Cooling unit for holder of heat-not-burn fuming product and preparation method of cooling unit

A technology for heat-not-burn and smoking products, applied in the field of smoking products, can solve the problems of limited market promotion, poor smoking experience, smoke burning, etc., and achieve the effects of improving aesthetics, reducing burning, and reducing smoke temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

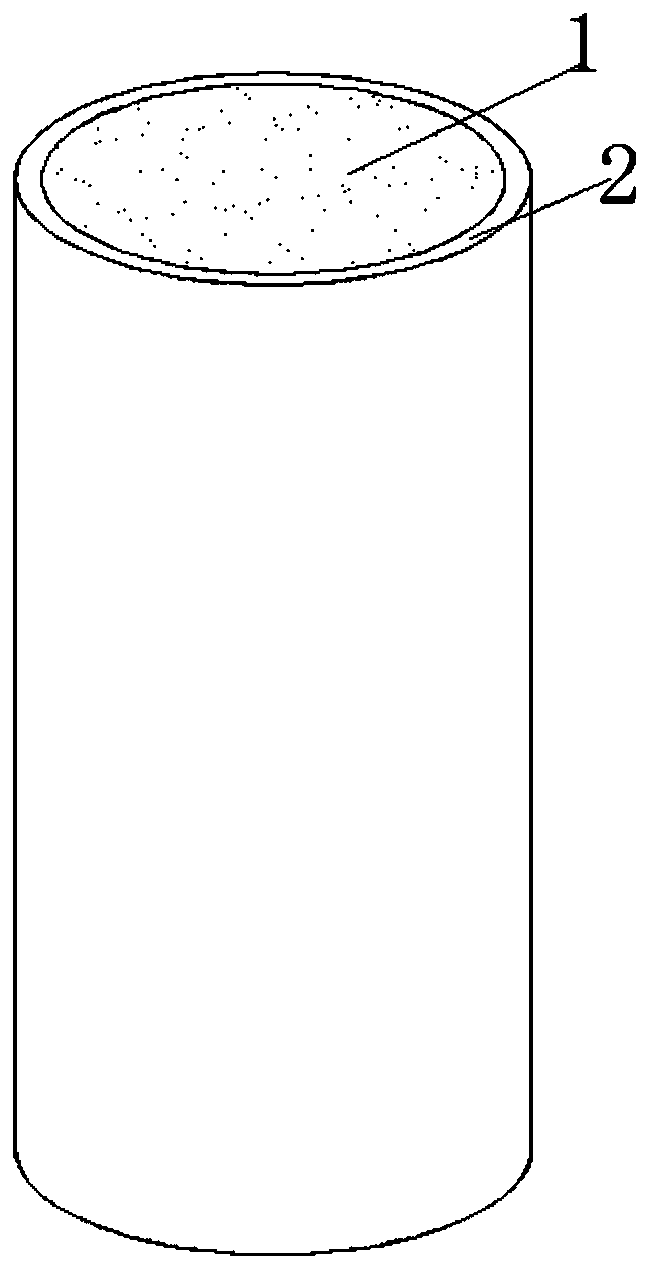

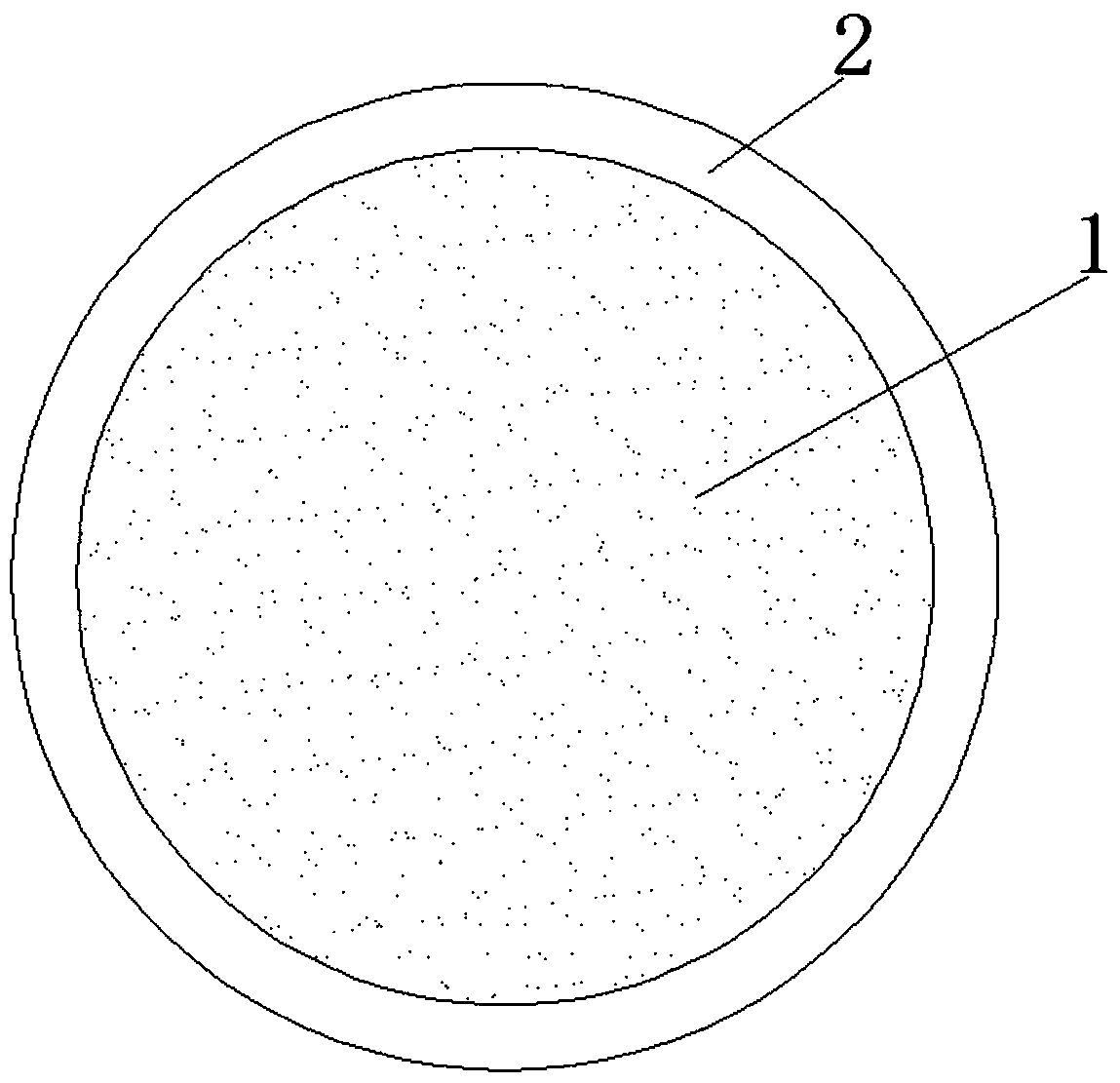

[0027] In embodiment 1, refer to Figure 1-2 , used to heat the cooling unit of the mouth rod of non-burning smoking products. The cooling unit is connected with the hollow section, and the filter section is connected with the cooling unit. The cooling unit includes a cooling inner core 1, and the cooling inner core 1 is cylindrical;

[0028] The material of the cooling inner core 1 is polylactic acid and a compound, and the compound includes one or more of polyethylene glycol, aluminum hydroxide, magnesium hydroxide, and nano silicon dioxide.

[0029] The compound accounts for 1-20% of the mass fraction of the cooling inner core 1 .

[0030] The outer side of the cooling inner core 1 is loaded with a heat absorbing material, and the heat absorbing material includes one or both of sodium sulfate decahydrate and sodium tetraborate decahydrate.

[0031] The heat-absorbing material accounts for 1-10% of the mass fraction of the cooling inner core 1 .

[0032] The outside of th...

Embodiment 2

[0038] In embodiment 2, repeat example 1, have following difference:

[0039] A method for preparing a cooling unit for heating a mouthpiece of a non-burning smoking product, comprising the following steps:

