Cooling filter rod, fuming product and application

A mouth stick and cooling section technology, applied in the field of smoking products, can solve problems such as growth limit, difficulty in material cooling, melting, etc., to achieve the effect of improving comfort and satisfaction, solving excessive water vapor and suitable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

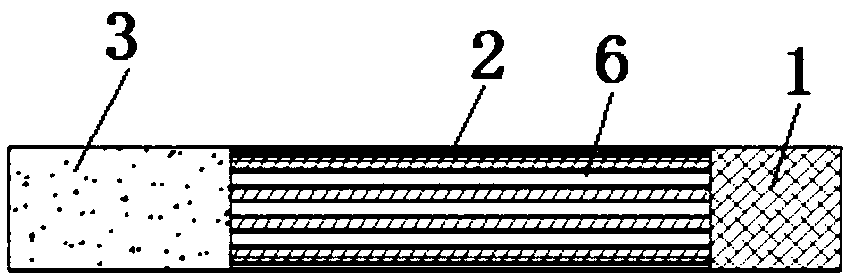

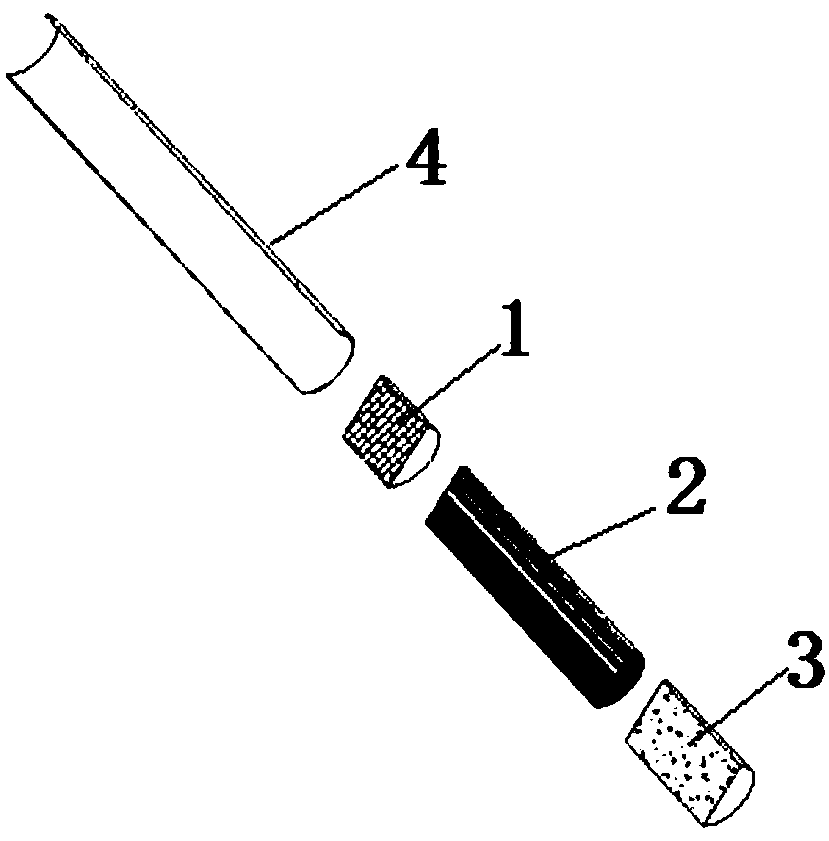

[0045] Such as figure 1 As shown, the smoking product in this embodiment is a heat-not-burn cigarette, including a filter section 1, a cooling section 2, and a smoking section 3 connected in sequence, and the filter section is made of special acetate fiber with cooling and low smoke retention. The cooling section is formed by wrapping the cooling rod with molding paper 4, and the cooling rod is mainly formed by paper coated with a phase change cooling material.

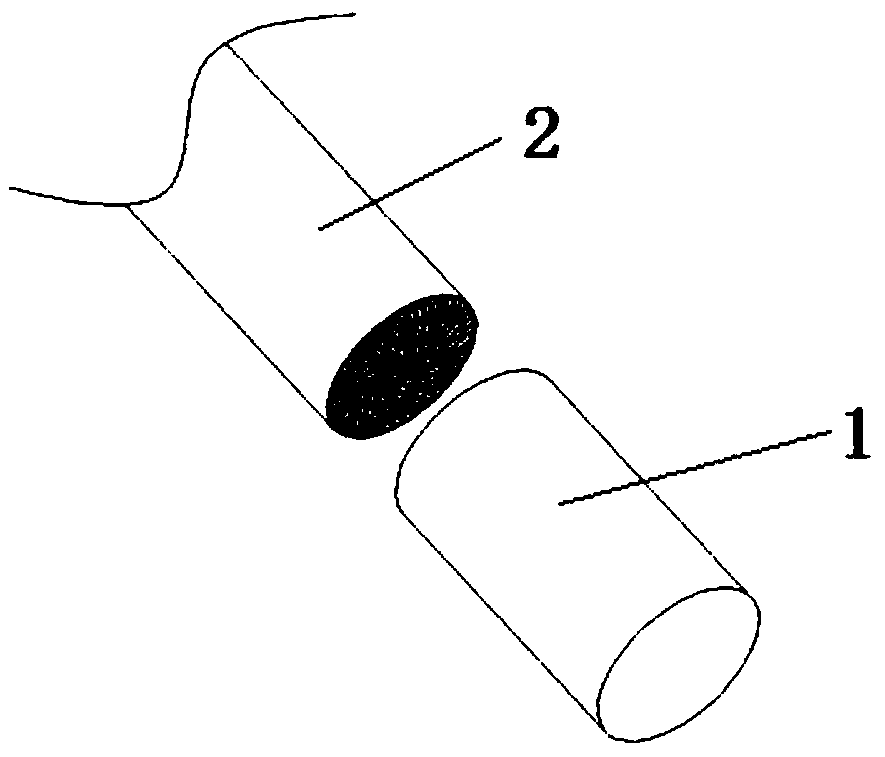

[0046] Wherein, the cooling rod has a plurality of passages 6 passing through both ends of the cooling rod, and the total specific surface area of the plurality of passages accounts for 20%-30% of the surface area of the cooling paper.

[0047] The paper is a cellulose paper with a strong ability to absorb water but a weak ability to absorb tar. The basis weight of the paper is 80g / m 2 .

[0048] The cooling material is CH 3 COONa·3H 2 O. The coating amount of the cooling material is 5g / m 2 .

[0049] Afte...

Embodiment 2

[0053] Repeat Example 1, only increase the coating amount of cooling material to 10g / m 2 . Through comparative research, it is found that the cooling section designed by the present invention is used to replace the wrinkled PLA film cooling section in the iQOS cigarette, and the maximum smoke temperature at the inlet is 50°C, which is 11°C lower than that of the iQOS inlet; at the same time, the temperature in the smoke The total particulate matter in the iQOS smoke is 14.5mg / stick, which is only 0.5mg / stick lower than the total particulate matter in the iQOS smoke. Table 1).

Embodiment 3

[0055] Repeat Example 1, only increase the coating amount of cooling material to 20g / m 2 . Through comparative research, it is found that the cooling section designed by the present invention is used to replace the wrinkled PLA film cooling section in the iQOS cigarette, and the maximum smoke temperature at the inlet is 43°C, which is 18°C lower than that of the iQOS inlet; The total particulate matter in the iQOS smoke is 15.2mg / stick, which is 0.2mg / stick higher than the total particulate matter in iQOS smoke, achieving the effect of cooling and low retention. The puff sensory quality of the smoke was significantly improved (see Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com