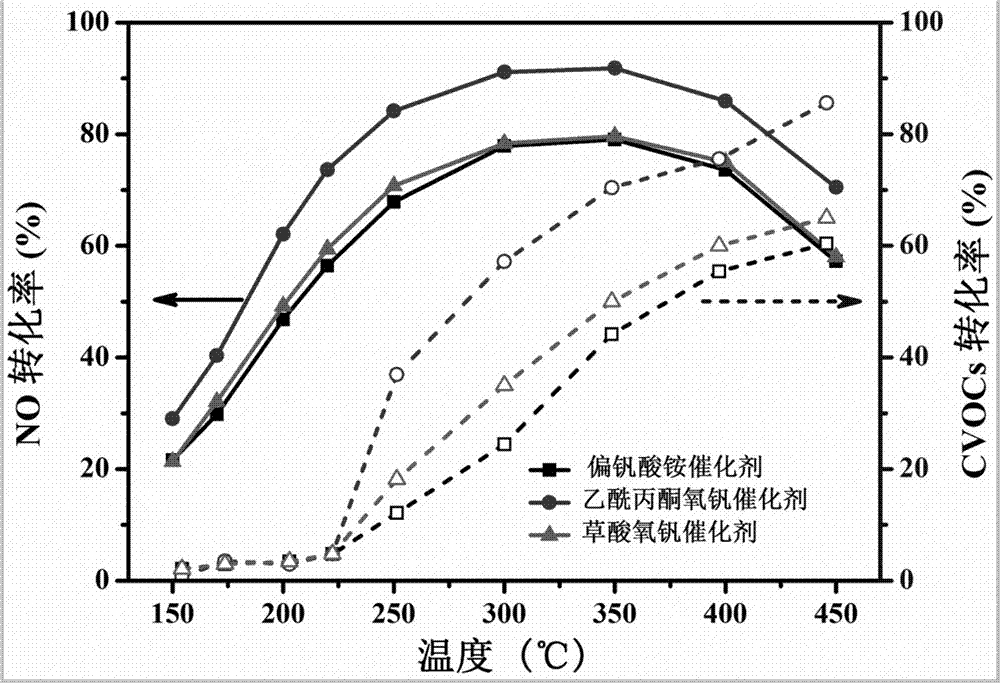

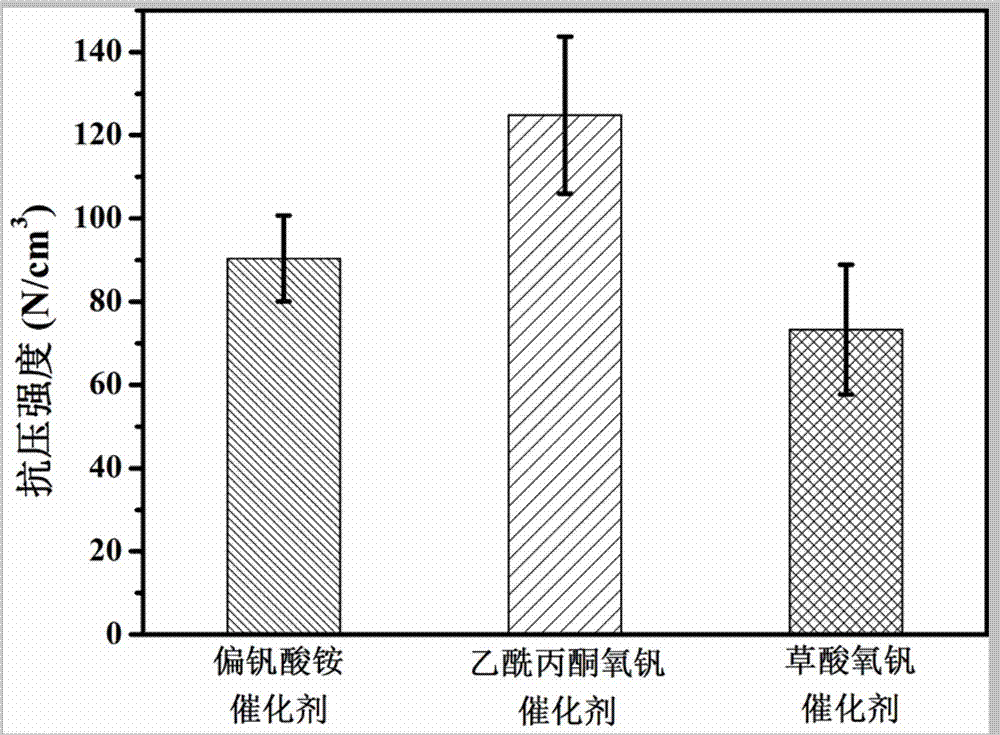

Preparation method and application of trifolium-shaped catalyst for cooperatively controlling NOx and CVOCs

A collaborative control and catalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of increased bed pressure drop, difficult industrial applications, loading and unloading Inconvenience and other problems, to achieve the effect of high mechanical strength, high denitrification rate, wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Preliminarily mix 200g of titanium dioxide and 15g of ammonium metavanadate, and then put them into a ball mill tank for ball milling, milling for 30 minutes, with a speed of 40 rpm;

[0034] Step 2: taking out the ball mill mixture and drying it at 110°C for 4 hours, and roasting at 500°C for 4 hours in an air atmosphere to obtain a powder catalyst;

[0035] Step 3: Add 200g of powder catalyst and 6.2g of fiber prepared in Step 2 into the kneader, stir and gradually add 60mL of water, and keep stirring for 30min;

[0036] Step 4: Add 0.5g of stearic acid, 2.4mL of lactic acid, 1.7g of polyethylene oxide (PEO) and 2.0g of carboxymethyl cellulose (CMC) into the kneader step by step, with an interval of 30 minutes between each step, and keep stirring to obtain a wet material group;

[0037] Step 5: Install a clover-shaped mold, use an extruder to extrude the wet dough obtained in Step 4, dry at room temperature for 24 hours, and heat up rapidly at 10°C / min to 110...

Embodiment 2

[0041] Step 1: Preliminarily mix 200g of titanium dioxide and 34g of vanadyl acetylacetonate, and then add it to a ball milling tank for ball milling for 30 minutes at a speed of 40 rpm;

