Fuming product and preparation method and application thereof

A technology for smoking products and tobacco, applied in the field of tobacco, can solve problems such as unfavorable insertion and removal, unfavorable cavity cleaning, heating cavity pollution, etc., and achieve the effects of improving smoking experience, increasing liquid adsorption capacity, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the inorganic binder used is bentonite with a particle size not greater than 48 μm. The inorganic adsorption material used is diatomite, and the particle size is not greater than 48 μm. The tobacco used is Yunnan flue-cured tobacco powder with a particle size not greater than 250 μm. In this embodiment, the atomizing agent is glycerol, and the essence is vanillin.

[0032] The mass ratio of bentonite, diatomite, flue-cured tobacco powder, glycerin, water and vanillin is 400:400:100:1000:300:30.

[0033] The preparation method of the smoking product in this embodiment: mix glycerin, water and vanillin evenly to obtain a mixed solution, and set aside; mix bentonite, diatomaceous earth and Yunnan flue-cured tobacco powder evenly to obtain a mixed dry material; The solution is added to the mixed dry material to obtain a mixed wet material. Then, a long rod-shaped smoking product with a diameter of 7 mm was extruded by a screw extruder, and cut into le...

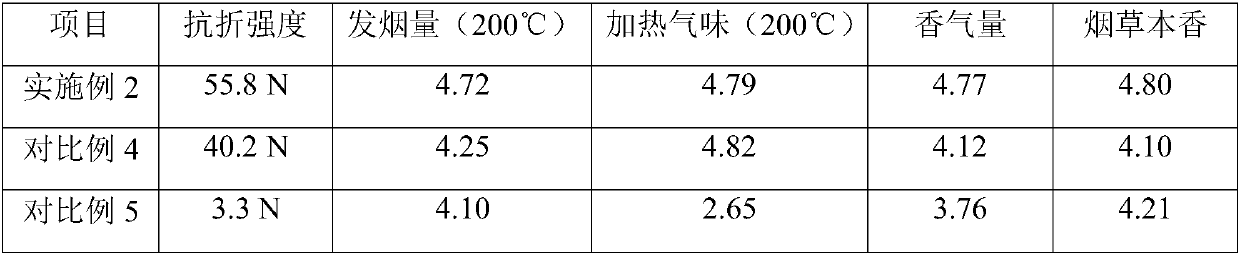

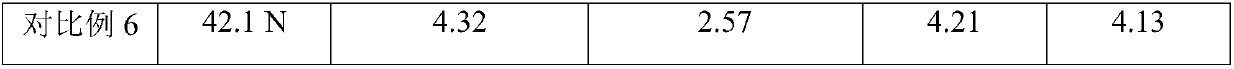

Embodiment 2

[0035] In this embodiment, the inorganic binder used is bentonite with a particle size not greater than 48 μm. The inorganic adsorption material used is diatomite, and the particle size is not greater than 48 μm. The tobacco used is Yunnan flue-cured tobacco powder with a particle size not greater than 250 μm. In this embodiment, the atomizing agent is glycerol, and the essence is vanillin.

[0036] The mass ratio of bentonite, diatomite, flue-cured tobacco powder, glycerin, water and vanillin is 400:400:100:600:300:30.

[0037] The preparation method of the smoking product in this embodiment: mix glycerin, water and vanillin evenly to obtain a mixed solution, and set aside; mix bentonite, diatomaceous earth and Yunnan flue-cured tobacco powder evenly to obtain a mixed dry material; The solution is added to the mixed dry material to obtain a mixed wet material. Then, a long rod-shaped smoking product with a diameter of 7 mm was extruded by a screw extruder, and cut into lengt...

Embodiment 3

[0039] In this embodiment, the inorganic binder used is bentonite with a particle size not greater than 48 μm. The inorganic adsorption material used is diatomite, and the particle size is not greater than 48 μm. The tobacco used is Yunnan flue-cured tobacco powder with a particle size not greater than 250 μm. In this embodiment, the atomizer is glycerol, and the essence is cocoa tincture.

[0040] The mass ratio of bentonite, diatomite, flue-cured tobacco powder, glycerol, water, and cocoa tincture is 500:300:200:800:200:10.

[0041] The preparation method of the smoking product in this embodiment: mix glycerin, water and cocoa tincture evenly to obtain a mixed solution for later use; mix bentonite, diatomaceous earth and Yunnan flue-cured tobacco powder evenly to obtain a mixed dry material; mix the mixed solution Add to mixed dry ingredients to obtain mixed wet ingredients. Then, a long rod-shaped smoking product with a diameter of 7 mm was extruded by a screw extruder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com