Line laser based laser engraving line feature extraction method

An extraction method, line laser technology, applied in the field of laser measurement, can solve limitations and other problems, and achieve the effect of accurate feature point position and high robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

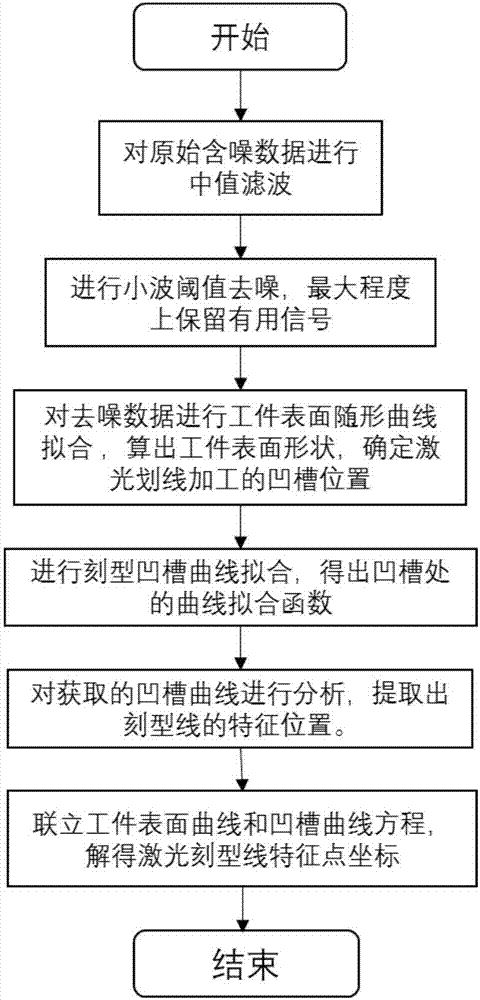

Method used

Image

Examples

Embodiment 1

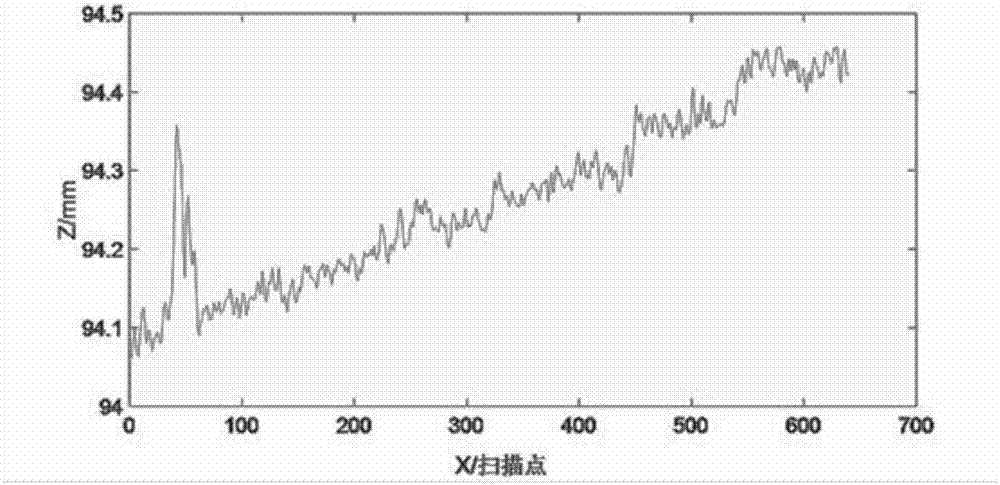

[0050] Embodiment 1, the tested object of the present invention is a 600*800mm aluminum sample plate with a flatness of 0.01mm. It has the engraved line boundary left after chemical milling and cutting, and the laser is projected on the surface of the part. Through the KEYNECE laser sensor and its blue laser, the original signal data is obtained and processed as the original noise-containing signal. The obtained original noisy signal is attached as figure 2 shown. then follow the attached figure 1 The flow chart shown proceeds as follows.

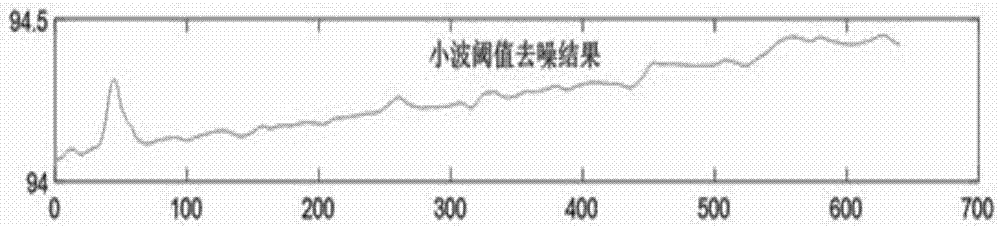

[0051] The first step is signal preprocessing based on median filtering and wavelet threshold denoising. Median filtering is performed on the original noisy data signal. First define a long sliding window. If the signal sample value in the window at a certain moment is {x(i-N),...,x(i),...,x(i+N)}. The signal values in the window are sorted from small to large, and the median value is taken as the output value of the filter, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com