[0042] Step 2: taking out the ball mill mixture and drying it at 110°C for 4 hours, and roasting at 450°C for 4 hours in an air atmosphere to obtain a powder catalyst;

[0043]Step 3: Add 200g of powder catalyst and 6.2g of fiber prepared in Step 2 into the kneader, stir and gradually add 80mL of water, and keep stirring for 50min;

[0044] Step 4: Add 1.5g of stearic acid, 4.8mL of lactic acid, 1.0g of polyethylene oxide (PEO) and 1.0g of carboxymethyl cellulose (CMC) into the kneader step by step, with an interval of 30 minutes between each step, and keep stirring to obtain a wet material group;

[0045] Step 5: Install a clover-shaped mold, use an extruder to extrude the wet dough obtained in step 4, dry at room temperature for 24 hours, and heat up rapidly at 10°C / min to 110°C at room t...

Embodiment 3

[0049] Step 1: Preliminarily mix 200g of titanium-tungsten powder and 20g of vanadyl oxalate, and then put it into a ball mill tank for ball milling, ball milling for 30 minutes, and the speed is 80 rpm;

[0050] Step 2: taking out the ball mill mixture and drying it at 110°C for 4 hours, and roasting at 500°C for 4 hours in an air atmosphere to obtain a powder catalyst;

[0051] Step 3: Add 200g of powder catalyst and 6.2g of fiber prepared in Step 2 into the kneader, stir and gradually add 60mL of water, and keep stirring for 30min;

[0052] Step 4: Add 0.5g of stearic acid, 2.4mL of lactic acid, 1.7g of polyethylene oxide (PEO) and 2.0g of carboxymethylcellulose (CMC) into the kneader step by step, with an interval of 30 minutes between each step, and keep stirring to obtain a wet material group;

[0053] Step 5: Install a clover-shaped mold, use an extruder to extrude the wet dough obtained in step 4, dry at room temperature for 24 hours, and heat up rapidly at 10°C / min t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com