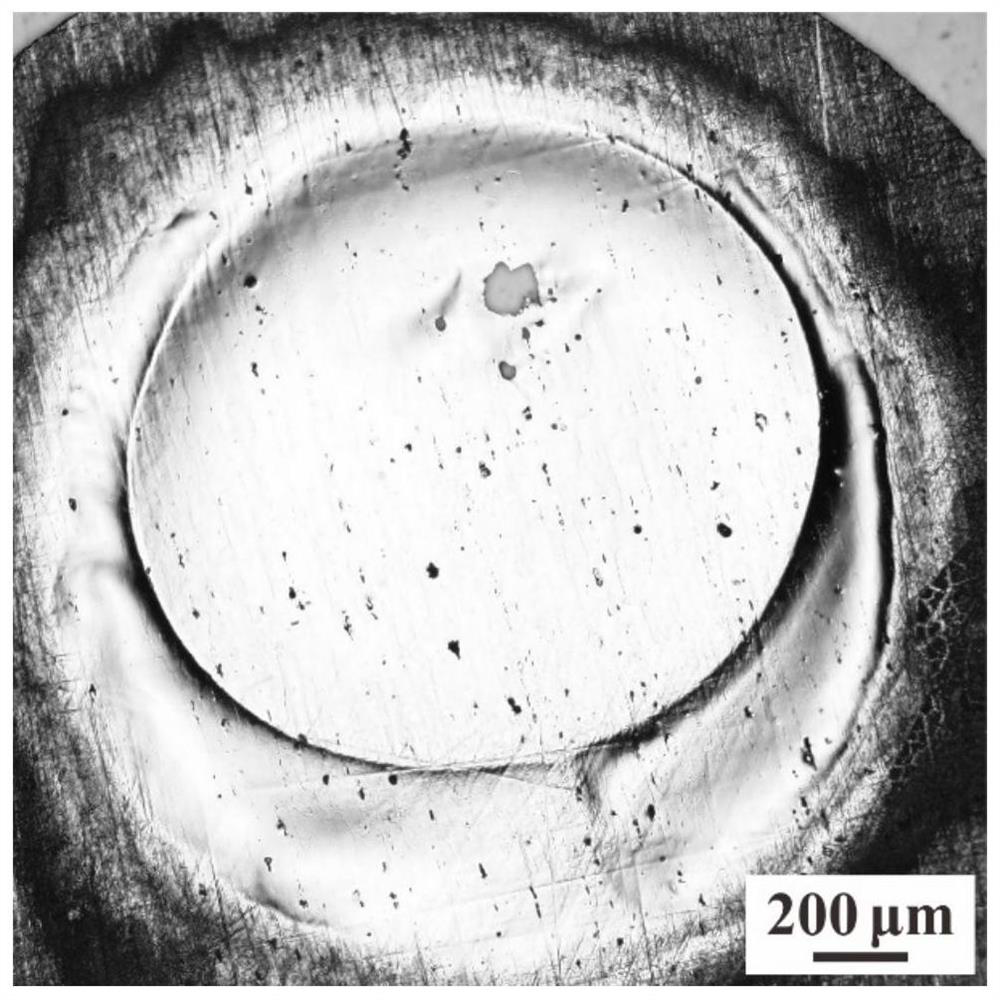

[0030] Below in conjunction with embodiment the present invention is described in more detail. In this example, a sample of 2024 aluminum alloy aged at 180°C for 120 hours is used as an example to prepare a transmission sample. The specific steps are as follows:

[0031] Step 1: Use a wire electric discharge machine to cut a metal sheet with a thickness of 500um from the block sample, and use 400#, 800#, 1200#, 2000# sandpaper to mechanically thin the sample to a thickness of 40um to 50um. During the sample grinding process, a smooth and flat glass plate was placed under the sandpaper, and the rubber was used to drag the sample to grind on the sandpaper with an "8" track, and the mechanically thinned sample was punched through a punch to obtain a 3mm diameter sample. metal disc;

[0032] Step 2: In this example, the TenuPol-5 electrolytic double-spray instrument of Struers Company was used to carry out the double-spray experiment. In the electrolytic cell of the double-jet t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com