Miniaturized broadband slow-wave half-mode substrate-integrated waveguide coupler and design method thereof

A half-mode substrate integration and coupler technology, which is applied in the field of couplers, can solve the problems that the conduction characteristics cannot be adjusted twice, the coupling structure of the coupler is single, and the design freedom is low, so as to achieve the controllable phase velocity of the guided wave, good Coupling performance, the effect of controllable operating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

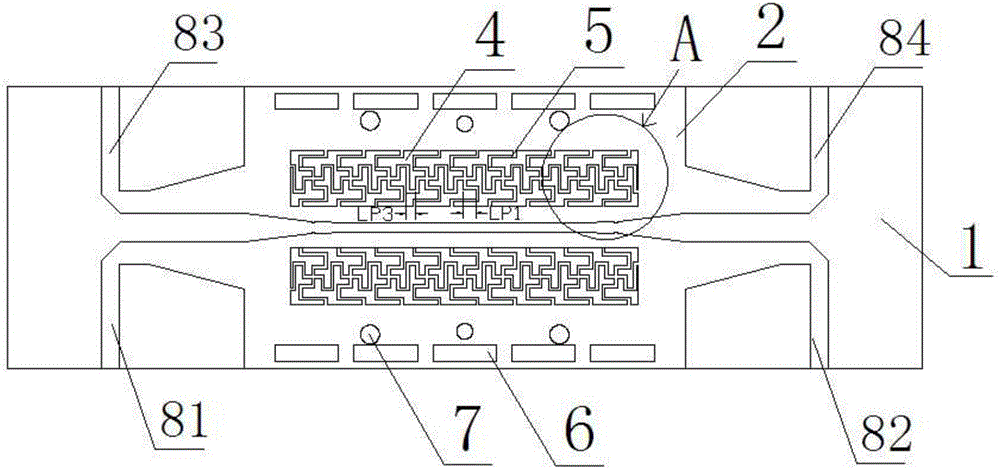

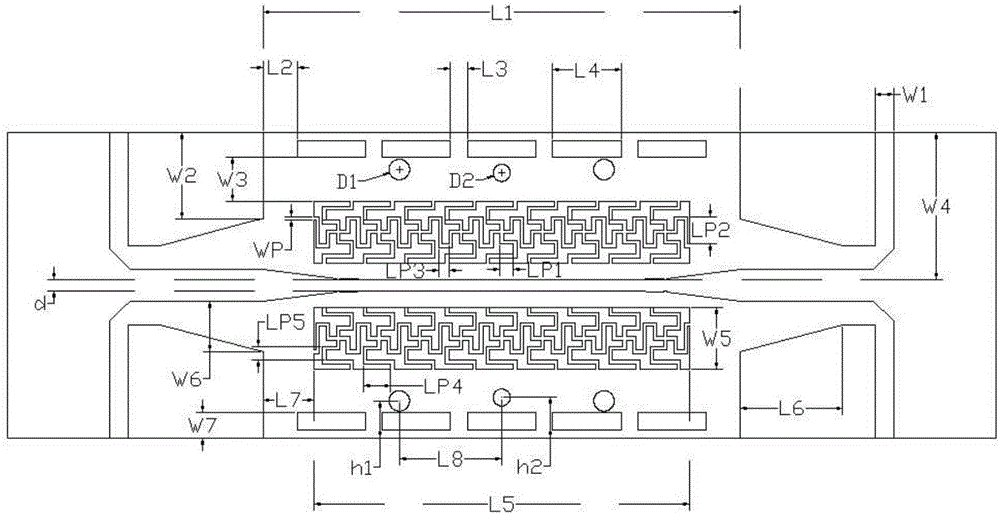

[0038] The slow-wave half-mode substrate-integrated waveguide coupler is the SW-HMSIW coupler. Such as figure 1 A miniaturized broadband slow-wave half-mode substrate-integrated waveguide coupler as shown, including a dielectric substrate 1, the upper and lower surfaces of the dielectric substrate 1 are metal coatings, and the entire lower surface of the metal coating on the lower surface is used as a ground plane The upper surface is processed and etched by the printed circuit board process, and the shape is two mutually symmetrical and non-contact half-mode substrate integrated waveguide transmission lines 2. The inner side of the half-mode substrate integrated waveguide transmission line 2 is opened with a loading window 4, and the passage through the loading window 4 The PCB is etched into a microstrip multi-segment line network 5, and the microstrip multi-segment line network 5 forms a hollow pattern structure; the outer side of the half-mode substrate integrated waveguid...

