Rapid manufacturing method used for outer storing box gridding wallboard of aerospace craft

A technology for aerospace vehicles and manufacturing methods, which is applied in the field of aerospace aluminum alloy structure manufacturing, and can solve problems such as grid panels for external storage tanks of aerospace vehicles that have not yet been seen, achieve excellent shear resistance, uniform composition, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1: Processing method of pre-welded grid structure with rib shape:

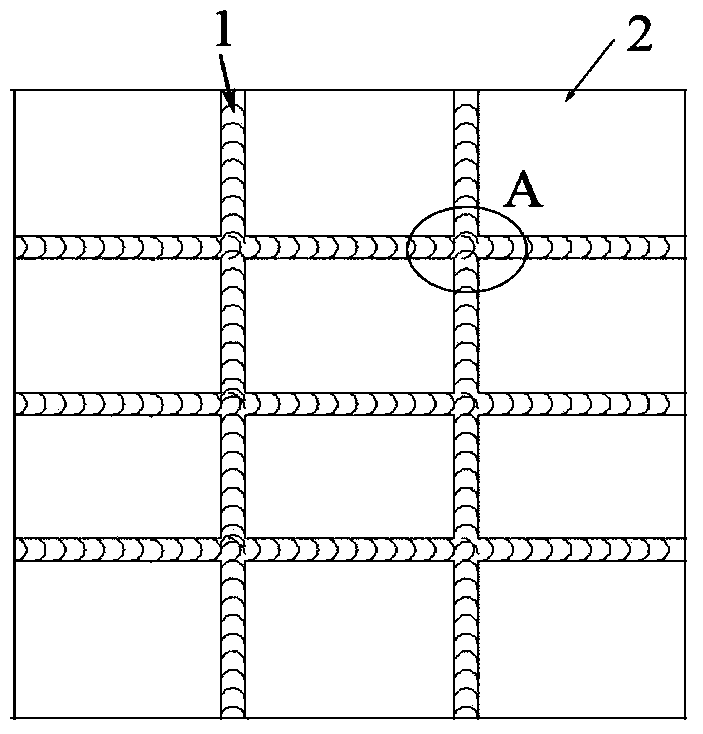

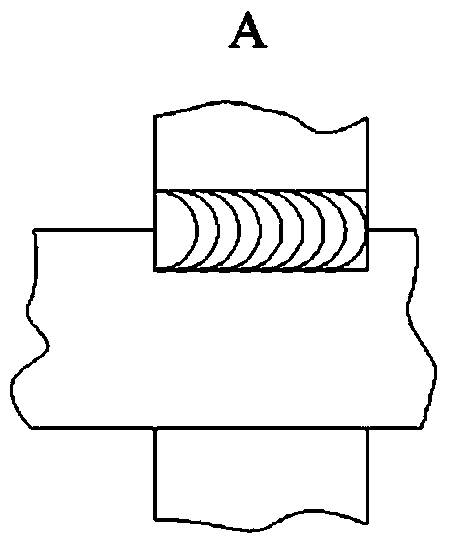

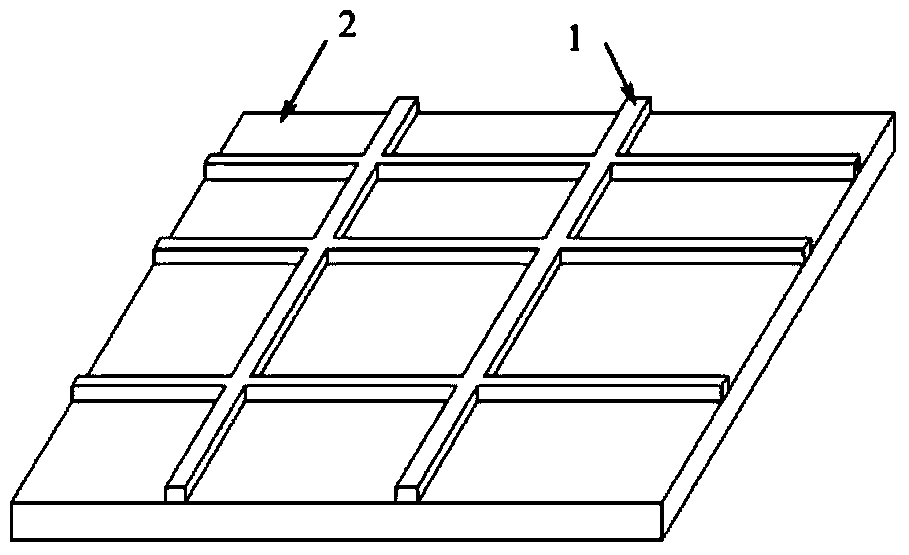

[0065] Processing on the 8mm×690mm×690mm base plate such as Picture 1-1 The distribution grid shown is welded with a rib width of 30mm and a grid depth of 8mm. First, the 4mm thick aluminum alloy plate is cut to obtain (1) 8 aluminum plates of 150mm×30mm in size, and (2) 3 aluminum plates of 690mm×30mm in size. Arrange the aluminum plates 1 symmetrically on both sides of the aluminum plate 2, and the distribution is as follows Picture 1-1 Shown. Use a stirring head with a shaft shoulder diameter of 12mm and a stirring needle length of 3.5mm to complete such Figure 1-2 There are six sets of corner joints shown in. Get after welding figure 2 The structure of rib 1 is shown in. Repeat the above steps to complete the welding of the second set of ribs 1.

[0066] First, a set of ribs 1 is arranged on the bottom plate 2, and assembled and clamped by friction stir welding lap clamps. The overlapping p...

Embodiment 2

[0068] Example 2: Processing method of grid structure formed by welding ribs on a whole aluminum plate:

[0069] The required meshed siding such as Figure 3-1 with Figure 3-2 As shown, the method in this embodiment does not need to separately process the rib structure in advance. Instead, two aluminum plates 3 and 4 with the same length and width as the bottom plate are placed on the bottom plate. It is assembled and fixed by friction stir welding lap clamp. According to the grid layout, such as Figure 3-1 As shown, the main purpose of marking the surface of the aluminum plate 3 is to mark the position of the ribs in the grid. After finishing the preparatory work, select the welding parameters: rotation speed 900rpm, welding speed 80mm / min, shaft shoulder diameter 30mm, stirring needle length 9.5mm. According to the marking area to complete the friction stir welding of the structure, the overlap of multiple lap welds should also be considered. It can be set as two welds, and...

Embodiment 3

[0071] Example 3: Processing method of grid structure with different reinforcing rib material and base plate material

[0072] The processing dimensions are as given in Example 3. The material of the bottom plate 5 is 2024 aluminum alloy. This aluminum alloy has good plasticity and is suitable for outer storage tank wall panels with good ductility. 7075 aluminum alloy is selected for the material of the lap board 3 and 4, which has high strength. As a reinforcing rib, the wall board can have high strength on the basis of high plasticity to resist external impact and friction. . In this embodiment, the friction stir welding dissimilar aluminum alloy lap joint technology is applied to the grid structure processing of the outer tank wall, and the welding parameters and processing steps are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com