Airtightness test device and method for combustion chamber nozzle

An air tightness test and combustion chamber technology, which is applied in the direction of measuring the acceleration and deceleration rate of the fluid and using the liquid/vacuum degree for liquid tightness measurement, etc. The effect of avoiding dislocation and deformation, reducing labor intensity and shortening labor time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with embodiment.

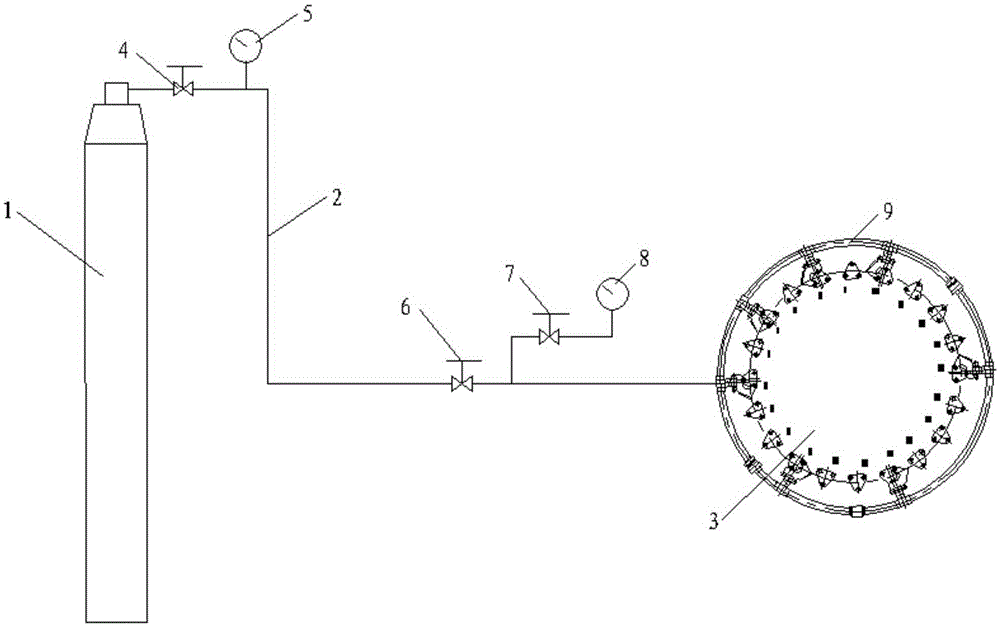

[0022] according to figure 1 As shown, an airtight test device for a combustion chamber nozzle includes a gas storage bottle 1, the gas storage bottle 1 is connected to the fuel main pipe of the main combustion chamber 3 through a pipeline 2, and the gas storage bottle 1 and the fuel oil main pipe 9 are connected sequentially on the pipeline A total pressure valve 4, a total pressure gauge 5 and a constant pressure valve 6 are arranged in series, and a pressure gauge valve 7 and a sealed pressure gauge 8 are arranged in parallel on the pipeline connecting the constant pressure valve 6 and the fuel main pipe 9.

[0023] Filled in the gas cylinder 1 is nitrogen.

[0024] The method for carrying out the airtight test of the combustion chamber nozzle by using the airtight test device of the above-mentioned combustion chamber nozzle, the specific steps are as follows:

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com