Walnut shelling and picking device

A technology for shelling and walnuts, which is applied in the field of walnut shelling and kernel extraction devices, can solve the problems of low automation, poor adaptability of walnuts, and low performance indicators, so as to save labor, improve shelling rate and high kernel rate, and reduce processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

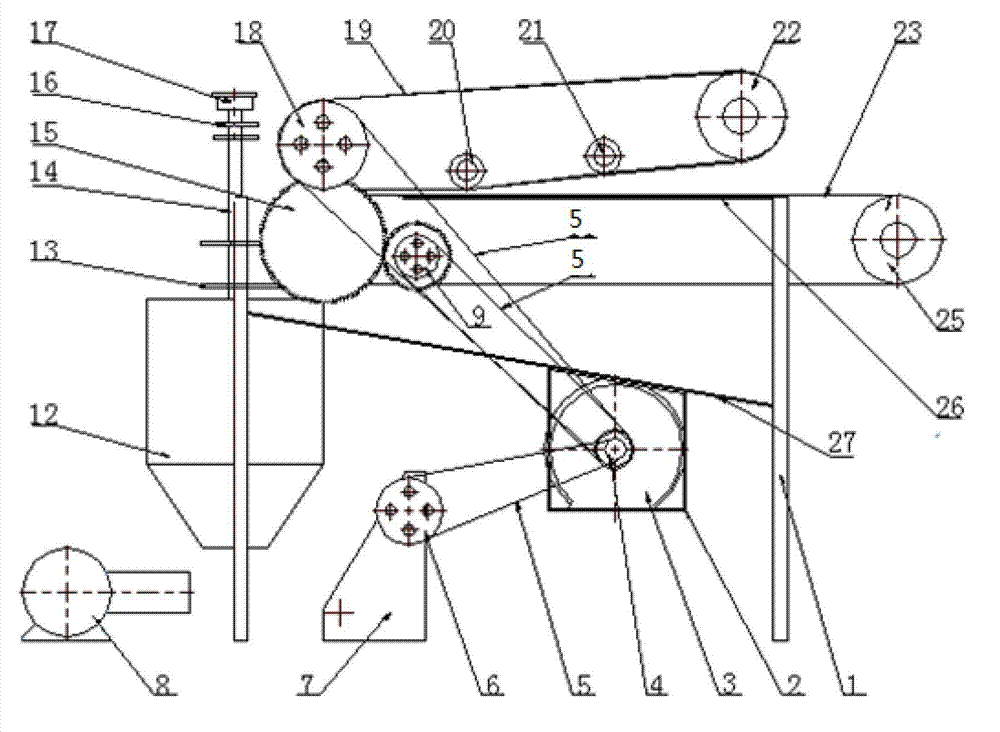

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0048] The general idea of the present invention is to realize high-efficiency shelling of walnuts and separation of shells and kernels. The driving shaft sleeve connected to the upper belt and the two supporting rollers have a height adjustment device, so that the gap between the two belts can be adjusted. The upper supporting roller sleeve 21 The horizontal distance from the lower idler sleeve 20 is a fixed value L, and the vertical distance is an adjustable value H, so as to effectively adjust the belt spacing and wedge angle when processing different varieties of walnuts, so as to form a steeper wedge gap. There is a parallel gap between the lower roller sleeve 20 and the lower working flat belt drive shaft sleeve 52 at the exit. The separation device performs three-stage separation treatment on the shell kernel.

[0049] Introduce a kind of embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com