Tobacco material smoke generator for heat-not-burn tobacco products and preparation method and application of tobacco material smoke generator

A technology of tobacco materials and smoke-generating bodies, which is applied in the fields of tobacco, processed tobacco, and smoker's supplies, and can solve problems such as difficulty in ensuring the consistency of cigarettes, flexibility of cigarettes and easy damage, and poor stability of smoke volume, etc. Ease of use, strength, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the tobacco material smoking body includes a dry smoking body material and an atomizing agent.

[0038] Dry smoking body materials include tobacco powder, lignocellulose and binders. The mass ratio of tobacco powder, lignocellulose and binder is 1:8:1. The binder is squash gum. The lignocellulose is poplar birch powder, and its mesh number is not less than 50 mesh.

[0039] The atomizer includes essence and solvent, and the mass ratio of essence and solvent is 1:9. The atomizer is obtained by mixing the essence and the solvent. The solvent is propylene glycol.

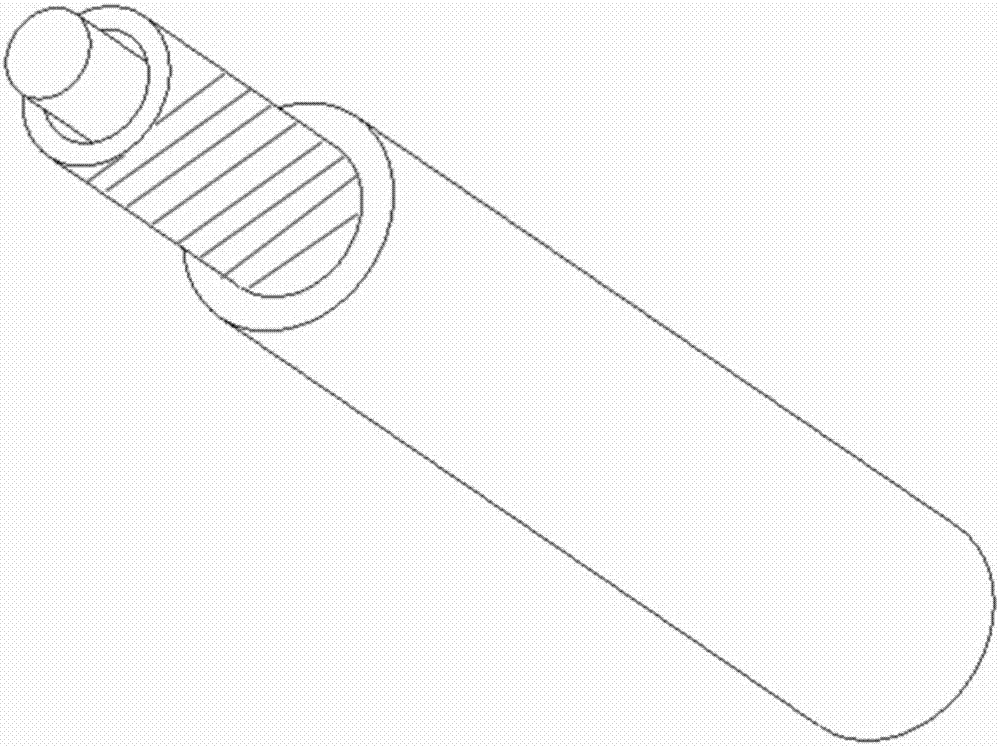

[0040] Mix tobacco powder, lignocellulose and safflower gum evenly at room temperature, or add a small amount of water; extrude into a solid round strip with an outer diameter of Φ7mm through a pressure molding machine; then dry, and the drying temperature is set to 90°C; after drying and solidification, cut it into 16mm solid mandrel sections; soak in the atomizing agent, and after unif...

Embodiment 2

[0044] In this embodiment, the tobacco material smoking body includes a dry smoking body material and an atomizing agent.

[0045] Dry smoking body materials include tobacco powder, lignocellulose and binders. The mass ratio of tobacco powder, lignocellulose and binder is 5:4:1. The binder is guar gum. The mesh number of the lignocellulose is not less than 50 mesh.

[0046] The atomizer includes essence and solvent, and the mass ratio of essence and solvent is 1:99. The atomizer is obtained by mixing the essence and the solvent. The solvent is glycerin.

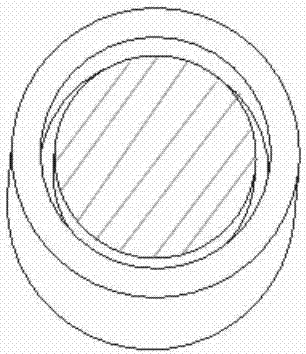

[0047]Mix tobacco powder, lignocellulose and guar gum evenly, and add a small amount of water; through a pressure molding machine, extrude into a hollow round bar shape, with an inner cavity of Φ5mm and an outer diameter of Φ7mm; drying, drying The temperature is 80° C.; after drying and solidification, it is cut into 16 mm cavity mandrel segments; soaked in an atomizing agent to obtain a smoking body of tobacco material...

Embodiment 3

[0051] In this embodiment, the tobacco material smoking body includes a dry smoking body material and an atomizing agent.

[0052] Dry smoking body materials include tobacco powder, lignocellulose and binders. The mass ratio of tobacco powder, lignocellulose and binder is 7:2:1. The binder is xanthan gum. The mesh number of the lignocellulose is not less than 80 mesh.

[0053] The atomizer includes essence and solvent, and the mass ratio of essence and solvent is 1:99. The atomizer is obtained by mixing the essence and the solvent. The solvent is a mixture of glycerin and propylene glycol, and the mixing ratio of the two is 1:1.

[0054] Mix tobacco powder, lignocellulose and xanthan gum evenly, and add a small amount of water; extrude it into a hollow round strip through a pressure molding machine, with an inner cavity of Φ5mm and an outer diameter of Φ7mm; drying, the drying temperature is 80°C; cut into 16mm cavity mandrel segments; soak in the atomizing agent to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com