Cigarette sets applied to heat-not-burn cigarettes

A heat-not-burn and cigarette technology, which is applied in the fields of applications, tobacco, and smoker supplies, can solve the problems of difficulty in adding a high proportion of smoker to the core material, large space for improving the richness of tobacco aroma, and low smoke release. Achieve the effects of increasing richness, solving the difficulty of adding, and increasing the amount of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

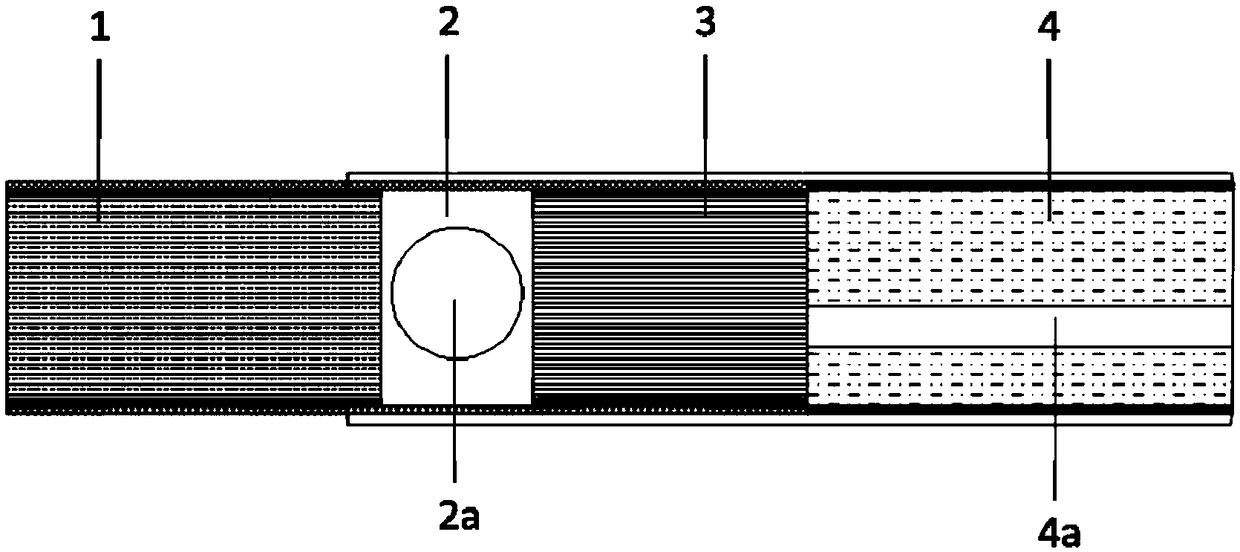

[0034] Such as figure 2 As shown, a pressure-exploded spherical supplementary material 2b is added to the hollow section 2, and the filling is a fuming agent that can stably release aerosols in the temperature range of 30-100°C. The cooling section 3 is made of polylactic acid material, and the mouthpiece Segment 4 is a solid cellulose acetate filter stick, and the middle of the solid cellulose acetate filter stick is added flavoring gel 4a, and the flavoring gel can be spherical, capsule-shaped or bar-shaped. When inhaling, pressure is used to explode the spherical supplementary material 2b, the filling can effectively supplement the amount of smoke in the smoke, and the aroma-enhancing gel 4a can supplement the aroma of the smoke and effectively improve the sensory quality. The sensory evaluation results are as follows:

[0035] Sample serial number

Embodiment 2

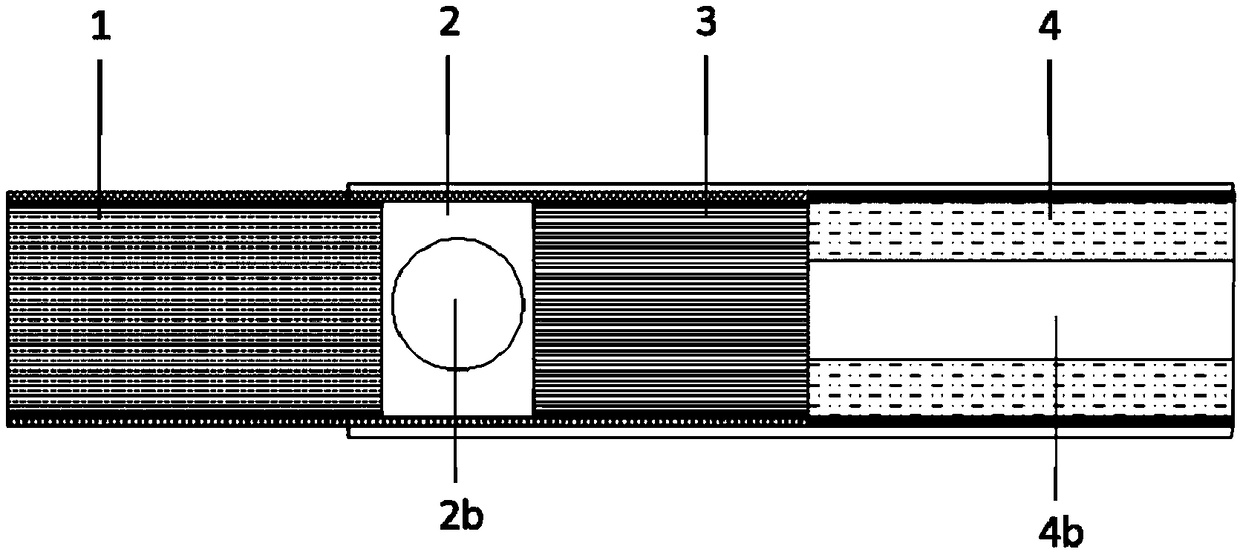

[0037] Such as image 3 Shown: a spherical supplementary material 2b is added to the hollow section 2 where the pressure passes through the flue gas temperature to melt the wrapping material and release the inner filler. The filler is capable of stably releasing the fragrance of the aerosol within the temperature range of 30-100°C material, the cooling section is made of metal-coated composite paper material, the nozzle section is a circular hollow acetate filter rod, and the diameter of the circular cavity 4b is 1-5mm. When smoking, the smoke passes through the hollow section, and the temperature of the smoke melts the wrapping material of the supplementary material to release the internal fragrance substance. The fragrance substance can effectively supplement the smoke aroma of the smoke, and the fragrance substance absorbs part of The heat can significantly reduce the flue gas temperature. The circular hollow cellulose acetate filter rod can effectively reduce adsorption a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com