High-aroma heat-not-burn tobacco and preparation method thereof

A heat-not-burn, smoke-flavoring technology, applied in tobacco, tobacco preparation, tobacco processing, etc., can solve the problems of insufficient smoke characteristics, increased smoking experience, and weak richness of smoke aroma, etc., to achieve an overall increase in smoking experience , Avoid volatilization loss, obvious effect of flue gas characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

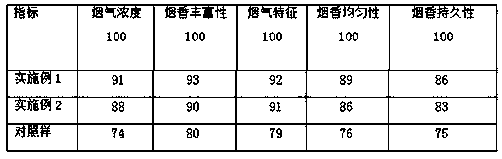

Examples

Embodiment 1

[0032] Prepare as follows:

[0033] (1) Microwave puffing: Microwave puffing and crushing the dried tobacco stems, sieving, and collecting 20-40 mesh puffed tobacco stem particles;

[0034] (2) Tobacco leaves crushing: crushing the tobacco leaves, sieving, and selecting and collecting 100 mesh tobacco leaf particles;

[0035] (3) Suspension preparation: Mix the mixture containing polyol, pure water, absolute ethanol, tobacco extract, tobacco flavor, binder and dispersion aid with the tobacco particles in step (2) in a certain mass ratio into a uniform suspension;

[0036] (4) Spraying: evenly spray the suspension in step (3) on the puffed tobacco stem particles collected in step (1) at a mass ratio of 3:1, and let stand for 6 to 8 hours;

[0037] (5) Drying equilibrium: After standing still in step (4), dry the material at 80°C for 1 hour, and transfer it to the equilibrium condition (temperature 22°C, relative humidity 60%) for 24 hours to make the required tobacco .

[0...

Embodiment 2

[0040] In the step (3), glycerol, pure water, absolute ethanol, flue-cured tobacco extract, β-dihydrodamascone, sodium carboxymethylcellulose, and polyethylene glycol 400 are mixed according to the mass ratio of 20:90:20 :8:12:5:5, and mix it with the tobacco particles in step (2) at a ratio of 12:1 to make a suspension. The rest of the preparation method and steps (1)-(4) are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com