Microwave-heat-not-burn smoking set

A technology for microwave heating and smoking utensils, which is applied in the directions of tobacco, smoker's products, applications, etc., can solve the problems of long heating and preheating time, low heating efficiency, easy damage, etc., achieves simple conductor structure, prevents microwave leakage, and improves uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

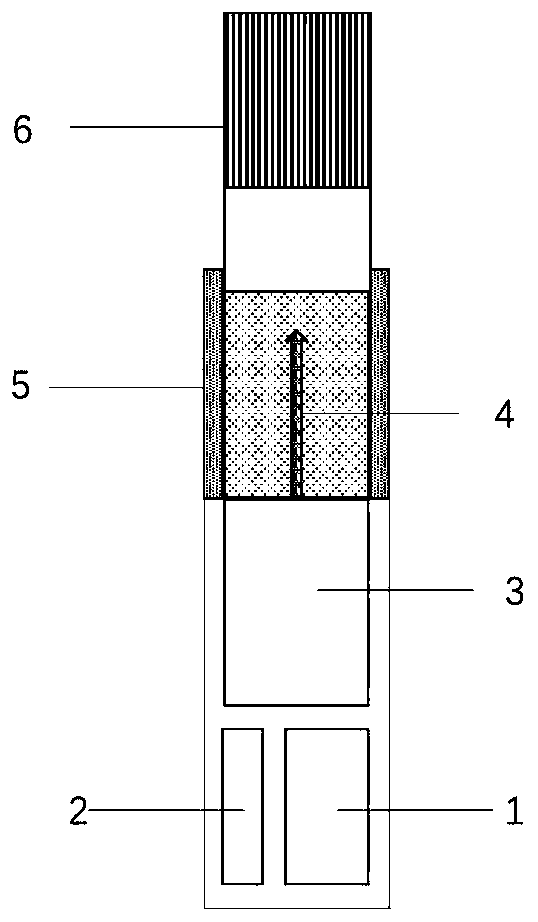

[0060] Embodiment 1: microwave heating non-burning smoking set of the present invention

[0061] The implementation mode of this embodiment is as follows:

[0062] The microwave heating and non-burning smoking appliance is composed of a power supply 1, a solid-state microwave source 3, a control system 4, a heating chamber 5 and an inner conductor 4 located in the heating chamber; the inner conductor is made of pure iron material and has a shape of It is umbrella-shaped, and two inner conductors are independently fixed around the heating cavity in parallel. The impedance is 40Ω, and the length is smaller than the length of the heating cavity. The microwave frequency of the solid-state microwave source is 2.45GHz.

[0063] The inner conductor of this embodiment is placed in the heating chamber of a microwave heating smoking appliance to obtain a magnetic microwave heating non-burning smoking appliance.

Embodiment 2

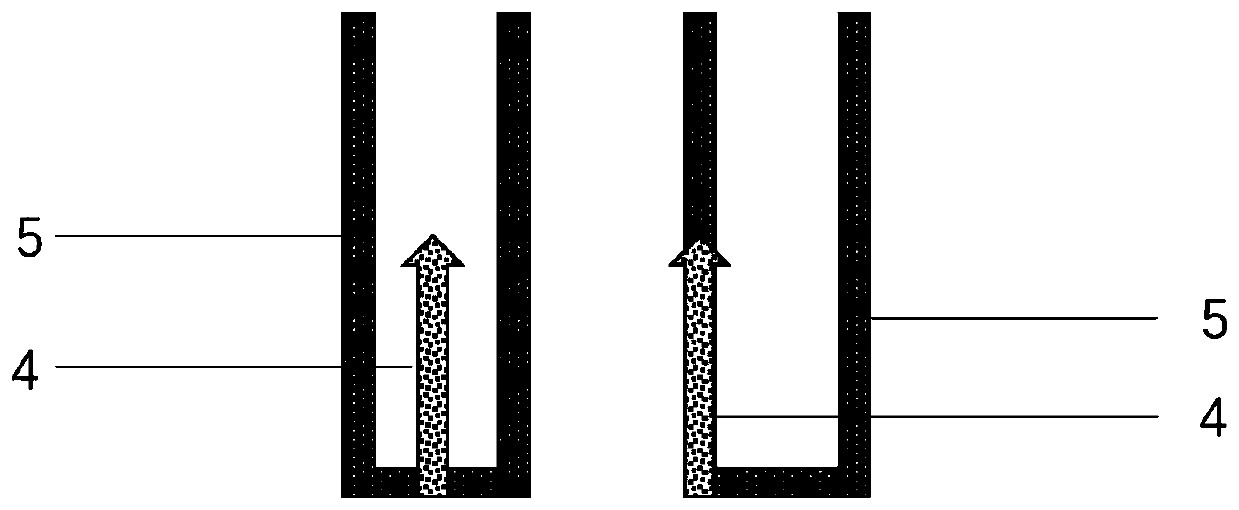

[0064] Embodiment 2: The conductor in the heating chamber of the microwave heating non-burning smoking appliance of the present invention

[0065] The implementation manner of this embodiment is the same as that of Embodiment 1, except that the inner conductor is made of pure copper material and is needle-shaped. It is independently fixed in the center of the heating chamber and is a coaxial line. The impedance is 35Ω, the length is less than the length of the heating cavity, and the microwave frequency of the solid-state microwave source is 2.45GHz.

[0066] The inner conductor of this embodiment is placed in the heating chamber of a microwave heating smoking appliance to obtain a magnetic microwave heating non-burning smoking appliance.

Embodiment 3

[0067] Embodiment 3: The conductor in the heating chamber of the microwave heating non-burning smoking appliance of the present invention

[0068] The implementation of this example is the same as that of Example 1, except that the inner conductor is made of copper-aluminum alloy material, and its shape is twist-shaped. It is embedded in the ceramic and then independently fixed in the center of the heating chamber. The coaxial line has an impedance of 38Ω and a length shorter than the length of the heating cavity, and the microwave frequency of the solid-state microwave source is 2.45GHz.

[0069] The inner conductor of this embodiment is placed in the heating chamber of a microwave heating smoking appliance to obtain a magnetic microwave heating non-burning smoking appliance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance | aaaaa | aaaaa |

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com