Tobacco substrate suitable for heat-not-burn effect and preparation method thereof

A heat-not-burn and tobacco technology, applied in tobacco, tobacco preparation, application, etc., can solve the problem of low efficiency of smoke release, improve use efficiency, meet the requirements of production technology, save energy consumption and energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

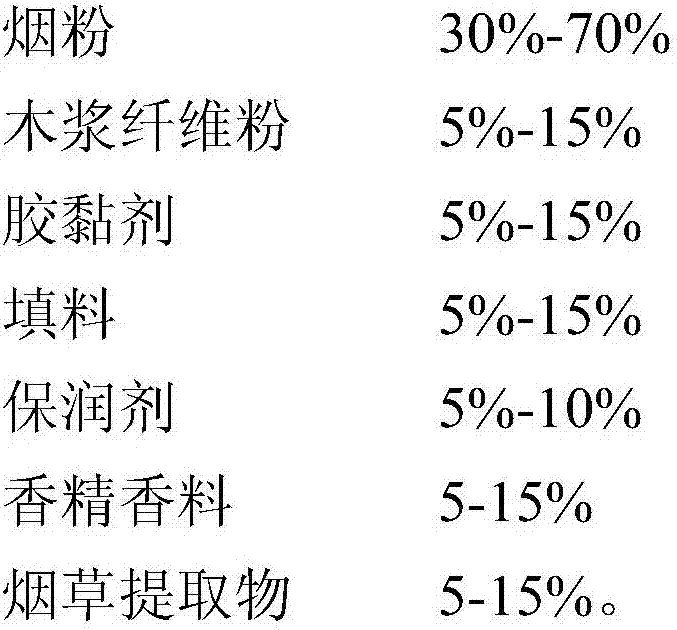

Method used

Image

Examples

Embodiment 1

[0042] (1) Grind the raw tobacco into powder with a milling machine, pass through a 60-mesh sieve completely, and the particle size distribution is 60-200 mesh, and set aside.

[0043](2) The wood pulp fiber is ground into powder with a pulverizer respectively, passes through a 60-mesh sieve completely, and the particle size is distributed at 60-200 mesh, and is set aside.

[0044] (3) Take tobacco powder 39g, wood paddle powder 9.75g, guar gum 3.25g, calcium carbonate 3.25g, propylene glycol 3.25g, essence fragrance and tobacco extract 6.5g and mix together, set aside;

[0045] (4) Add 6 times the quality of water to the prepared (3), stir with a mixer, mix each component with water evenly, form a loose agglomerate slurry, divide it into 5 parts for later use;

[0046] (5) Spread the plastic wrap on the cutting board mold with a plastic bottom, take 1 portion of the slurry in step (4) and put it on the plastic wrap, and roll it into a size of 20cm×30cm with a roller; take ano...

Embodiment 2

[0052] (1) Grind the raw tobacco into powder with a milling machine, pass through a 60-mesh sieve completely, and the particle size distribution is 60-200 mesh, and set aside.

[0053] (2) The wood pulp fiber is ground into powder with a pulverizer respectively, passes through a 60-mesh sieve completely, and the particle size is distributed at 60-200 mesh, and is set aside.

[0054] (3) Take tobacco powder 39g, wood paddle powder 9.75g, guar gum 3.25g, calcium carbonate 3.25g, propylene glycol 3.25g, essence fragrance and tobacco extract 6.5g and mix together, set aside;

[0055] (4) Add 6 times the quality of water to the prepared (3), stir with a mixer, mix each component with water evenly, form a loose agglomerate slurry, divide it into 5 parts for later use;

[0056] (5) Spread the plastic wrap on the cutting board mold with a plastic bottom, take 1 portion of the slurry in step (4) and put it on the plastic wrap, and roll it into a size of 30cm×30cm with a roller; take an...

Embodiment 3

[0063] (1) Grind the raw tobacco into powder with a milling machine, pass through a 60-mesh sieve completely, and the particle size distribution is 60-200 mesh, and set aside.

[0064] (2) The wood pulp fiber is ground into powder with a pulverizer respectively, passes through a 60-mesh sieve completely, and the particle size is distributed at 60-200 mesh, and is set aside.

[0065] (3) Take 39g of tobacco powder, 9.75g of wood paddle powder, 3.25g of guar gum, 3.25g of calcium carbonate, 3.25g of propylene glycol, 9.75g of flavor and fragrance, and 6.5g of iron powder, and mix together for use;

[0066] (4) Add 8 times the quality of water to the prepared (3), stir with a mixer, mix each component with water evenly, form a loose agglomerate slurry, divide it into 5 parts for later use;

[0067] (5) Lay the preservative film flatly on the cutting board mould, which has a plastic bottom, take 1 part of the slurry in step (4) and put it on the preservative film, and roll it into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com