Fire and Sag Resistant Acoustical Panel and Substantially Clear Coating Therefor

a technology of acoustical ceiling panels and substantially clear coatings, which is applied in the field of enhanced fire rated and sag resistant acoustical ceiling panels, which can solve the problems of high flammability of natural fibers and the binder material which holds the fibers together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

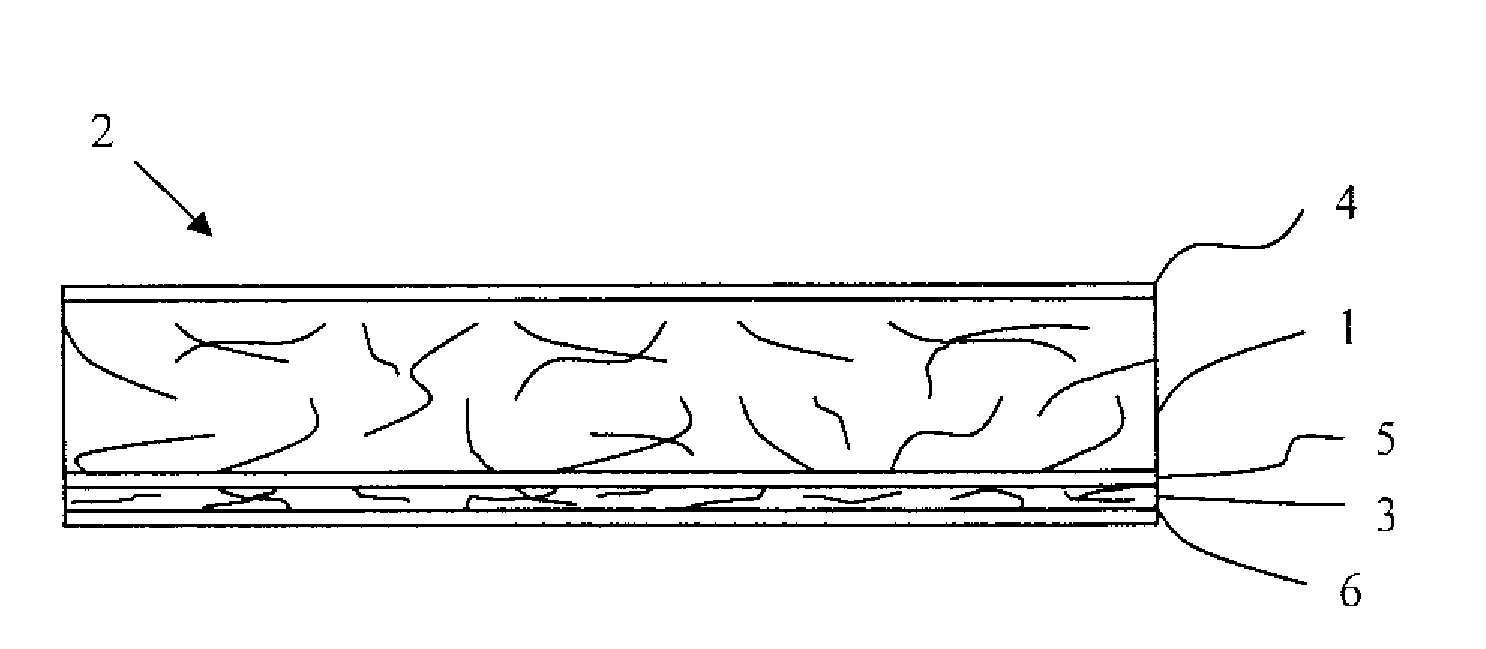

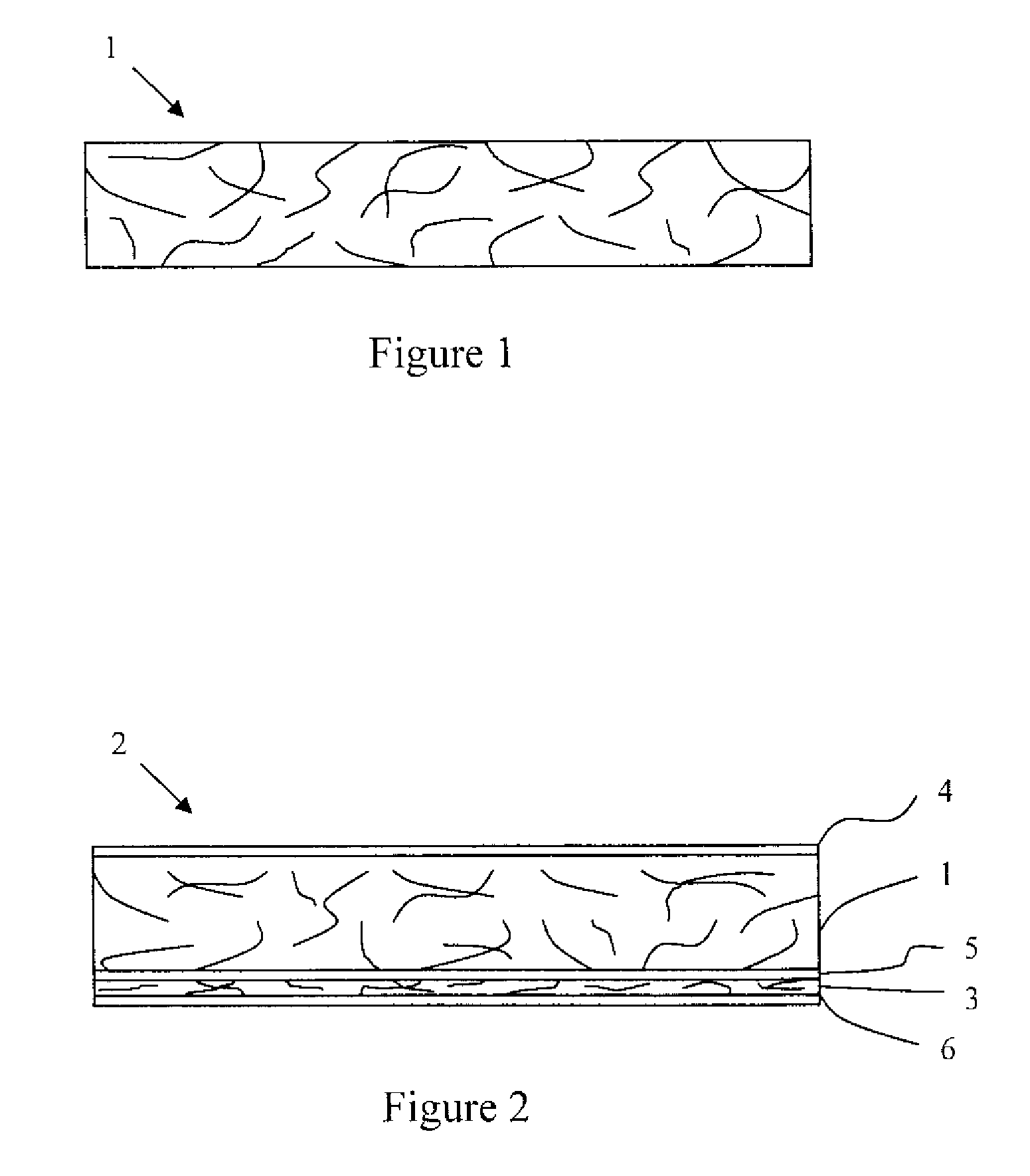

[0008]FIG. 1 shows a fire retardant mat 1 according to an embodiment of the invention. In order to form the fire retardant mat 1, a fiber component comprising natural fibers treated with the fire retardant is mixed with a binder to form a blend. The fiber component may be mixed with the binder, for example, by carding and co-mingling the fiber component with the binder in an air stream, which separates the natural fibers from one another and intimately blends the natural fibers with the binder. The blend, or furnish, is then deposited onto a foraminous wire and is compressed to a desired final thickness. Heat is then applied through the fiber web to either melt a thermoplastic binder or cure a thermosetting binder. Alternatively, the blend may be conveyed through an oven that blows heat through the mixture while the mixture is simultaneously being compressed with one or more wire screens.

[0009]As previously mentioned, the fiber component includes natural fibers treated with a fire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com