Peel-pith-leaf separator of maize straw

A corn stalk and separator technology, applied in mechanical equipment, sugarcane machining and other directions, can solve the problems of separation mechanical vibration, difficult to cut off, high energy consumption, etc., and achieve the effect of increasing conveying friction and avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

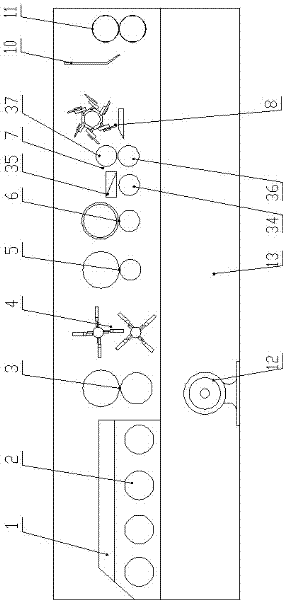

[0032] Such as figure 1 As shown, the corn stalk husk pulp leaf separator of the present invention comprises a frame 13 and a power mechanism 12 arranged on the frame, and the frame 13 is sequentially provided with guiding conveyors connected with the power mechanism 12 from front to back. mechanism, leaf removal mechanism, peeling mechanism and output mechanism.

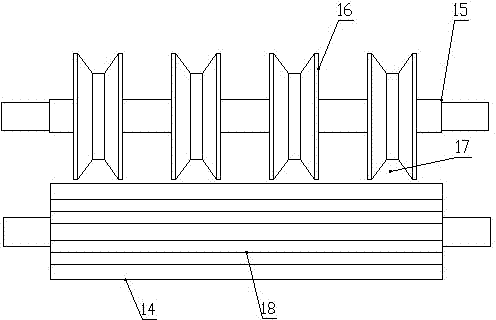

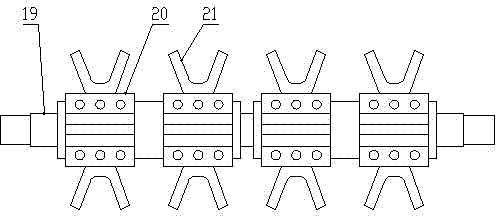

[0033] The guide conveying mechanism includes a guide frame 1 arranged in sequence from front to back, a conveying roller 2 arranged on a frame 13 and a feeding device 3, and the feeding device 3 includes a first idler roller 14 and a first idler roller 14 arranged in parallel. The upper feeding roller shaft 15 is provided with a feeding roller 16 having an annular wheel groove, and a straw feeding channel 17 is formed between the wheel groove of the feeding roller 16 and the upper surface of the first idler roller 14 . At least one feeding roller 16 is provided, and the surface of the first idler roller 14 is unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com