Wafer cleaning method after chemical milling

A technology of wafer cleaning and chemical machinery, applied in the direction of chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils, etc., capable of solving problems such as BTA residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

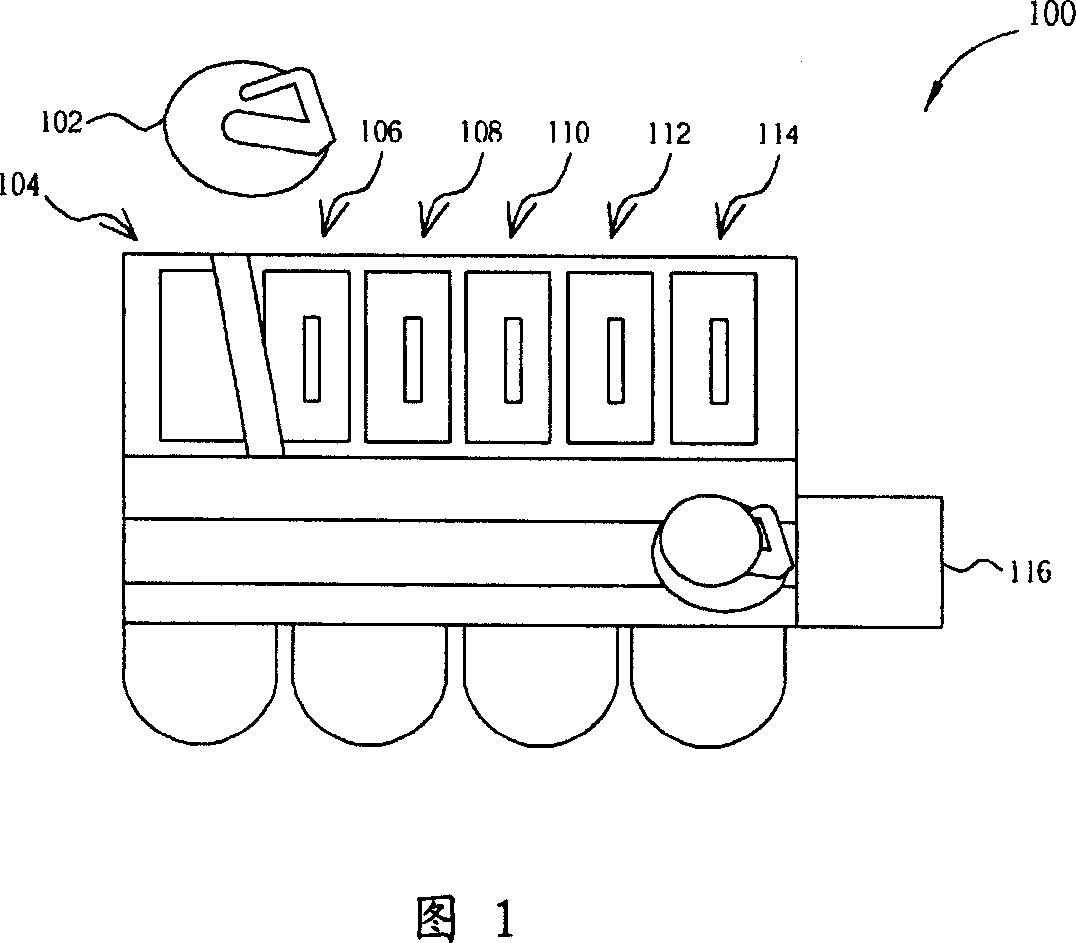

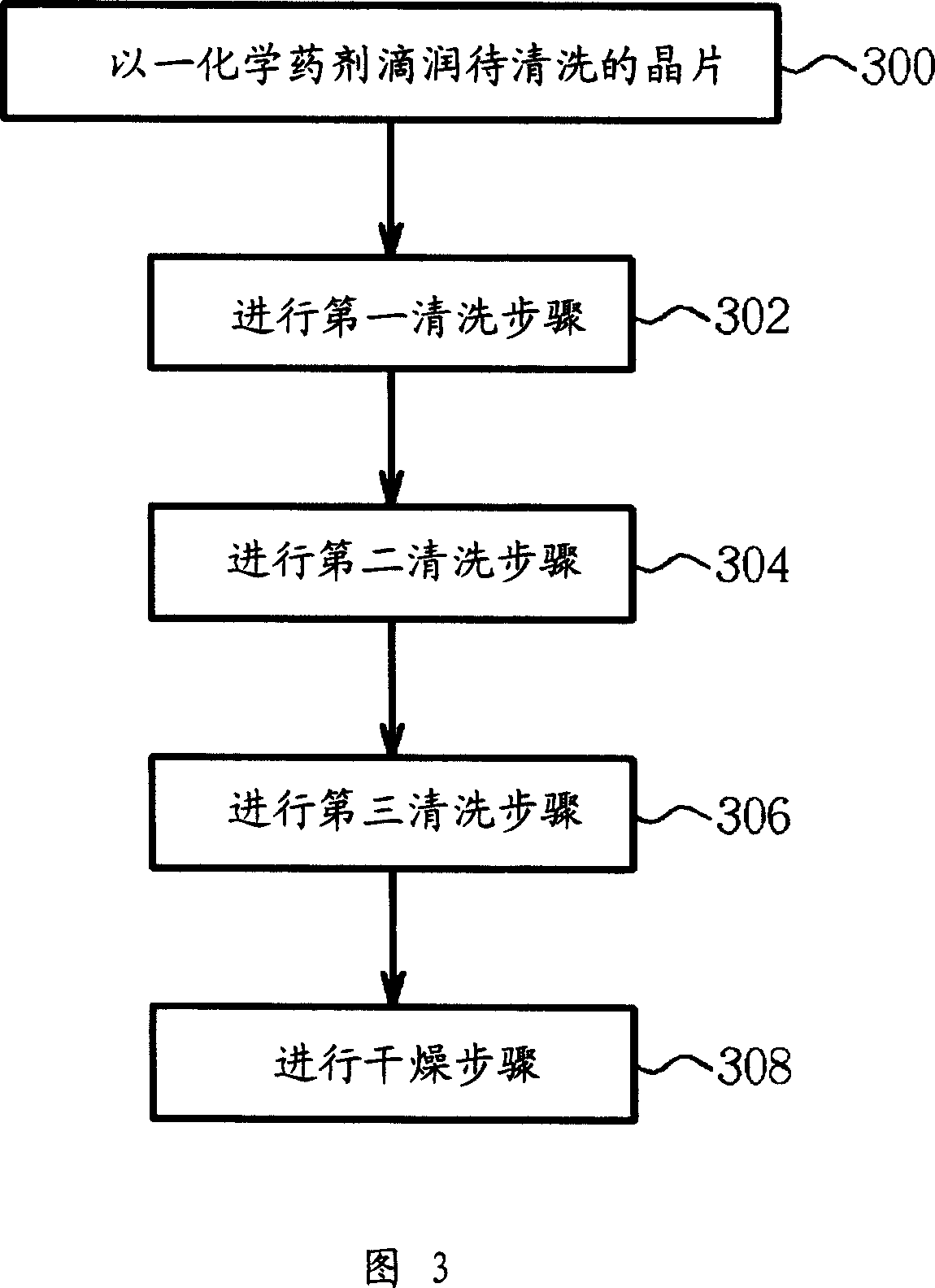

[0010] Please refer to FIG. 3, which is a flowchart of a preferred embodiment of the present invention; and please also refer to FIG. 4, which is a schematic diagram of a cleaning machine provided by a preferred embodiment of the present invention. Before cleaning the chemically polished wafer, firstly, as described in step 300 , the chemically mechanically polished wafer is placed in the buffer unit 400 of the cleaning machine for subsequent cleaning process. In step 300, chemicals are slowly dripped or sprayed on the surface of the wafer while waiting for the cleaning process to keep the surface of the wafer moist, and at the same time reduce the adhesion of BTA on the surface of the wafer, thereby preventing the wafer from waiting in the buffer unit 400 for too long Long and make the follow-up cleaning process less effective. The chemical agent can be an acidic solution such as citric acid, an alkaline solution such as an amine-containing alkaline solution, or an organic so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com