Embodiment 2

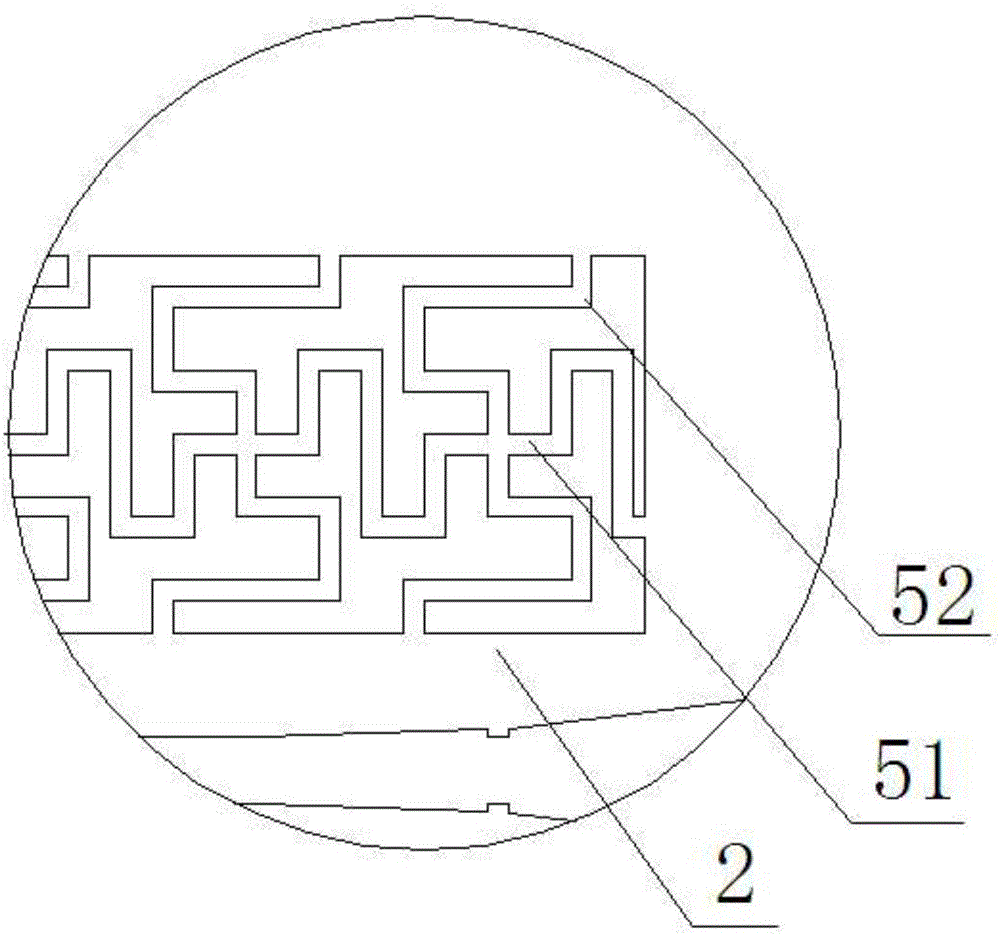

[0040] This embodiment optimizes the structures of the microstrip polyline network 5 and the loading window 4 on the basis of the above embodiments.

[0041] The loading window 4 is rectangular. The microstrip polyline network 5 includes a plurality of cross-shaped microstrip nodes 51 arranged in sequence along the rectangular loading window, that is, a single-row structure is formed along the horizontal direction. The port is connected with a longitudinal microstrip multi-segment line; the transverse microstrip multi-segment line realizes the connection between two adjacent microstrip nodes 51 and the microstrip nodes 51 at both ends are connected to the half-mode substrate integrated waveguide transmission line 2; the longitudinal microstrip The polyline is connected between the microstrip node 51 and the half-mode substrate integrated waveguide transmission line 2, and the microstrip polyline network 5, the transverse microstrip polyline and the vertical microstrip polyline...

Embodiment 3

[0045] This embodiment is further improved on the basis of the above-mentioned embodiments, that is, there are multiple metallized through holes 7, the metallized through holes 7 are arranged in a row along the loading window 4, and the diameter of the metallized through hole 7 in the center is the smallest and The diameter along the two ends of the connection gradually increases, and different design requirements can replace parameters such as the number and diameter of through holes.

[0046] The electric wall can adopt the existing metallized through-hole array, and also can adopt the metallized through-groove.

[0047] The coupler includes an input terminal 81 , a through output terminal 82 , a coupling output terminal 84 and an isolation terminal 83 . The two ends of the half-mode substrate-integrated waveguide transmission line 2 are respectively connected to the input terminal 81 and the straight-through output terminal 82 through the trapezoidal microstrip transition s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com