[0040] S1. After mixing polylactic acid with a mass fraction of 90% and aluminum hydroxide with a mass fraction of 10% in a high-speed mixer, add it to a twin-screw extruder for blending, extrusion, stranding, cooling and cutting Particles to obtain polylactic acid composite particles;

[0041] S2. Prepare the polylactic acid composite particles obtained in S1 into a spiral cylinder with a circumference of 23.5 mm and a length of 30 mm through a mold to obtain a polylactic acid composite cylinder;

[0042] S3. Immerse the polylactic acid composite cylinder obtained in S2 in a 10% aqueous solution of sodium tetraborate decahydrate for 2 hours, and obtain the cooling inner core 1 after drying.

Embodiment 3

[0043] In embodiment 3, repeat example 1, have following difference:

[0044] A method for preparing a cooling unit for heating a mouthpiece of a non-burning smoking product, comprising the following steps:

[0045] S1. The cooling unit is composed of polylactic acid with a mass fraction of 88% and magnesium hydroxide with a mass fraction of 12%. After mixing evenly in a high-speed mixer, add it to a twin-screw extruder for blending, extrusion, and drawing , cooling and dicing to obtain polylactic acid composite particles;

[0046] S2. Prepare the polylactic acid composite particles obtained in S1 through a mold into a cylinder with a circumference of 24.0 mm and a length of 30 mm. The interior is a net-like wavy cylinder to obtain a polylactic acid composite cylinder;

[0047] S3. Immerse the polylactic acid composite cylinder obtained in S2 in 15% sodium sulfate decahydrate aqueous solution for 1 hour, and obtain the cooling inner core 1 after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com