Photoelectric fructus jujubae grading production line

A production line and jujube technology, which is applied in the field of jujube photoelectric grading production line, can solve the problems that affect the working efficiency of production and processing equipment, the jujube chips cannot be effectively filtered, and manual picking is required, so as to save labor time, improve production efficiency, and avoid The effect of human involvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

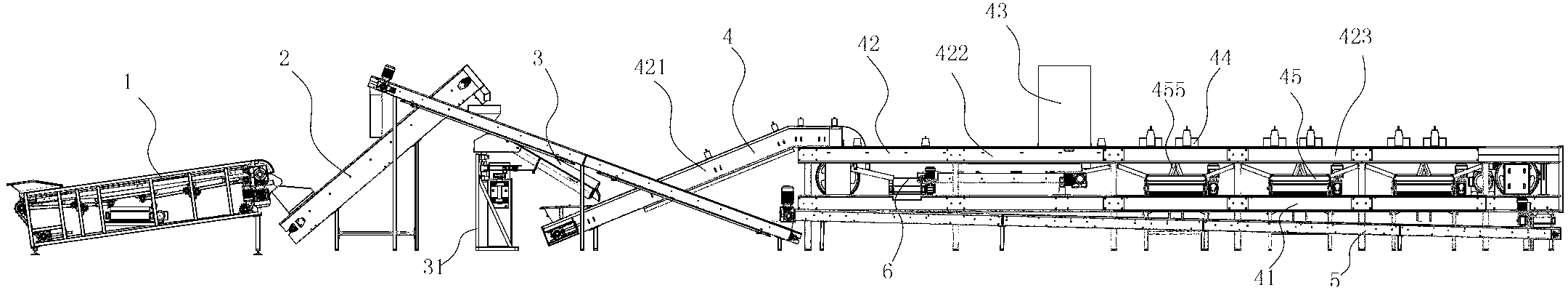

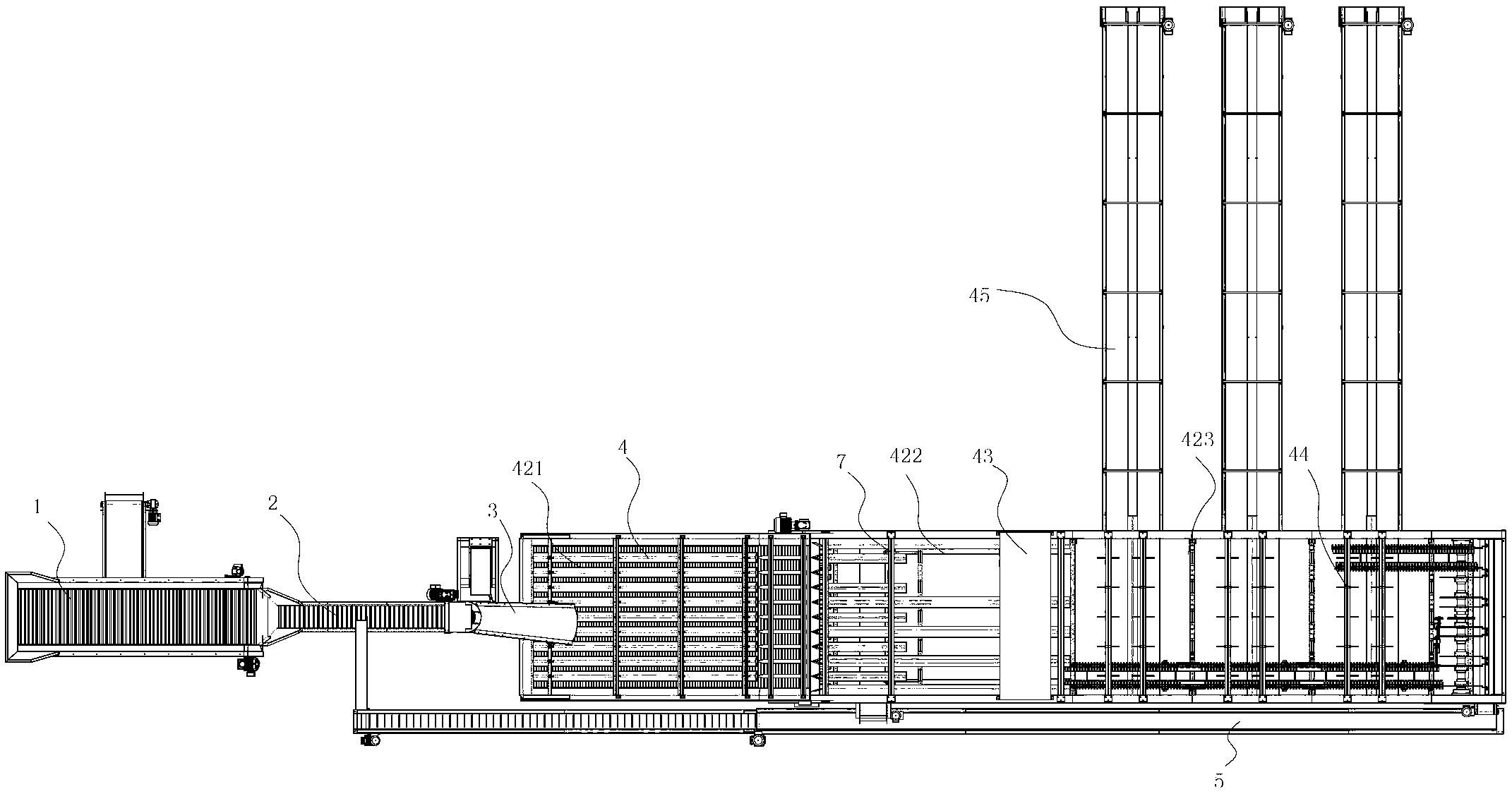

[0033] The present invention as Figure 1-13 As shown, it includes a roller pre-screening machine 1, a scraper feeder 2, a turtle shell distributor 3 and a sorting and conveying device 4 arranged in sequence;

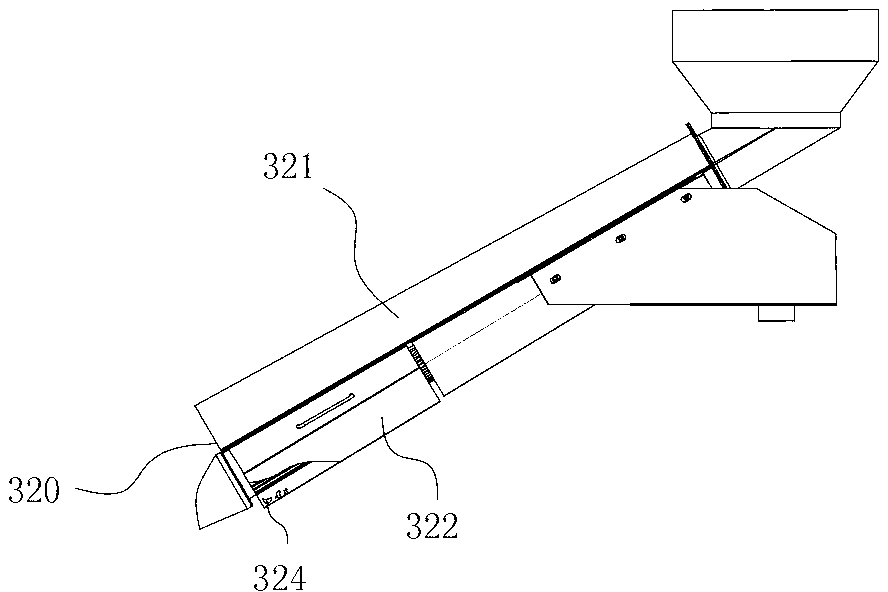

[0034] The scraper feeder 2 includes a pair of side plates, a conveyor belt and a scraper arranged on the conveyor belt. The side plates are fixed on both sides of the conveyor belt. The distance between the two ends of the scraper and the side plates is 15 -40mm, the setting of the scraper increases the jujube conveying capacity, improves work efficiency, and shortens the working time; at the same time, it avoids the phenomenon of jujube pinching.

[0035] The sorting conveying device 4 includes a frame 41, a grading conveying mechanism 42, an image detection mechanism 43, a grading executing mechanism 44, a control host and a grading discharging mechanism 45; the grading conveying mechanism 42 is arranged on the frame 41 , the grading conveying mechanism 42 sequentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com