Method for modifying iron-molybdenum catalyst for oxidizing methanol to formaldehyde

A catalyst and oxidation technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve complex production processes, increased catalyst preparation costs, and large solvent consumption Water and other problems, to achieve the effect of simple process, high methanol conversion rate and formaldehyde selectivity, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

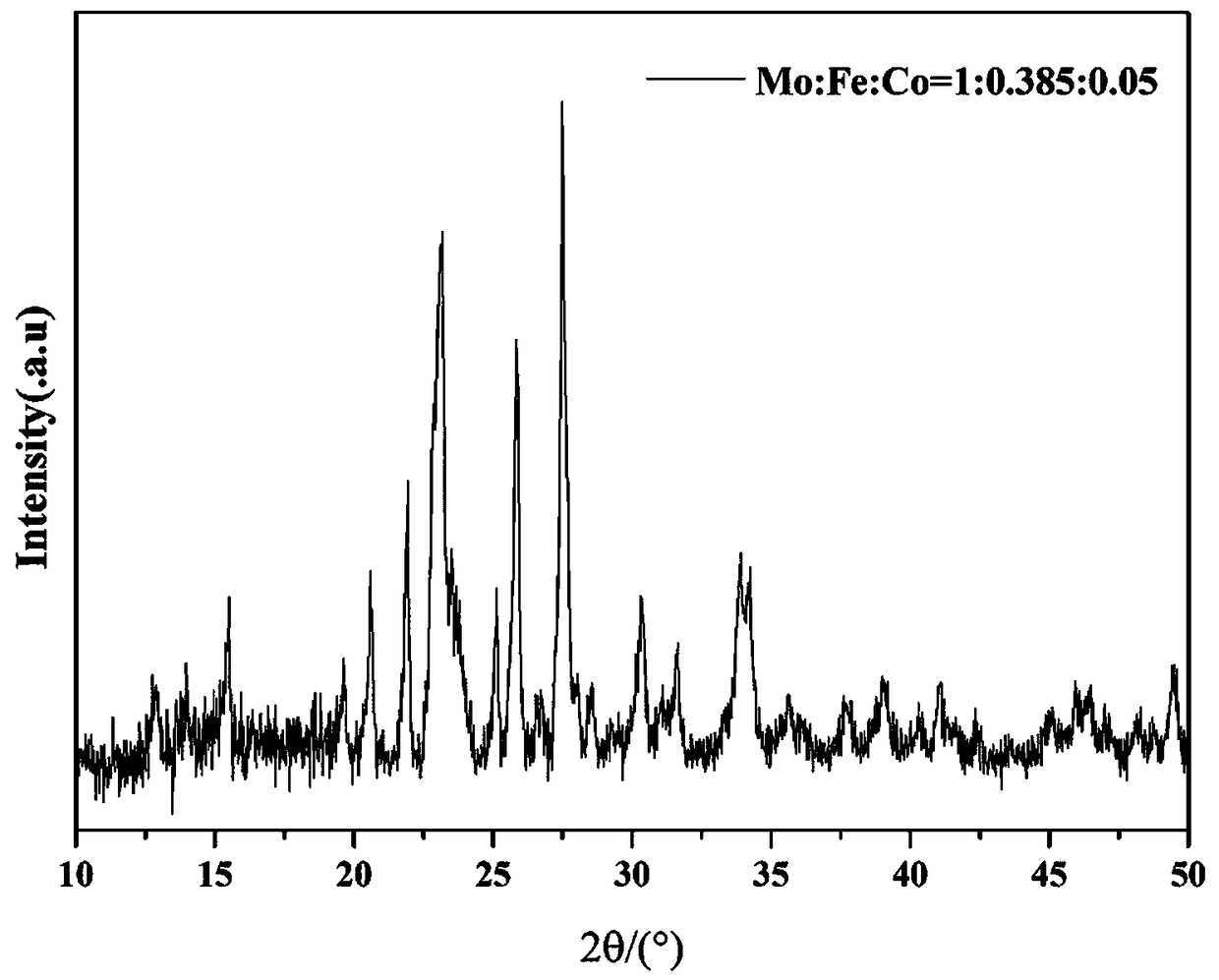

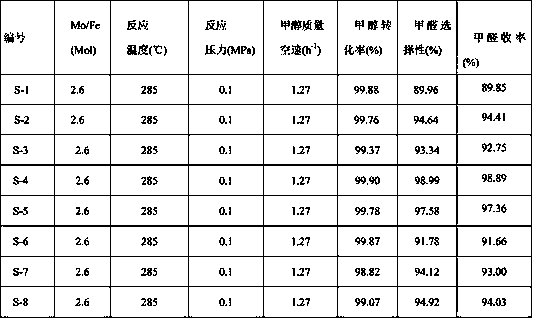

[0021] Embodiment 1, the modification method of this methanol oxidation to formaldehyde iron-molybdenum catalyst is carried out according to the following steps: the first step, by molybdenum: iron: the molar ratio of metal promoter salt is 1: 0.2 to 0.67: 0.01 to 0.2, Mix molybdate, iron salt and metal additive salt evenly to obtain a mixture; in the second step, the mixture is ball-milled by a ball mill to obtain a ball mill; in the third step, the ball mill is dried and cooled to obtain an iron-molybdenum catalyst precursor In the fourth step, the iron-molybdenum catalyst precursor is calcined to obtain the iron-molybdenum catalyst for the oxidation of methanol to formaldehyde. In Example 1, the proportion of balls (mass ratio of large and small balls) can range from 1 / 0 to 0 / 1; a green and efficient modification method of methanol oxidation to formaldehyde iron molybdenum catalyst according to the present invention, first according to a certain Mo : Fe : molar ratio of met...

Embodiment 2

[0022] Embodiment 2, as the optimization of above-mentioned embodiment, molybdate is soluble molybdate, and molybdate is one or one in heptamolybdate, tetramolybdate, dimolybdate and monomolybdate a mixture of the above.

Embodiment 3

[0023] Embodiment 3, as an optimization of the above embodiment, the iron salt is a soluble iron salt, and the iron salt is one or more mixtures of ferric nitrate, ferric sulfate and basic ferric acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com