Low-temperature cigarette processing method and application thereof

A technology of low-temperature cigarettes and processing methods, which is applied in the fields of application, tobacco, and tobacco preparation. It can solve the problems of easy adhesion on the surface of tobacco raw materials, uneven distribution of atomizing agents, and low production efficiency. Good chemical effect and improved processing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

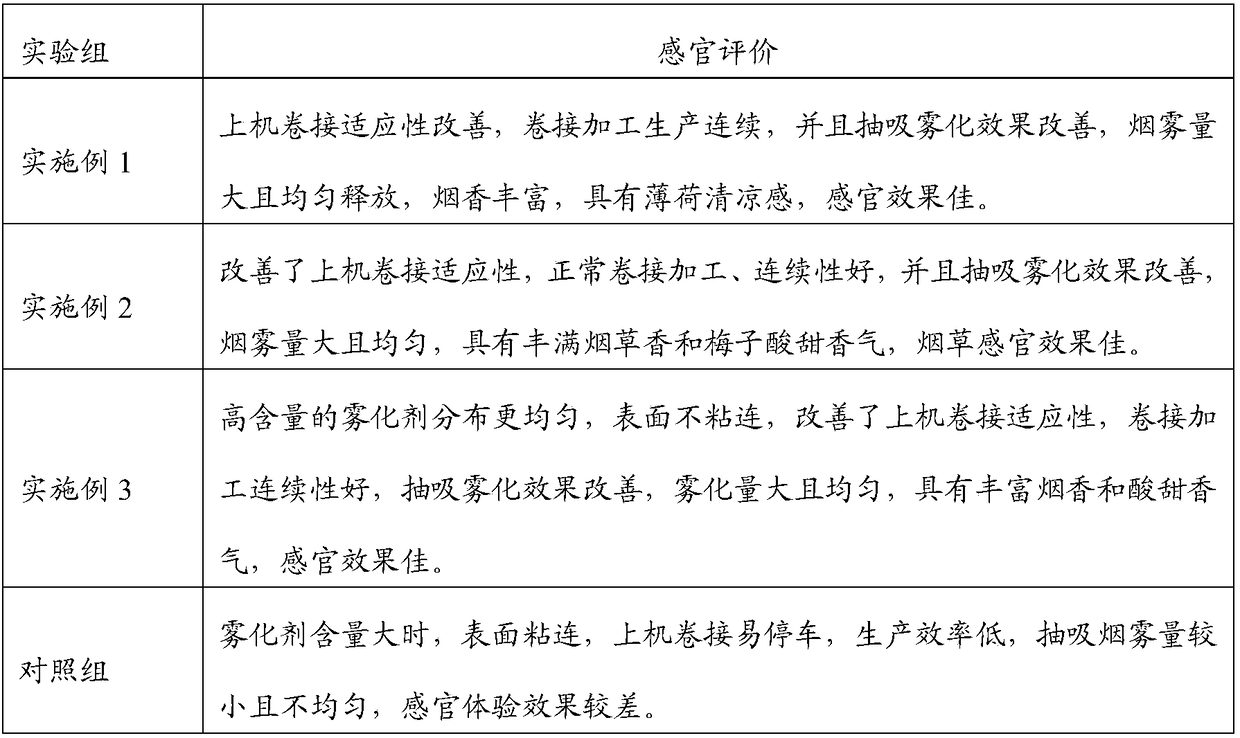

Examples

Embodiment 1

[0030] A method for processing low-temperature cigarettes, specifically comprising the steps of:

[0031] (1) Raw material preparation: 40% of tobacco raw material, 21% of atomizing agent, 2% of adhesive, 1% of flavor and fragrance for tobacco, 0.1% of ammonium bicarbonate, 1% of fiber, and 34.9% of water. A kind of raw material; Described tobacco raw material is tobacco leaf, tobacco stem, shredded tobacco powder, and the mass ratio is 1:0.1:0.1; Described atomizing agent is propylene glycol, glycerol, food grade, and the mass ratio is 1:0.1:0.1; 12; the adhesive is propylene glycol alginate and bone glue, and the mass ratio between the two is 1:0.6; the flavoring for tobacco is mint flavoring and tobacco extract, and the mass ratio is 1:2; The ammonium bicarbonate is food grade; the fibers are wood pulp fibers and hemp pulp fibers in a ratio of 1:0.1; the water is 2°C water;

[0032] (2) Mixing and pulverizing of dry materials: putting tobacco raw material and solid adhesiv...

Embodiment 2

[0040] The present invention is realized through the following technical solutions:

[0041] A method for processing low-temperature cigarettes, specifically comprising the steps of:

[0042](1) Raw material preparation: 48% of tobacco raw material, 26% of atomizing agent, 10% of adhesive, 1% of flavor and fragrance for tobacco, 2% of ammonium bicarbonate, 3% of fiber, and 10% of water. A kind of raw material; The described tobacco raw material is the mixture of tobacco leaves, tobacco stems, and shredded tobacco powder, and the mass ratio of the three is 1:0.20:0.15; The described atomizing agent is a mixture of propylene glycol and glycerol, food grade, quality The ratio is 1:10; the adhesive is a mixture of casein glue and sodium alginate, and the mass ratio between the two is 1:0.6; the tobacco flavor is a mixture of tobacco extract and plum extract , the mass ratio between the two is 1:1; the ammonium bicarbonate is food grade; the fiber is a mixture of wood fiber and si...

Embodiment 3

[0051] The present invention is realized through the following technical solutions:

[0052] A method for processing low-temperature cigarettes, specifically comprising the steps of:

[0053] (1) Raw material preparation: 52% of tobacco raw material, 12% of atomizing agent, 5% of adhesive, 1% of flavor and fragrance for tobacco, 5% of ammonium bicarbonate, 5% of fiber, and 20% of water. A kind of raw material; The described tobacco raw material is the mixture of tobacco leaves, tobacco stems, and shredded tobacco dust, and the mass ratio of the three is 1:0.15:0.15; The described atomizing agent is a mixture of propylene glycol and glycerin, food grade, quality The ratio is 1:50; the adhesive is a mixture of casein glue and sodium alginate, and the mass ratio is 3:8; the tobacco flavor is a mixture of tobacco extract, jujube extract, and plum extract. The mass ratio between the three is 1:0.5:0.5; the ammonium bicarbonate is food grade; the fiber is wood fiber; the warm water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com