Electrical-heat-not-burn smoking set and temperature control device thereof

A temperature control device and electric heating technology, used in tobacco, smoker's products, applications, etc., can solve the problems of the consistency of the initial resistance value of the heating element, increase the calibration process, inaccurate temperature measurement, etc., so as to facilitate the replacement of the heating element. , The effect of simplifying the production process and precise temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

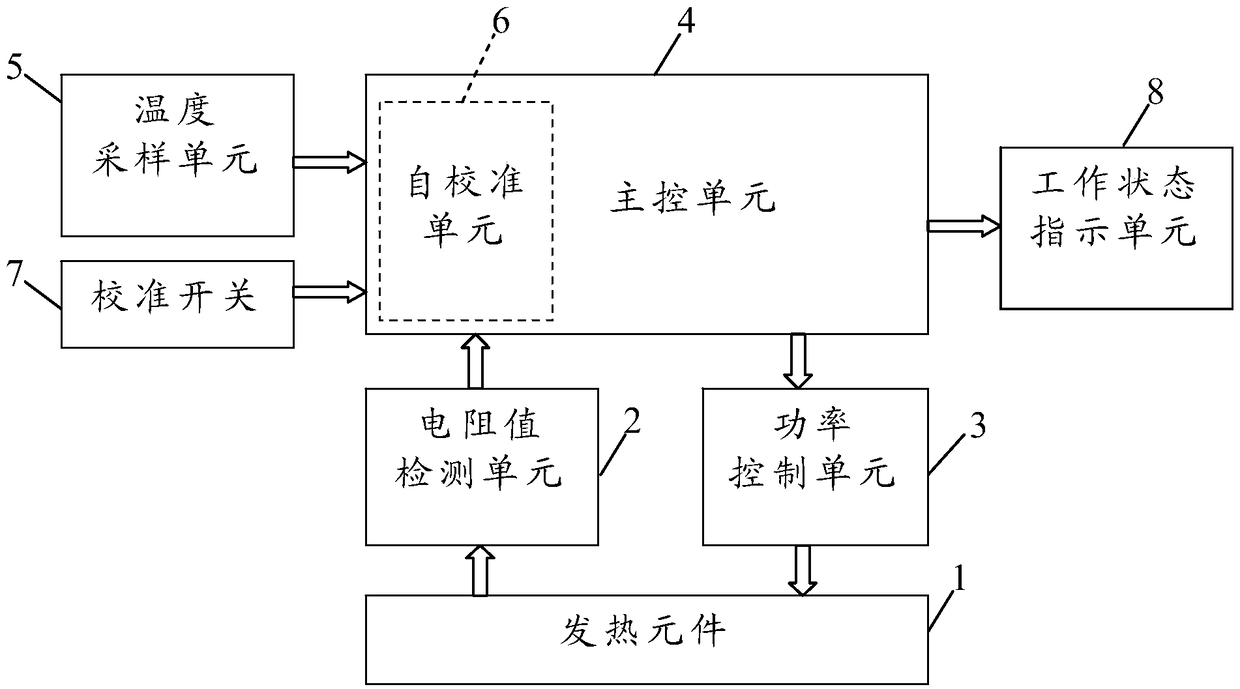

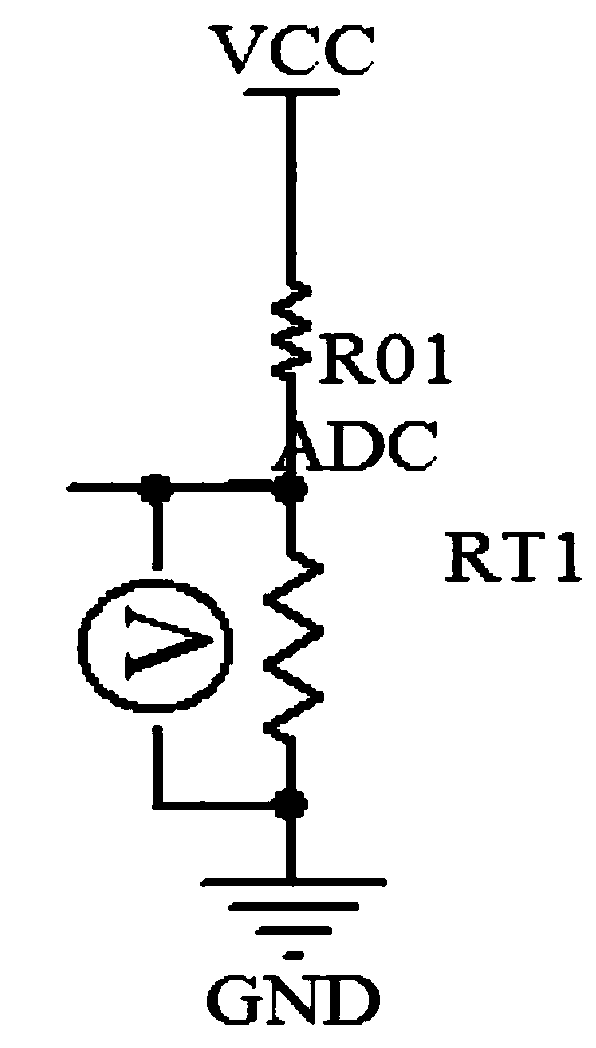

[0026] Please refer to figure 1 , the temperature control device of the electric heating non-burning smoking appliance includes: a heating element 1 of the