Making method of fire-retardant heat insulation EPS board

A production method and technology of fireproof board, which are used in flat products, lighting and heating equipment, applications, etc., can solve the problems of low flame retardant performance, self-extinguishing from fire, insolubility, etc., to improve flame retardant performance and prevent the spread of flames , the effect of improving the oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

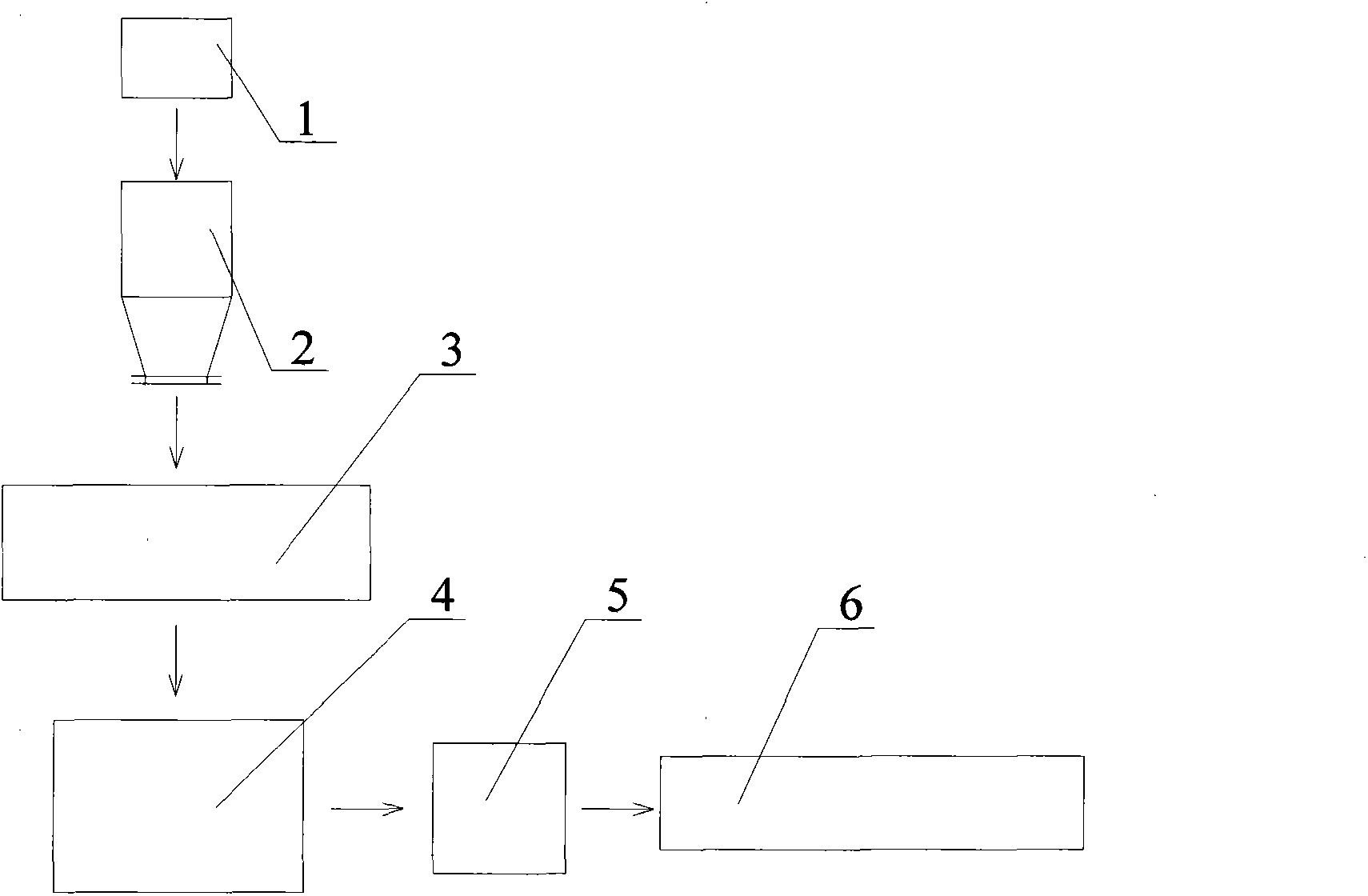

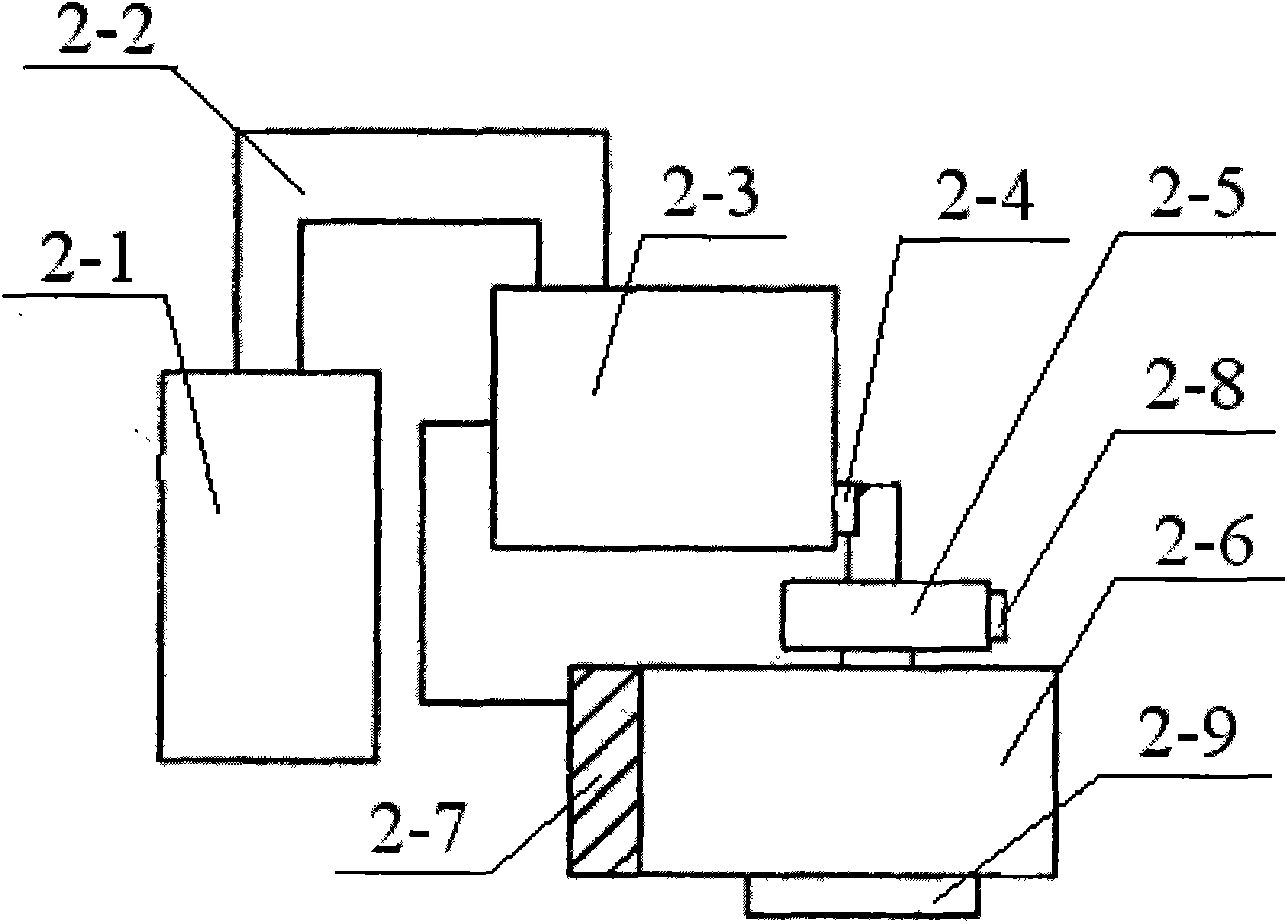

[0013] A method for manufacturing an EPS thermal insulation board, comprising foaming raw materials in a foaming machine 2 to prepare foam particles, heating, compressing, and forming the foam particles into a plate shape in a board forming machine 4, drying and cutting The process, the key is: the method also includes a film covering process. After the foam particles are produced by the foam machine 2, the outer surface of the foam particles is covered with a layer of fireproof film layer, and then put into the board forming machine 4 In the plate making.

