Hydroxyapatite overlength nanowire flameproof paper with waterproof function

A technology of hydroxyapatite and nanowires, which is applied in the direction of fireproofing agent addition, papermaking, paper, etc., can solve the problem that fireproof paper does not have super-hydrophobic function, and achieve good application prospects, good thermal stability, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the invention is simple, the raw materials are easy to obtain, and the operation is convenient, and it is expected to realize batch preparation. The preparation method of the hydroxyapatite ultra-long nanowire fire-resistant paper with waterproof function provided by the present invention is exemplarily described below.

[0037]Preparation of hydroxyapatite ultralong nanowires. The hydroxyapatite ultra-long nanowires of the present invention can be prepared by solvothermal method, and can be prepared by referring to literature and patent reports: Zhu Yingjie, Lu Bingqiang, Chen Feng, High flexibility, high temperature and non-combustible hydroxyapatite Paper and its preparation method, patent number ZL201310687363.2; Ying-Ying Jiang, Ying-Jie Zhu, Feng Chen, Jin Wu, Ceramics International, 41, 6098-6102 (2015); Yong-Gang Zhang, Ying-Jie Zhu Feng Chen, Jin Wu, Materials Letters, 144, 135-137 (2015); other suitable preparation methods can also b...

Embodiment 1

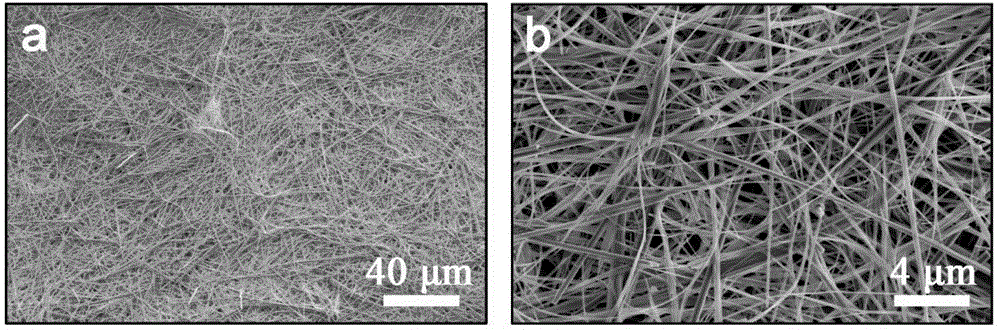

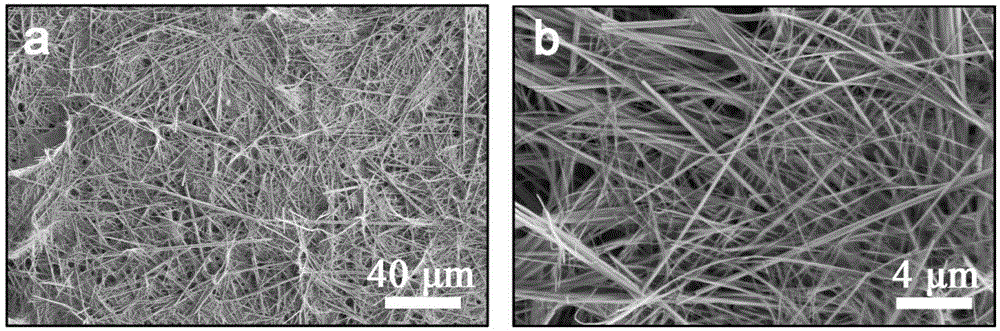

[0059] Stir 12.000 grams of ethanol and 12.000 grams of oleic acid evenly, add 20 milliliters of an aqueous solution containing 0.220 grams of calcium chloride, and after stirring well, add 20 milliliters of an aqueous solution containing 1.000 grams of sodium hydroxide and 10 milliliters of aqueous solutions containing 0.280 grams of phosphoric acid dihydrate dihydrate Aqueous solution of sodium hydrogen. The resulting mixture was transferred to a reaction kettle, sealed, heated to 180° C., and kept at this temperature for 24 hours. The obtained product is washed several times with ethanol and water respectively to obtain the superlong nanowire of hydroxyapatite. Disperse 100 mg of hydroxyapatite ultra-long nanowires in 50 ml of water, pour it into a sand core funnel for vacuum filtration, and dry at 60°C for 12 hours to obtain hydrophilic hydroxyapatite ultra-long nanowire fire-resistant paper, which is fire-resistant The water contact angle of paper is about 0°.

Embodiment 2

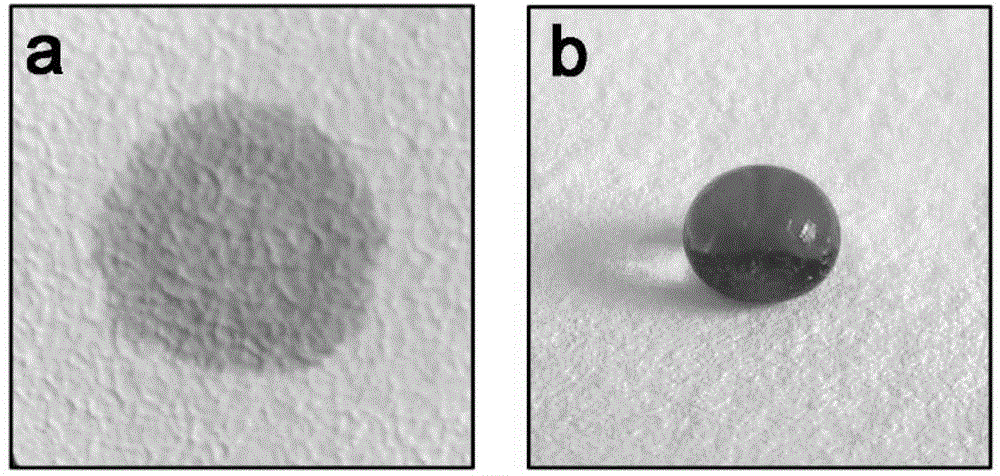

[0061] Stir 12.000 grams of ethanol and 12.000 grams of oleic acid evenly, add 20 milliliters of an aqueous solution containing 0.220 grams of calcium chloride, and after stirring well, add 20 milliliters of an aqueous solution containing 1.000 grams of sodium hydroxide and 10 milliliters of aqueous solutions containing 0.280 grams of phosphoric acid dihydrate dihydrate Aqueous solution of sodium hydrogen. The resulting mixture was transferred to a reaction kettle, sealed, heated to 180° C., and kept at this temperature for 24 hours. The obtained product is washed several times with ethanol and water respectively to obtain the superlong nanowire of hydroxyapatite. Soak 100 mg of hydroxyapatite ultra-long nanowires in 0.02 mol / L sodium oleate aqueous solution, pour it into a sand core funnel for vacuum filtration after 1 hour, and dry at 60°C for 12 hours to obtain hydroxyapatite with waterproof function Stone ultra-long nanowire fire-resistant paper, the water contact angle o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com