Chemical milling technology for surface plasticity deformation layer of single crystal cast blade

A single crystal blade and blade technology, which is applied in the field of layered milling of plastic deformation on the surface of single crystal casting blades, to prevent recrystallization, improve reliability, and have no defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

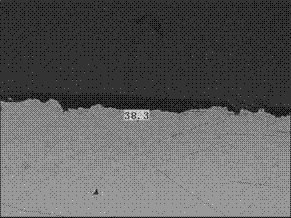

Image

Examples

Embodiment 1

[0028] (1) Surface treatment of blades: washing with water to remove excess on the blade surface;

[0029] (2) Heat the wax composed of paraffin wax, yellow wax and rosin to 70°C. After the wax is completely melted, use absorbent cotton dipped in wax to seal the small holes of the leaves, then apply wax to the parts of the leaves that need to be protected, and finally remove the excess wax;

[0030] (3) Carry out chemical milling treatment on blades: use chemical milling liquid to carry out chemical milling treatment on blades. The area of the blade is 0.2dm 2 / l, each component in the chemical milling liquid of unit volume is made up of: 150ml / l nitric acid, 80ml / l hydrochloric acid, 80ml / l hydrofluoric acid, 150g / l ferric chloride, 40ml / l acetic acid, 0.3g / l ten Dialkyl sodium sulfate, 15g / l activated carbon, when the blade area treated by unit volume chemical milling fluid is 2dm 2 / l, replace the chemical milling fluid;

[0031] (4) After the chemical milling treatme...

Embodiment 2

[0038] (1) Surface treatment of the leaves: use acetone to remove stains on the surface of the leaves;

[0039] (2) First use plastic bags to seal the small holes in the leaves, use absorbent cotton dipped in paint to seal the larger holes in the leaves, then paint the parts of the leaves that need to be protected, and then paint the second time after drying at room temperature , and finally remove excess paint, the paint used is AC-850 paint;

[0040] (3) Carry out chemical milling treatment on the blade: use chemical milling liquid to carry out chemical milling treatment on the blade, the chemical milling temperature is 35°C, the chemical milling speed is 3.0 μm / min, the chemical milling depth is 50 μm, and each unit volume of chemical milling fluid treatment The area of the blade is 0.2dm 2 / l, each component in the chemical milling liquid of unit volume is made up of: 200ml / l nitric acid, 100ml / l hydrochloric acid, 100ml / l hydrofluoric acid, 180g / l ferric chloride, 40ml...

Embodiment 3

[0046] (1) Surface treatment of blades: washing with water to remove excess on the blade surface;

[0047] (2) First use adhesive tape to seal the small holes in the blade, use absorbent cotton dipped in paint to seal the larger holes in the blade, then paint the part of the blade that needs to be protected, and then paint the second time after drying at room temperature. Finally remove excess paint, the paint used is AC-850 paint;

[0048] (3) Carry out chemical milling treatment on blades: use chemical milling liquid to carry out chemical milling treatment on blades. The area of the blade is 0.2dm 2 / l, each component in the chemical milling fluid per unit volume consists of: 200ml / l nitric acid, 100ml / l hydrochloric acid, 100ml / l hydrofluoric acid, 200g / l ferric chloride, 50ml / l acetic acid, 0.6g / l deca Dialkyl sodium sulfate, 20g / l activated carbon, when the area of blades treated by unit volume chemical milling fluid is 2.5dm 2 / l, replace the chemical milling fluid;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com