Eye-protective automobile adhesive film and preparation method thereof

A car film and coating technology, which is applied in the direction of coating, polyester coating, polyurea/polyurethane coating, etc., can solve problems such as permanent vision loss, less attention to car film, macular degeneration of the eyes, etc., and achieve improved heat insulation Resistance, improved absorption and shielding, damage reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

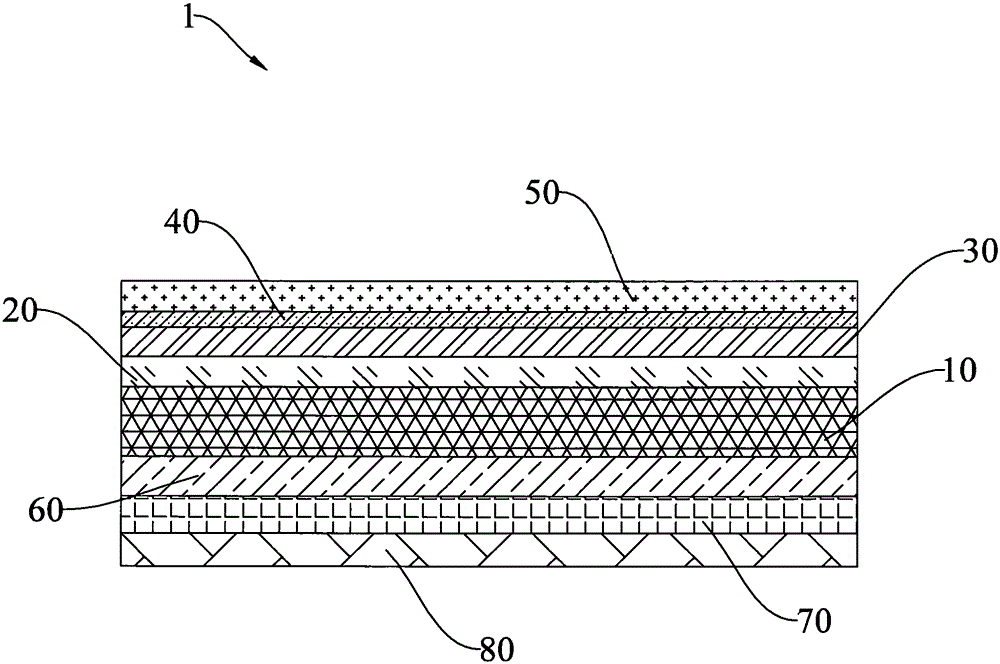

[0062] A method for preparing an eye-protecting automobile film 1 includes the steps:

[0063] S100 provides a release base layer 10, wherein the release base layer 10 is mainly composed of trifluoropropyl methyl cyclotrisiloxane, polytrimethylene terephthalate, methacryloxysilane, carboxymethyl Composition of cellulose and vinyl phenyl silicone oil;

[0064] In S200, an aqueous polyurethane solution containing nano titanium dioxide and tin antimony oxide is coated on the outer surface of the release base layer 10 to form a heat insulation layer 20;

[0065] In S300, an anti-ultraviolet mixture containing nano-cerium oxide is coated on the surface of the heat-insulating layer 20 to form an anti-ultraviolet layer, wherein the anti-ultraviolet layer is mainly composed of polytrimethylene terephthalate, polyimide, ethylene It is composed of triisoacryloxysilane, cyanoacrylate and nano-cerium oxide;

[0066] In S400, the acrylic adhesive mixture containing nano cobalt oxide is coated on ...

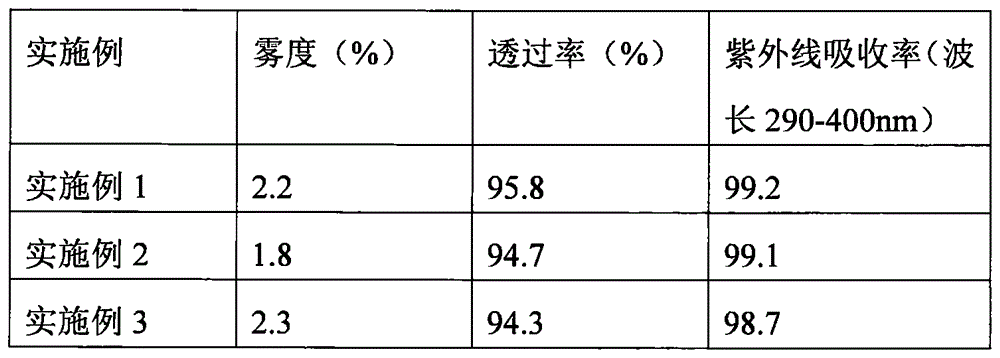

Embodiment 1

[0085] According to the preparation method of the eye protection car film, the material composition of the anti-ultraviolet layer by weight is: 10 parts polytrimethylene terephthalate, 30 parts polyimide, and 10 parts vinyl triisopropylene Oxysilane, 3 parts of cyanoacrylate, 6 parts of nano ceria, 8 parts of plasticizer, and 3 parts of antioxidant.

[0086] The material composition of the anti-blue light layer 60 is calculated in parts by weight: 100 parts acrylic adhesive, 6 parts acetylacetone, 8 parts nano-cobalt oxide, 8 parts o-phenylenediamine, 2 parts benzoyl peroxide, 3 parts Parts hexamethylphosphoric triamide and 0.5 parts isocyanate curing agent.

[0087] The step S200 further includes the steps:

[0088] Under magnetic stirring, add 5 parts of nano-titanium dioxide and 7 parts of tin antimony oxide to 60 parts of waterborne polyurethane;

[0089] Add 0.5 part of wetting agent, 0.5 part of thickener, 0.5 part of dispersant, and 0.5 part of film-forming auxiliary in sequen...

Embodiment 2

[0095] According to the preparation method of the eye protection car film, the material composition of the anti-ultraviolet layer by weight is: 15 parts polytrimethylene terephthalate, 40 parts polyimide, 8 parts vinyl triisopropylene Oxysilane, 4 parts of cyanoacrylate, 7 parts of nano-cerium oxide, 6 parts of plasticizer, and 2 parts of antioxidant.

[0096] The material composition of the anti-blue light layer 60 is calculated in parts by weight: 110 parts acrylic adhesive, 5 parts acetylacetone, 6 parts nano cobalt oxide, 6 parts o-phenylenediamine, 3 parts benzoyl peroxide, 2 parts Part hexamethylphosphoric triamide and 1 part isocyanate curing agent.

[0097] The step S200 further includes the steps:

[0098] Under magnetic stirring, add 7 parts of nano-titanium dioxide and 10 parts of tin antimony oxide to 70 parts of waterborne polyurethane;

[0099] Add 1 part of wetting agent, 1 part of thickener, 1 part of dispersant, 1 part of film-forming auxiliary in sequence, and adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com