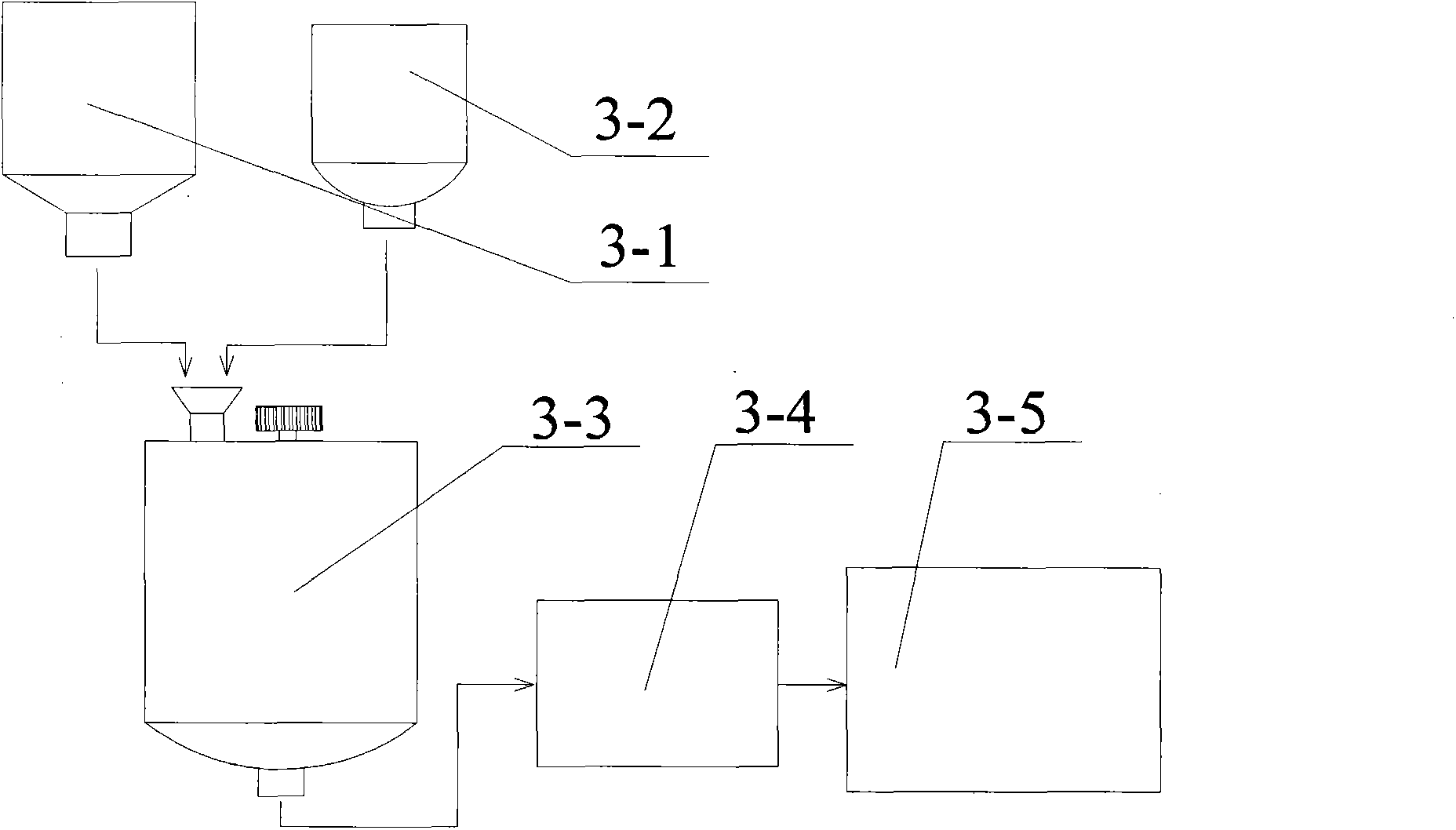

[0014] The film covering process is realized by means of the film covering system 3, and the film covering system 3 is arranged between the discharge port of the foaming machine 2 and the feed port of the board forming machine 4, including a metering bin 3-1, a raw material glue Stirring tank 3-2, mixing device 3-3, drying device 3-4 and screening device 3-5, the silo inlet of metering silo 3-1 is connected with the outlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com