Heat pipe cyclic power machine

A heat pipe cycle and power machine technology, applied in the field of power machines, can solve the problems of poor power generation efficiency of power generation coils, poor heat conduction and power generation effects, and low device efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

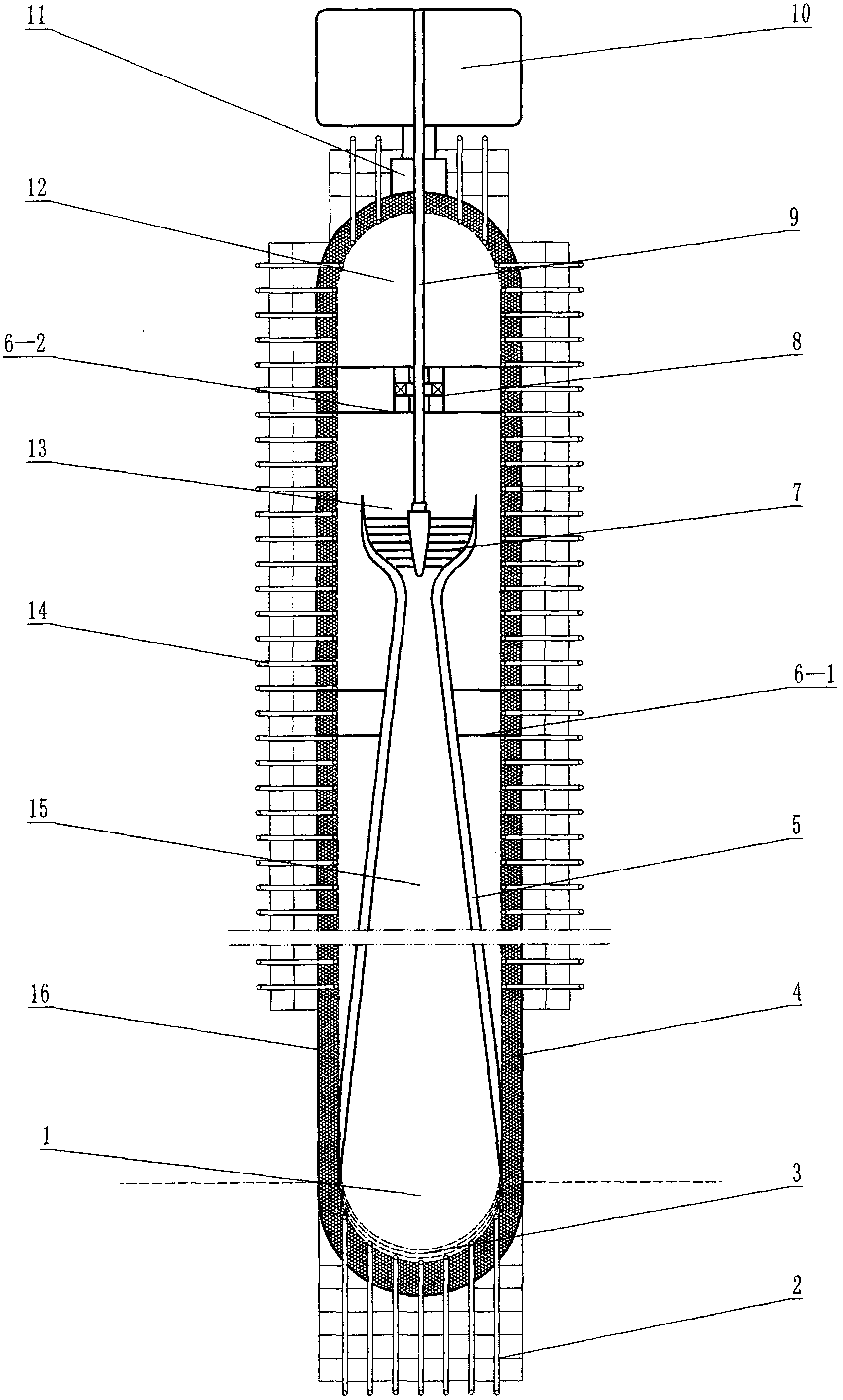

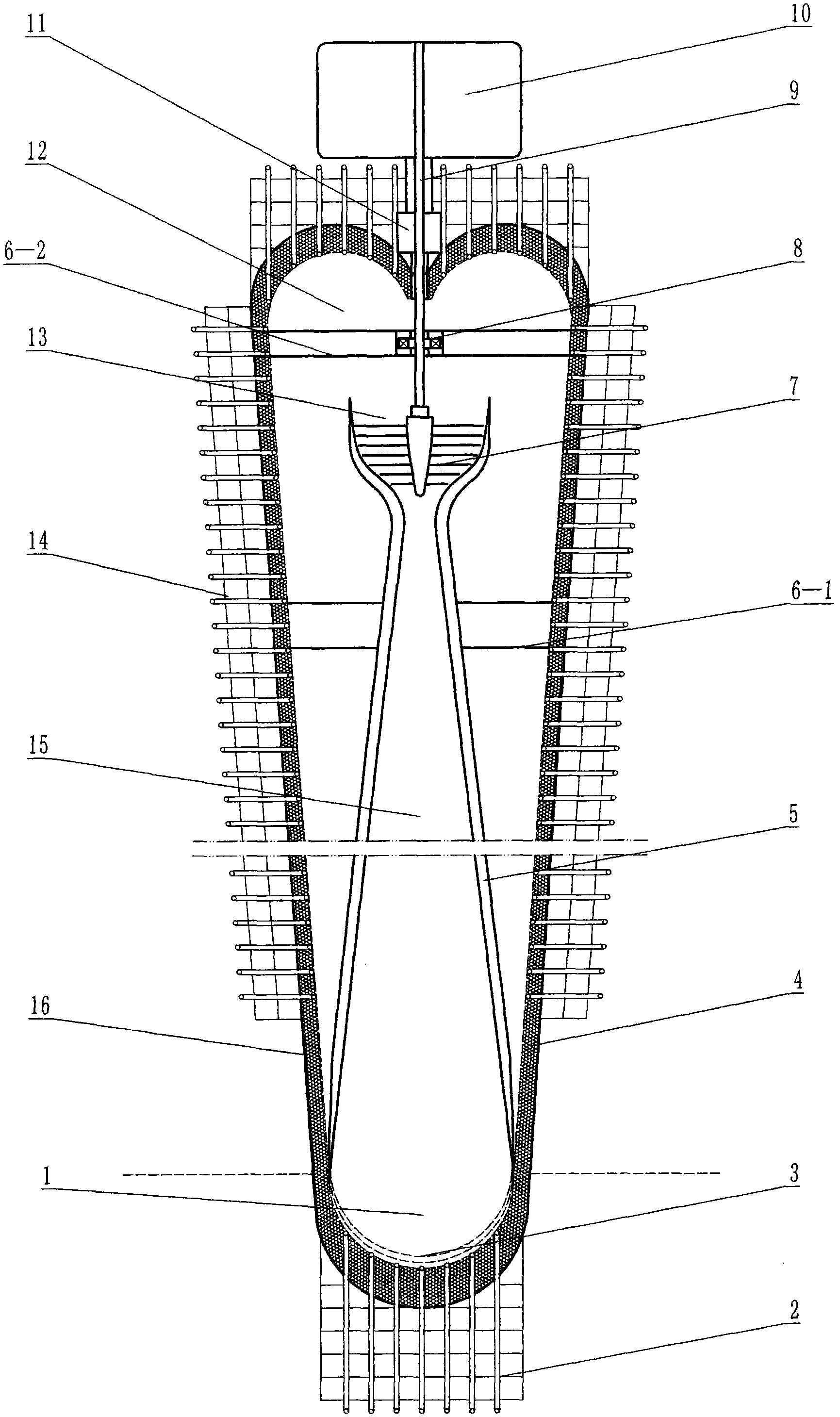

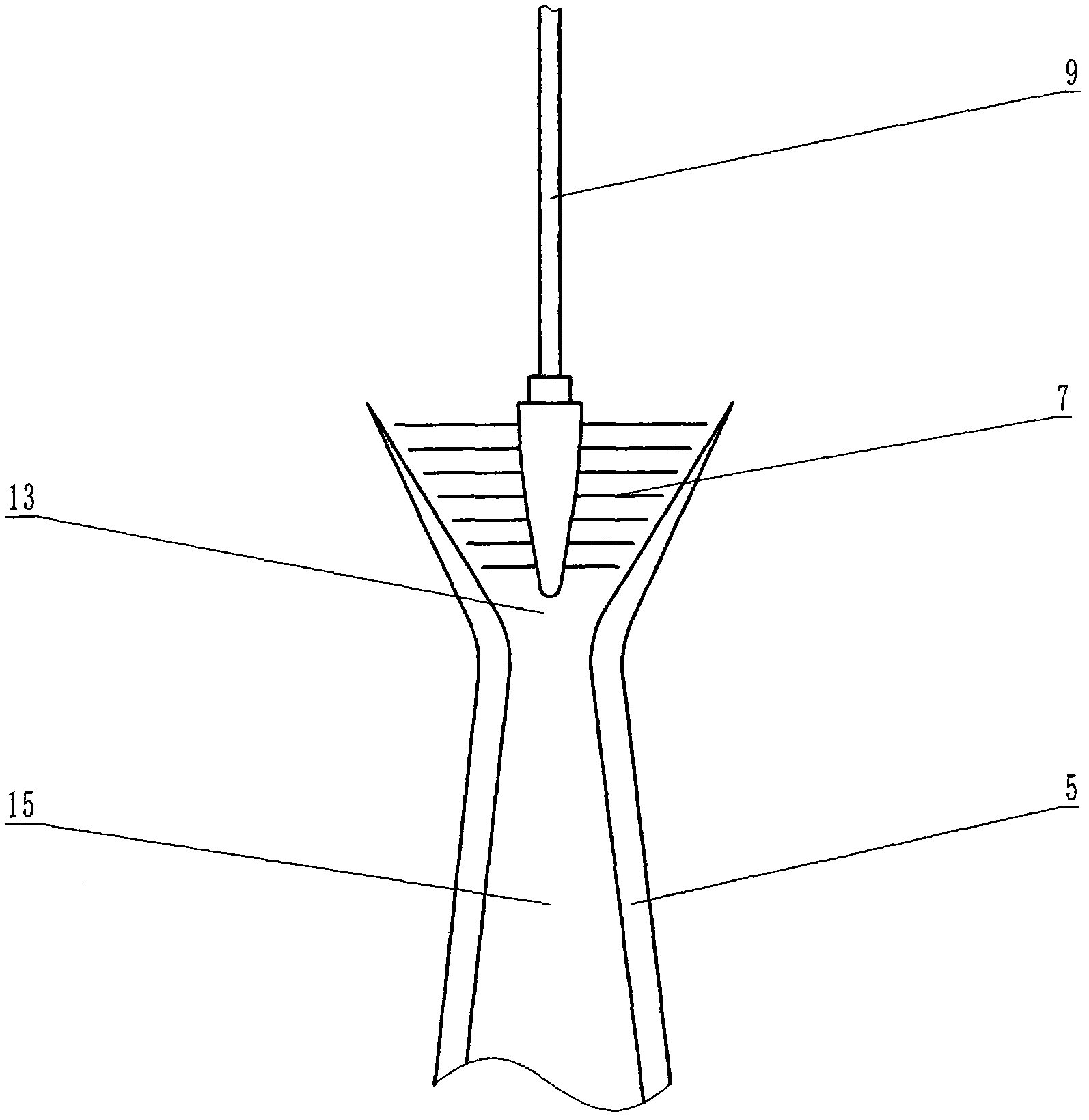

[0021] As shown in the accompanying drawings: the heat pipe cycle power machine is composed of a heat pipe and a turbine power generation system. The body of the heat pipe is composed of the pipe wall 16, the liquid-absorbing core 4 and the working medium 3; The inner surface of the tube wall 16 of the heat pipe is provided with a liquid-absorbing wick 4 with a larger volume, surface area and permeability, and a smaller capillary effective radius. The axial vertical section of the liquid-absorbing core 4 on the inner surface of the pipe wall 16 on the upper part of the condensation chamber 12 is larger than the axial vertical section of the liquid-absorbing core 4 in other parts, and can be set as a meniscus-shaped liquid-absorbing section. core. The inner cavity of the lower part of the heat pipe is the evaporation chamber 1, which is filled with the working fluid 3, and the inner cavity from the evaporation chamber 1 to the nozzle 13 is a tapered lumen 15 with a gradually d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com