Preparation method of heat-not-burn reconstituted tobacco through roll-in method and application thereof

A heat-not-burn and reconstituted tobacco leaf technology, which is applied in the application, preparation of tobacco, and cigar manufacturing, can solve the problems of good processing resistance and achieve the effects of good processing resistance, increased surface area, and non-sticking surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

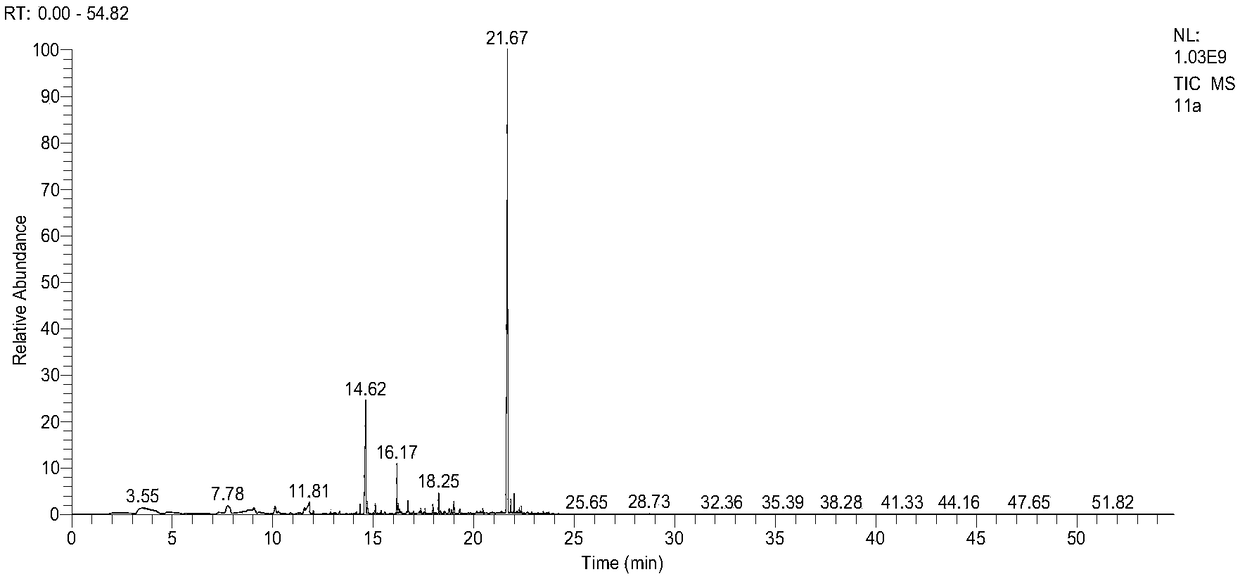

Image

Examples

Embodiment 1

[0032] A method for preparing heated non-combustion reconstituted tobacco by rolling method, specifically including the following steps:

[0033] (1) Preparation of raw materials: prepare raw materials according to the mass percentage ratio: 48% of tobacco raw materials, 32% of atomizing agent, 5% of solid adhesive, 3% of tobacco flavor, 1% of fiber, and 11% of warm water;

[0034] (2) Dry material mixing and crushing: Put the tobacco leaf and solid adhesive (mixture of CMC, PAC and sodium alginate, the mass ratio is 1:1:1) into the crusher according to the proportion, and crush to 100 mesh. At this time, the dry materials After being crushed at high speed, it is evenly mixed;

[0035] (3) Wet material mixing and dispersing: fiber (wood pulp) and 30℃ warm water are poured into the material bucket in proportion, stirred at a high speed of 300r / min and mixed evenly, decomposed and dispersed, and then add the atomizing agent of the above step 1) mass ratio (Glycerol and propylene glyco...

Embodiment 2

[0039] A preparation method for heating and non-combustion reconstituted tobacco by rolling method, specifically comprising the following steps:

[0040] (1) Preparation of raw materials: prepare raw materials according to the mass percentage ratio: 55% of tobacco raw materials, 25% of atomizing agent, 8% of solid adhesive, 2% of tobacco flavor, 2% of fiber, and 8% of warm water;

[0041] Dry material mixing and crushing: Put the tobacco raw materials, solid adhesive (CMC, sodium alginate and egg curd, mass ratio 1:1:1) into the crusher according to the proportion, crush to 150 mesh, and then mix by high-speed crushing Evenly

[0042] (3) Mixing and dispersing of wet materials: fiber (tobacco fiber and wood pulp, mass ratio is 1:5) and 50℃ warm water are poured into the material bucket according to the proportion, 400r / min high-speed stirring and mixing uniformly, dissolve and disperse, and then add the above Step 1) The atomizing agent glycerin with the mass ratio, continue to mix ...

Embodiment 3

[0046] A method for preparing heated non-combustion reconstituted tobacco by rolling method, specifically including the following steps:

[0047] (1) Preparation of raw materials: prepare raw materials according to the mass percentage: 52% of tobacco raw materials, 25% of atomizers, 4% of solid adhesives, 4% of tobacco flavors, 3% of fibers, and 12% of warm water;

[0048] (2) Dry material mixing and crushing: Put the tobacco raw materials and solid adhesives (CMC, sodium alginate, ethyl cellulose, PAC, mass ratio 1:1:1:1) into the pulverizer according to the proportion, and pulverize to 200 At this time, it is pulverized at high speed and mixed evenly;

[0049] (3) Mixing and dispersing of wet materials: fiber (bamboo pulp and wood pulp, mass ratio 2:5) and 55℃ warm water are poured into the material bucket in proportion, stirred at a high speed of 500r / min and mixed evenly, dissolved and dispersed, and then added to the above Step 1) Atomizing agent with mass ratio (glycerol and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com