Test device for thermal properties and failure of cable under action of external radiation heat flows

A testing device and cable technology, applied in the field of cable heating behavior, radiation resistance characteristics and related cable fire safety, can solve the problems of single cable placement, scarce coupling effect of internal and external thermal effects, and can not fully reflect the complex layout of cables, etc. Achieve the effects of good reliability and repeatability, flexible and diverse layout methods, and accurate and controllable initial conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, but it is not intended to limit the present invention.

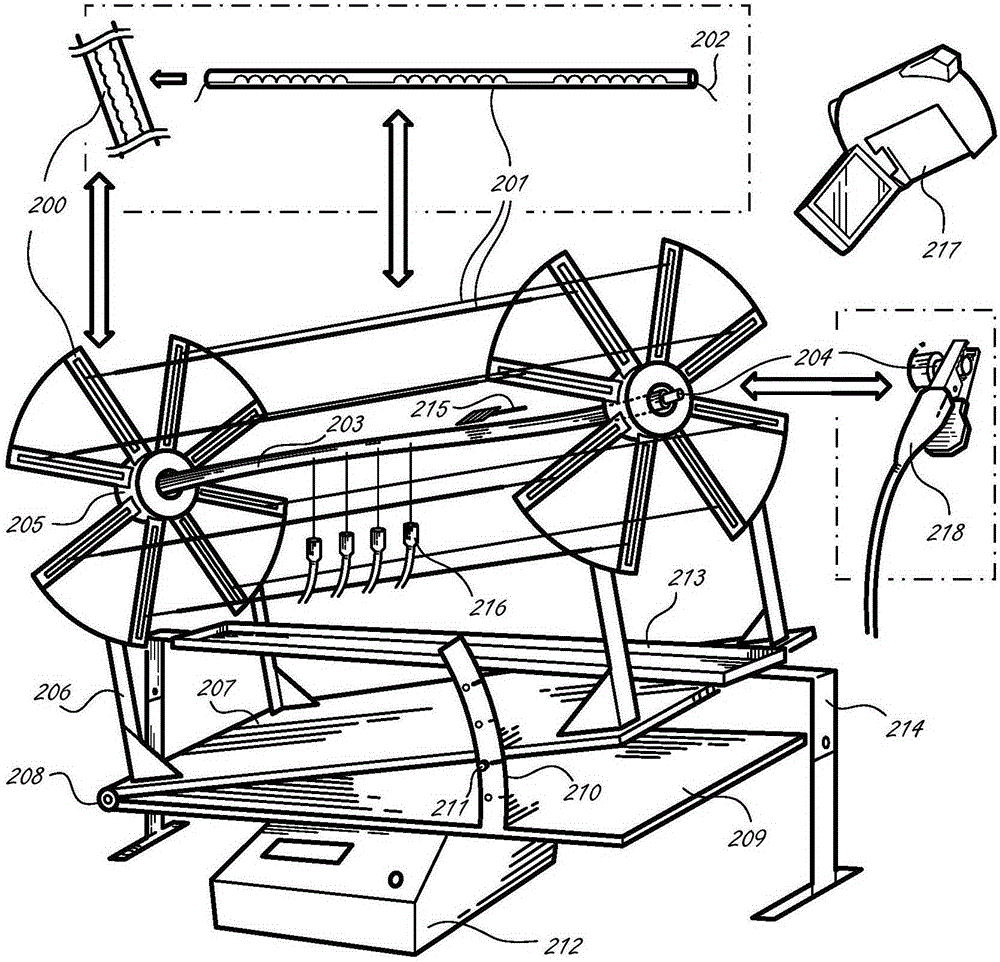

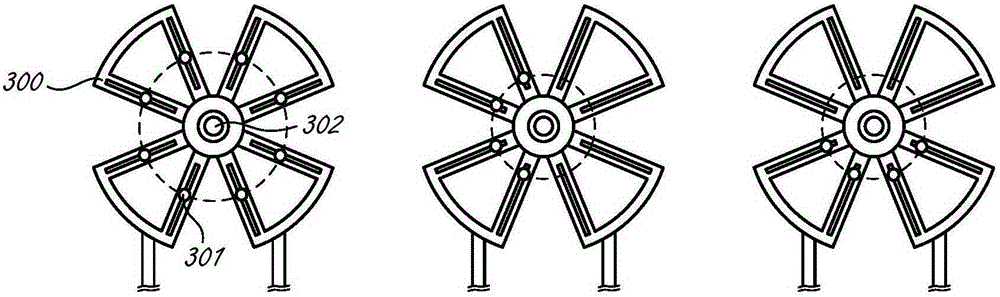

[0032] figure 1 A schematic top view of the structure of the cable heating characteristics and failure test device under the action of external radiant heat flow of the present invention is given, figure 2 It is a three-dimensional schematic diagram of the detailed structure of the cable test platform part in the test device, image 3 It is a schematic side view of various layout methods of the heating wire of the quartz tube of the external radiation source on the wheel-shaped metal fixed piece.

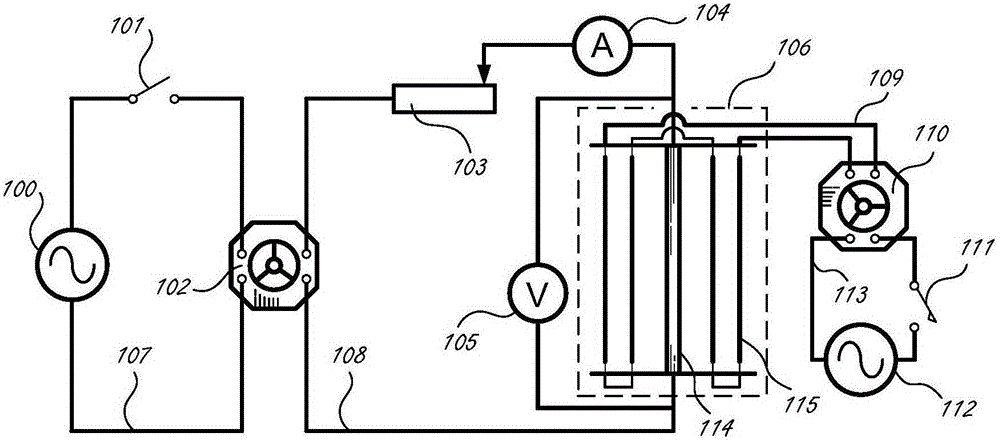

[0033] Such as figure 1 As shown, a 220V commercial AC power source 100 is connected in series to the input end of the first voltage regulator 102 through a switch 101 and a corresponding input circuit 107 of the first voltage regulator. The output terminal of the first voltage regulator 102 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com