Method for preparing heterocyclic aramid solution

A heterocyclic aramid solution technology, which is applied in the field of preparation of heterocyclic aramid solution, can solve the problems of reducing fiber mechanical properties, fiber mechanical properties, and increasing costs, and achieves reduced corrosion, fewer holes and impurities, and better mechanical properties. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

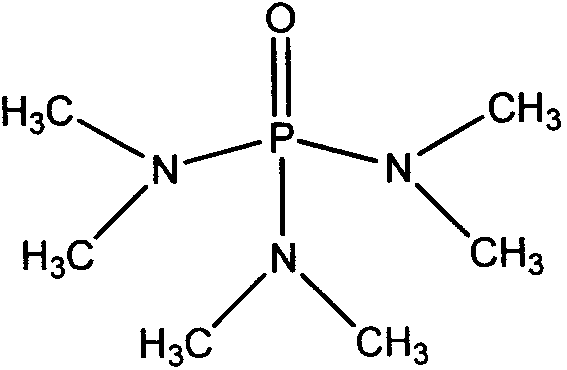

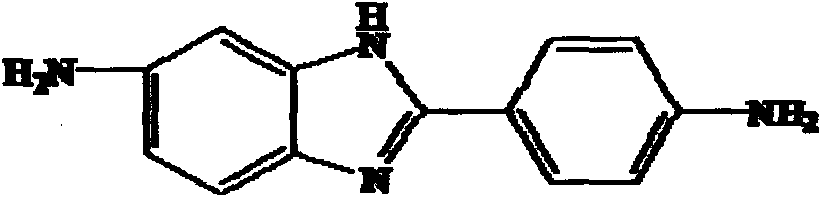

Method used

Image

Examples

Embodiment 1

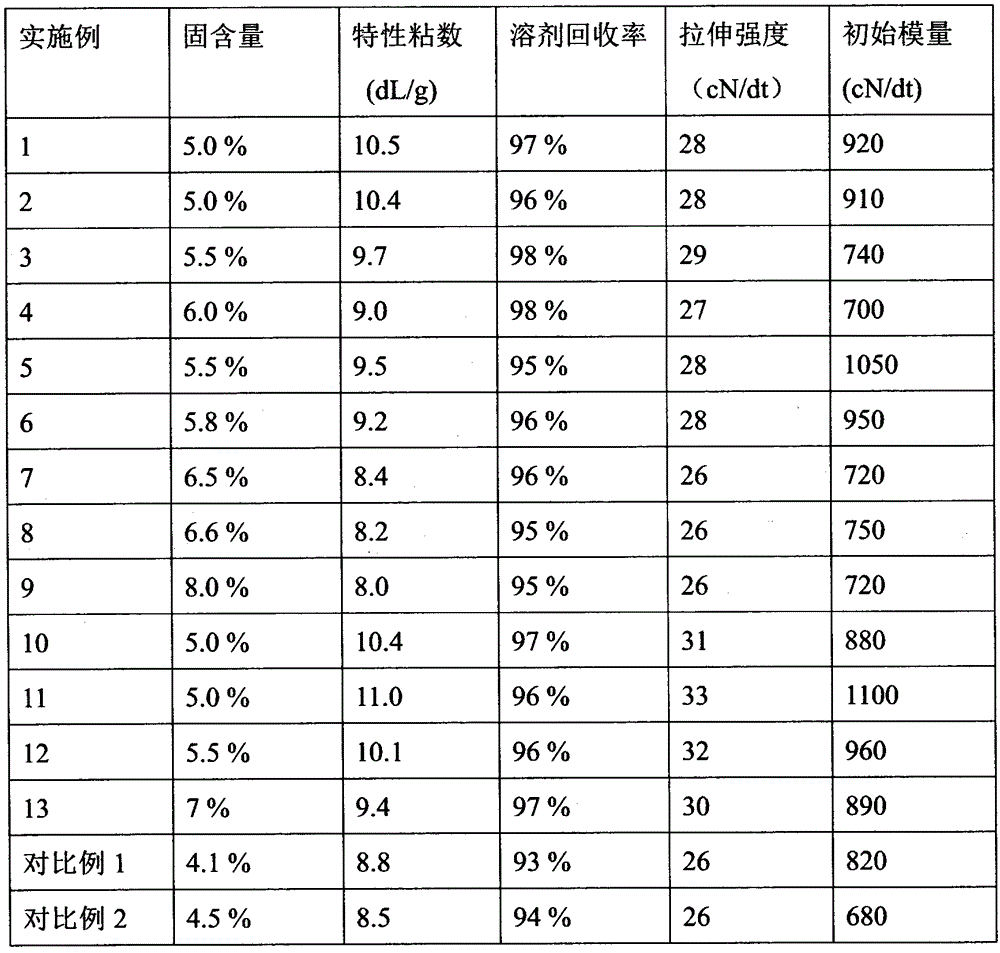

[0042] 160 grams of PABZ was added to 7.0 L of HMPA solvent, wherein the water content in the solvent was 300 ppm. Then 77.14 g of PDA was added, stirred under the protection of nitrogen until the diamine was dissolved, and then the temperature was lowered to 0°C. Then add 232 grams of TPC (80% of the total amount of TPC) to react for 20 minutes, then raise the reaction temperature to 30°C, then add the remaining TPC and stir for 1 hour to obtain a viscous heterocyclic aramid solution, wherein the ratio of mole fraction to TPC :PABZ:PDA=10:5:5, the solid content of heterocyclic aramid fiber is 5.0%.

[0043] The obtained heterocyclic aramid fiber solution is prepared by conventional wet spinning to prepare raw yarns, and static heat treatment is performed at 360° C. to obtain finished heterocyclic aramid fiber yarns. And carry out solvent recovery to the whole process, the solvent recovery rate is 97%. Ubbelohde viscometer was used to test the intrinsic viscosity of the hete...

Embodiment 2

