Method for simultaneously preparing hexamethylphosphoric triamide and dimethylamine hydrochloride

A technology of hexamethylphosphoric triamide and dimethylamine hydrochloride, applied in the chemical industry, can solve the problems of poor separation of the two salts, excess, environmental pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

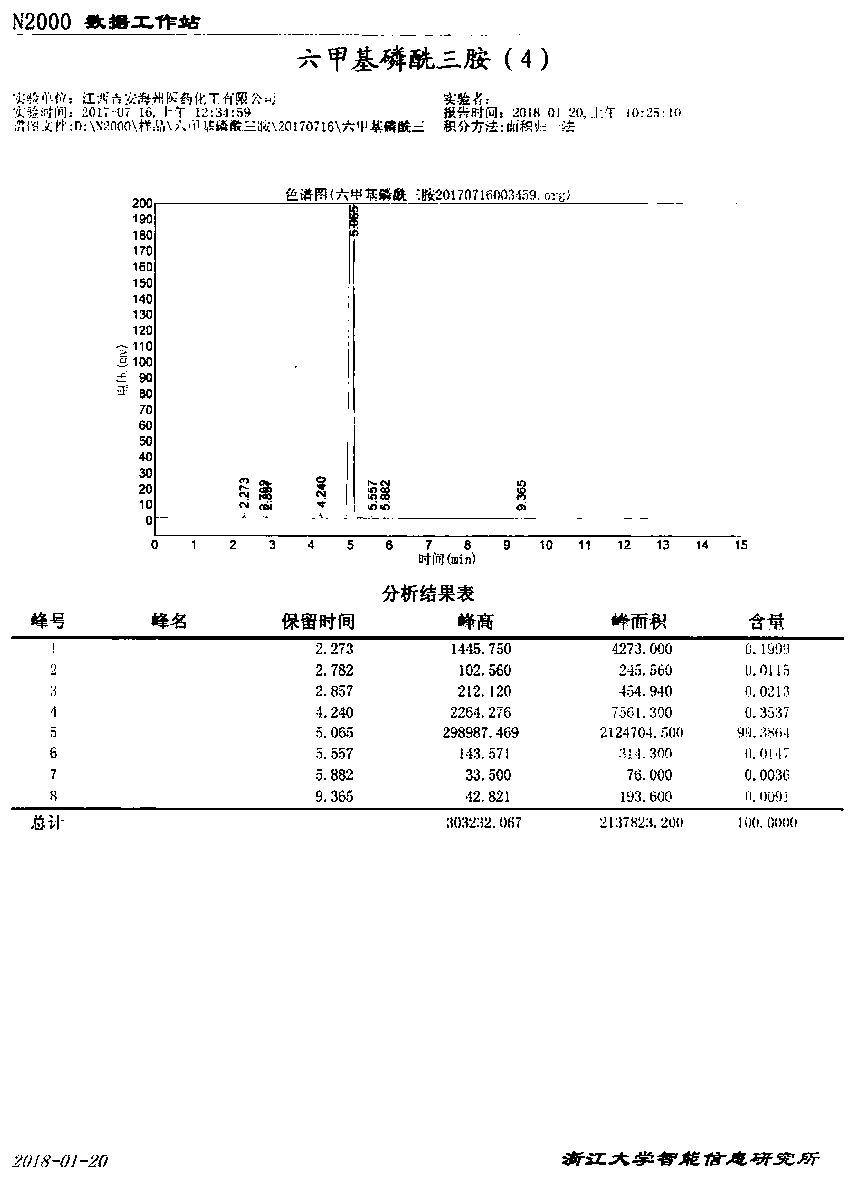

Embodiment 1

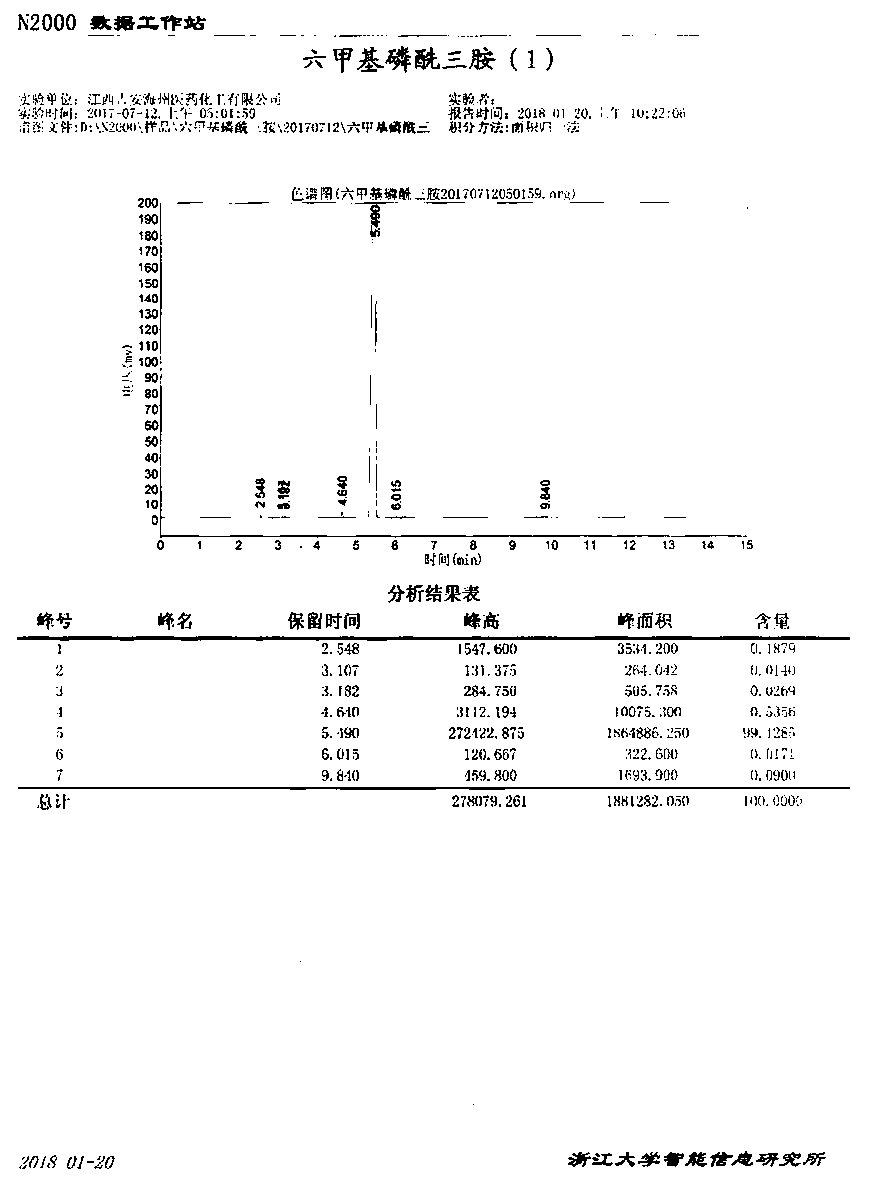

[0020] Add 200g of phosphorus oxychloride and 1100ml of xylene into the reaction flask, stir, control the temperature at 25-35°C and feed dimethylamine gas, a large amount of solids are produced, after feeding 360g of dimethylamine, raise the temperature to 55- 60°C, heat preservation reaction for 1 hour. Filter and separate to obtain the filter residue and filtrate; the filter residue is washed twice with 250ml xylene, and the washed solid is dried to obtain 298g dimethylamine hydrochloride with a titration content of 99.1wt%; after the filtrate is distilled to recover xylene, rectification obtains 226g hexamethylphosphoric triamide, content 99.4 wt %, yield 96.7%.

Embodiment 2

