Transparent and environment-friendly underwater consolidated solvent-free epoxy grouting material and preparation method and application thereof

A technology of grouting material and environmentally friendly water, which is applied in the field of transparent and environmentally friendly underwater solidified solvent-free epoxy grouting material and its preparation field, which can solve the problems of difficult underwater operations, difficult construction operations, and no water-resistance function , to achieve the effect of improving water resistance and comprehensive mechanical properties, good water blocking and anti-leakage, and rapid increase in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

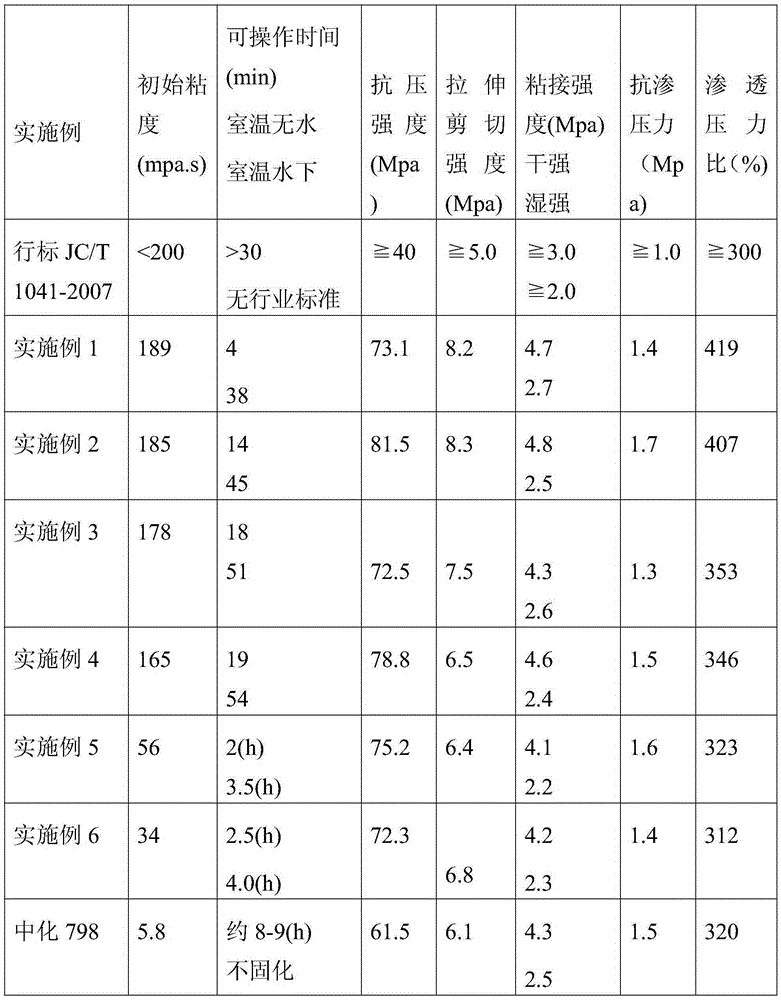

Examples

Embodiment 1

[0022] Mix 80 parts of epoxy resin E-51 with 18 parts of reactive diluent 1,4-butanediol diglycidyl ether and 2 parts of interface modifier silane coupling agent KH-570 to obtain component A; mix 64 parts of amine Stir and mix the curing agent polythiolamine R-2020, 20 parts of water-resistant dispersant and 16 parts of accelerator 2,4,6 tris(dimethylaminomethyl)phenol trioleate; The component and the second component are mixed evenly according to the weight ratio of 100:100 to obtain the epoxy grouting material.

Embodiment 2

[0024] Stir and mix 75 parts of epoxy resin F-44, 23 parts of reactive diluent 1,6-hexanediol diglycidyl ether and 2 parts of interface modifier silane coupling agent KH-550 to obtain component A; 1 part of amine curing agent cycloaliphatic amine R-2022, 15 parts of water-resistant dispersant and 5 parts of accelerator benzyldimethylamine are stirred and mixed to obtain component B; mix component A and component B according to the weight ratio of 100:60 The epoxy grouting material is uniformly obtained.

Embodiment 3

[0026] Stir and mix 70 parts of epoxy resin E-44 and 26 parts of reactive diluent carbon dodecyl to tetradecyl glycidyl ether and 4 parts of interface modifier aluminate coupling agent to obtain component A; mix 35 parts Amine curing agent cycloaliphatic amine-593, 10 parts of water-resistant dispersant and 5 parts of accelerator 2,4,6-tris(dimethylaminomethyl)phenol were mixed evenly to obtain component B; component A and Component B is mixed uniformly according to the weight ratio of 100:50 to obtain epoxy grouting material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com