Hybridized particle, polymer-based composite material, their preparation methods and use of polymer-based composite material

A technology of hybrid particles and composite materials, applied in the field of polymer-based composite materials and their preparation, can solve the problems of increased dielectric loss of composite materials, energy loss, and reduced withstand voltage strength of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The first preparation method: the above-mentioned hybrid particles are prepared by mechanical ball milling, and the method includes the following steps:

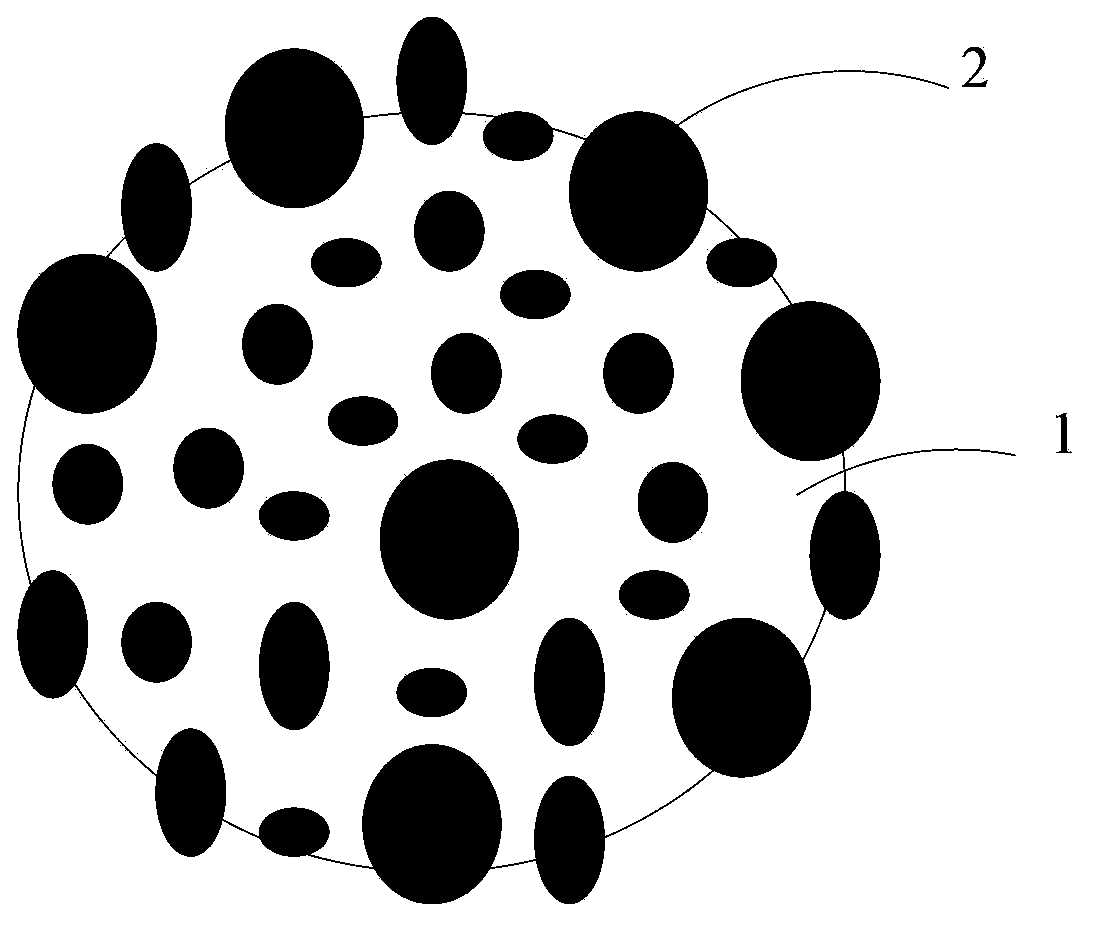

[0051] The hybrid particles are obtained by ball milling the insulating ceramic particles 1, the conductive particles 2, a solvent, a surfactant, and a pH regulator.

[0052] In the above steps of the mechanical ball milling method, the conductive particles 2 with slightly smaller particle size and higher surface energy are physically adsorbed and combined with the insulating ceramic particles 1 during the ball milling process to obtain hybrid composite particles. The synergistic effect of the surfactant and the pH regulator makes the structure of the prepared hybrid particle stable. Among them, the surfactant can effectively improve the surface energy of the conductive particles 2 and the insulating ceramic particles 1, and its added amount is 0.5-5% of the total mass of the insulating ceramic particles 1 and the con...

Embodiment 1

[0083] A barium titanate hybrid particle with silver conductive silver particles loaded on the surface, the preparation process of which is as follows:

[0084] Weigh 100nm BaTiO 3 5g, AgNO 3 5g and 300ml of ethylene glycol were mixed into a 500ml three-necked flask, and the BaTiO 3 The particles are evenly dispersed, and the three-necked flask is connected with a thermometer and a cooling water condensing device. Heating in an oil bath, raising the temperature from room temperature to 140°C took 25 minutes, then 140 minutes and keeping it warm for 20 minutes, then cooling down to room temperature, centrifuging, cleaning, and drying naturally to obtain 7.5g of gray powder, which is the surface of titanium loaded with silver conductive silver particles. Barium acid hybrid particles.

