Fragrance module formula, fragrance for heat-not-burn cigarette and preparation method of heat-not-burn cigarette

A heat-not-burn and flavoring technology, which is applied in the field of preparation of flavor module formulations, flavors and heat-not-burn cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

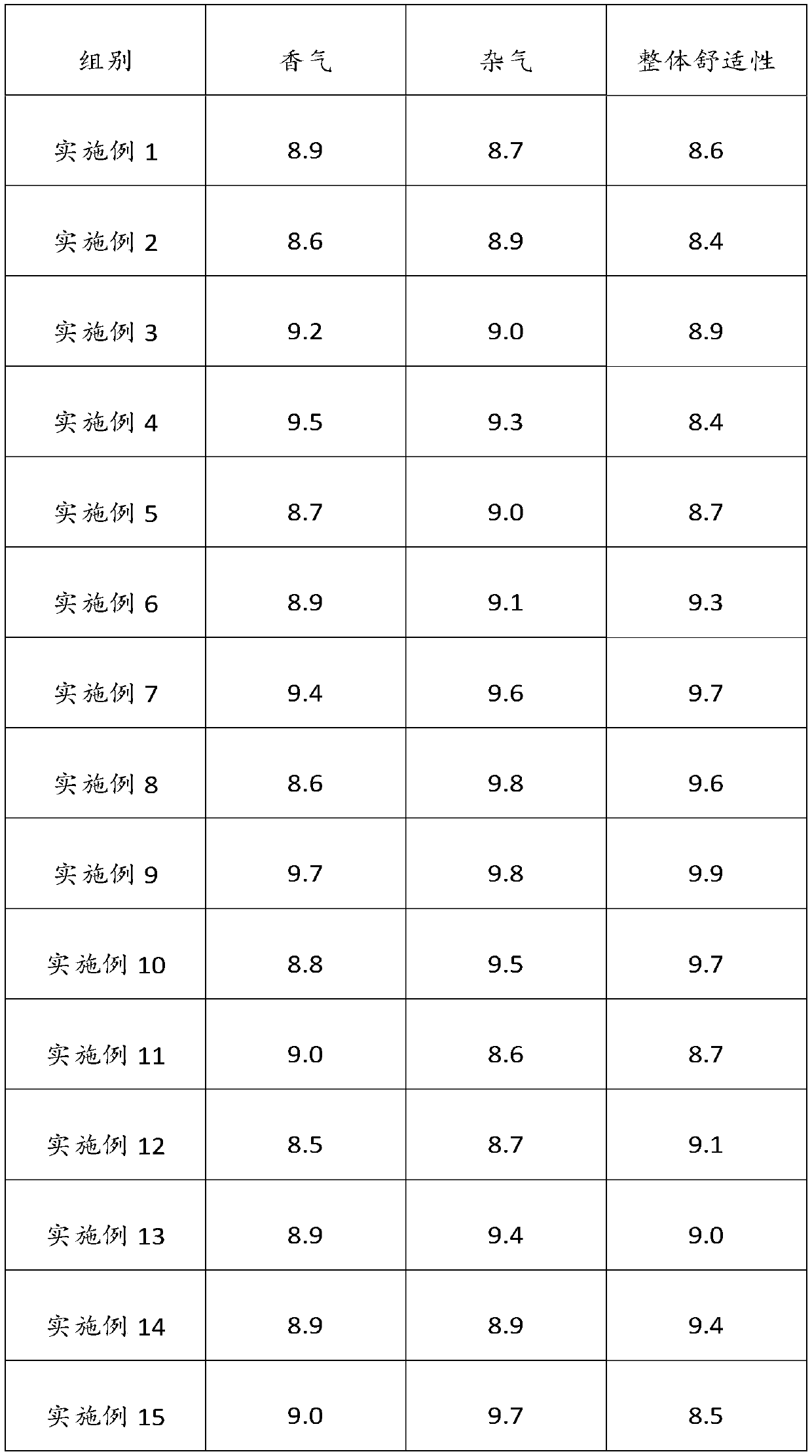

Examples

preparation example Construction

[0033] The embodiment of the present invention also provides a method for preparing a flavor used in heat-not-burn cigarettes, which includes the following steps: uniformly mixing the components in the flavor module formula above. Generally speaking, all the components in the fragrance formula are in liquid state and can be directly mixed evenly; when the components in the fragrance formula have solid and liquid states, they can be dissolved to form a liquid mixture after mixing, or they can not be completely dissolved to form a suspension , colloid, or prepared into granules or powders.

[0034]The embodiment of the present invention also provides a method for preparing a heat-not-burn cigarette, comprising loading the prepared flavor into the heat-not-burn cigarette. What needs to be added is that the spices prepared in the examples of the present invention can be loaded on tobacco or tobacco by spraying method, incense thread method (incense thread is not limited to cotton ...

Embodiment 1

[0039] This embodiment provides a fragrance module formula, in parts by weight, 10 parts of herbal main fragrance, 10 parts of solvent, 2 parts of tobacco extract, 0.5 part of flavoring agent, 0.1 part of flavoring agent and 0.1 part of stabilizer. Among them, the herbal main fragrance is licorice, the solvent is ethanol, water, propylene glycol (mass ratio is 3:5:2), the tobacco extract is American flue-cured tobacco extract, and the flavor enhancer is the same amount of citronellol, geraniol and hawthorn extract, the flavoring agent is the same amount of vanillin, furanone and jasmonal, and the stabilizer is the same amount of α-hydroxy acid and glycerin.

[0040] This embodiment also provides a method for preparing heat-not-burn cigarettes, which includes the following steps:

[0041] The components in the above formula are uniformly mixed to obtain the spice, and the spice is uniformly and stably added at 2% to the aroma-producing material of the heat-not-burn cigarette an...

Embodiment 2

[0043] This example provides a fragrance module formula, in parts by weight, 90 parts of herbal main fragrance, 90 parts of solvent, 50 parts of tobacco extract, 70 parts of flavoring agent, 50 parts of flavoring agent and 50 parts of stabilizer. Among them, the herbal main fragrance is mustard and angelica with a mass ratio of 1:3, the solvent is propylene glycol: water 2:8, the tobacco extract is Yunyan extract, and the flavor enhancer is equal amounts of strawberry extract, coffee tincture and nutmeg oil, the flavoring agent is an equal amount of isobutyraldehyde, citric acid and chicory extract, and the stabilizer is an equal amount of maltitol and xylitol.

[0044] This embodiment also provides a method for preparing heat-not-burn cigarettes, which includes the following steps:

[0045] Mix the components in the above formula evenly to obtain flavors, add the flavors evenly and stably at 4.5% to the aroma-producing material of the heat-not-burn cigarette and prepare it in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com