[0045] The HMPA solvent recovered in Example 1 was subjected to polymerization again. 155.2 grams of PABZ was added to 6.79 L of recovered HMPA solvent, wherein the moisture content in the solvent was controlled to be 300 ppm. Then 74.82 g of PDA was added, stirred under the protection of nitrogen until the diamine was dissolved, and then the temperature was lowered to 0°C. Then add 225.04 grams of TPC (80% of the total amount of TPC) to react for 20 minutes, then raise the reaction temperature to 30°C, then add the remaining TPC and stir for 1 hour to obtain a viscous heterocyclic aramid solution, wherein the ratio of mole fraction TPC:PABZ:PDA=10:5:5, the solid content of heterocyclic aramid fiber is 5.0%.

[0046] The obtained heterocyclic aramid fiber solution is prepared by conventional wet spinning to prepare raw yarns, and static heat treatment is performed at 360° C. to obtain finished heterocyclic aramid fiber yarns. And carry out solvent recovery to the whole proce...

Embodiment 3

[0048] Polymerization was carried out according to the method of Example 1, wherein TPC:PABZ:PDA=10:7:3, the solid content of the heterocyclic aramid fiber was 5.5%, and the moisture content in the solvent HMPA was 200ppm. Under the protection of argon, two diamines, PABZ and PDA, were first added to the solvent HMDA. After the diamines were dissolved, the temperature was lowered to -10°C. Then add 90% TPC and react for 30 minutes, then raise the reaction temperature to 20°C, then add the rest of TPC and stir for 0.5h to get a viscous heterocyclic aramid solution.

[0049] The obtained heterocyclic aramid fiber solution was prepared by conventional wet spinning to prepare raw yarns, and static heat treatment was performed at 380° C. to obtain finished heterocyclic aramid fiber yarns. And carry out solvent recovery to the whole process, the solvent recovery rate is 98%. Ubbelohde viscometer was used to test the intrinsic viscosity of the heterocyclic aramid fiber, and the resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com