smoking appliance, a resistance value detection unit 2 , a power control unit 3 , a main control unit 4 , a temperature sampling unit 5 , a self-calibration unit 6 and a calibration switch 7 .

[0027] Wherein, the resistance value of the heating element 1 changes with its own temperature, and a ceramic heating element coated with a functional layer can be used, or a heating element made of other materials whose resistance value changes with temperature, such as a semiconductor material. into the heating element and so on. These heating elements are currently commercially available.

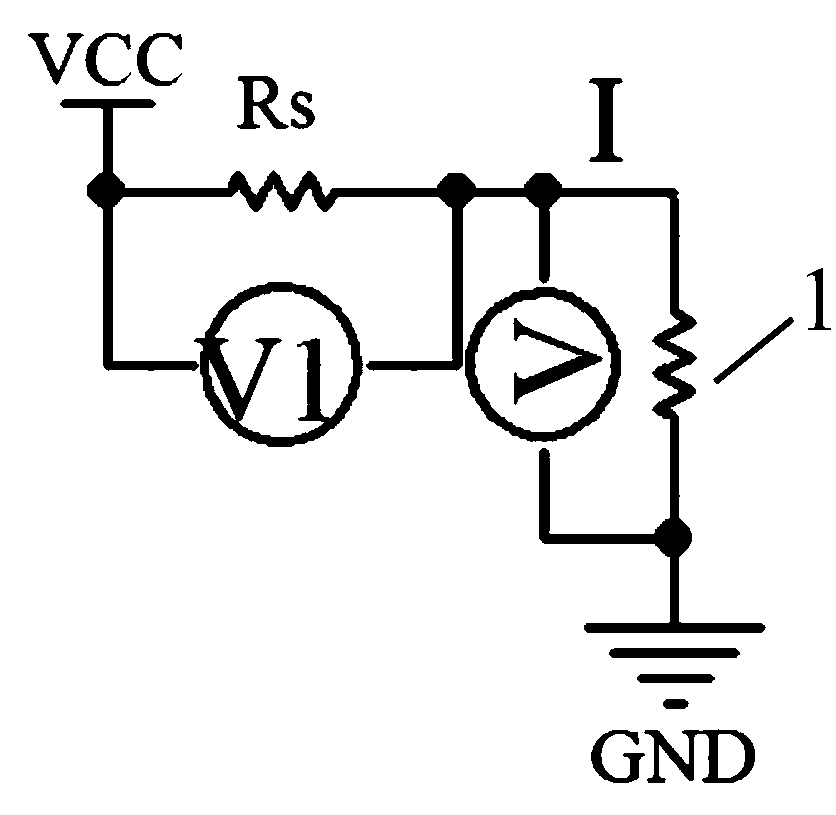

[0028] The resistance value detecting unit 2 is connected with the heating element 1 and is used for detecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com