[0022] Add 200g of phosphorus oxychloride and 1100ml of xylene into the reaction bottle, stir, control the temperature at 35-45°C and feed dimethylamine gas, a large amount of solids are produced, after feeding 360g of dimethylamine, raise the temperature to 60- 65°C, heat preservation reaction for 1 hour. Filter and separate to obtain the filter residue and filtrate; the filter residue is washed twice with 250ml xylene, and the washed solid is dried to obtain 299g dimethylamine hydrochloride with a titer content of 99.2 wt %; after the filtrate is distilled and recovered xylene, rectification obtains 228g hexamethylphosphoric triamide, content 99.3 wt %, yield 97.5%.

Embodiment 3

[0024] Add 200g of phosphorus oxychloride and 1100ml of xylene into the reaction flask, stir, and control the temperature at 40-50°C to feed dimethylamine gas, a large amount of solids are produced, after feeding 360g of dimethylamine, raise the temperature to 62 -68°C, keep warm for 1 hour. Filter and separate to obtain the filter residue and filtrate; the filter residue is washed twice with 250ml xylene, and the washed solid is dried to obtain 299g dimethylamine hydrochloride with a titer content of 99.4 wt %; after the filtrate is distilled and recovered xylene, rectification obtains 230g hexamethylphosphoric triamide, content 99.3 wt %, yield 98.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com