Method for preparing zinc oxide nanopillar array

A zinc oxide nano- and nano-column array technology, which is applied in the field of nano-materials, can solve the problems of poor array order and uneven size of zinc oxide nano-column arrays, and achieve the effects of improving order, easy promotion, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

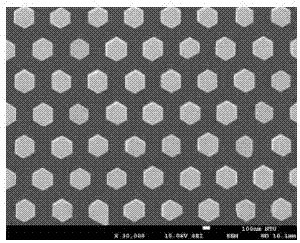

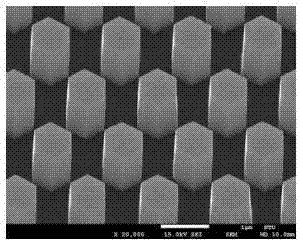

Image

Examples

Embodiment 1

[0022] 1. Deposit a Si3N4 film with a thickness of 40 nm on GaN by plasma enhanced chemical vapor deposition (PECVD), and then use nanoimprint lithography to make nano-array patterns, and use reactive ion etching technology to etch Si3N4 to prepare GaN templates with nanoarray patterns were obtained. The prepared GaN template was immersed in dilute hydrochloric acid (4%) solution, and cleaned in an ultrasonic cleaner for 10 minutes; rapid thermal annealing was performed at 700°C for 10 minutes under a nitrogen atmosphere (to remove residual organic matter on the surface of the GaN template); the annealed GaN The template was immersed in dilute hydrochloric acid (4%) solution again, and cleaned in an ultrasonic cleaner for 10 minutes; the GaN template was cleaned with deionized water, and finally dried with nitrogen for later use.

[0023] 2. Prepare Zn(NO3)2 and hexamethylphosphate triamide solution (hexamethylenetetramine, referred to as HMTA), put the prepared solution in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com