[0085] Carry out SEM and TEM analysis respectively to the barium titanate hybrid grain that the surface load silver conductive silver particle of present embodiment 1 prepares, the result of SE...

Embodiment 2

[0087] A barium titanate hybrid particle loaded with conductive carbon particles on the surface, the preparation process of which is as follows:

[0088] Weigh 100nm BaTiO 3 20g, glucose 1g, add 20g of distilled water, ultrasonically stir to disperse evenly, put it in a drying oven for 24 hours, then put it into the N 2 Heating in a protected muffle furnace, the heating curve is from room temperature at 5°C / min to 100°C for 1 hour, then at 5°C / min to 400°C for 2 hours and then cooling down naturally to obtain a black powder, namely It is a barium titanate hybrid particle loaded with carbon conductive particles on the surface.

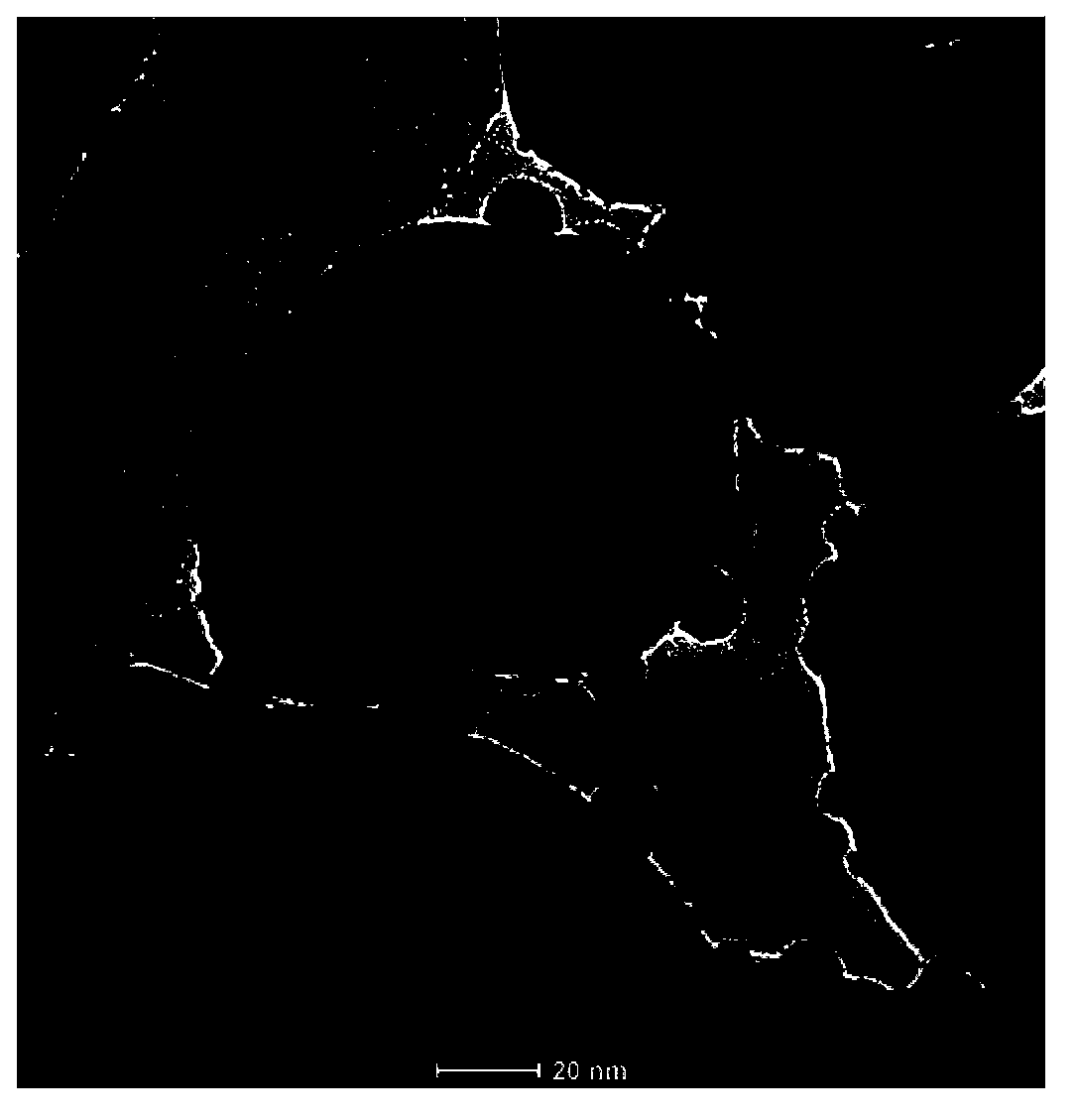

[0089] The barium titanate hybrid particles loaded with conductive carbon particles on the surface prepared in Example 2 were analyzed by SEM and TEM respectively, and it was found that the BaTiO in the hybrid particles 3 The particle size is 100nm and the shape is spherical, and the conductive carbon particles carried on the surface have a particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com