Method for preparing sectional aerosol generating matrix rod in intermittent spraying manner

An aerosol generation and segmented technology, which is applied in applications, tobacco, e-liquid filter elements, etc., can solve problems such as inability to bond, uneven dispersion of adhesives, and small air flow, and achieve the effect of ensuring the amount of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment is a method for intermittently spraying a segmented aerosol-generating matrix rod, which comprises the following steps:

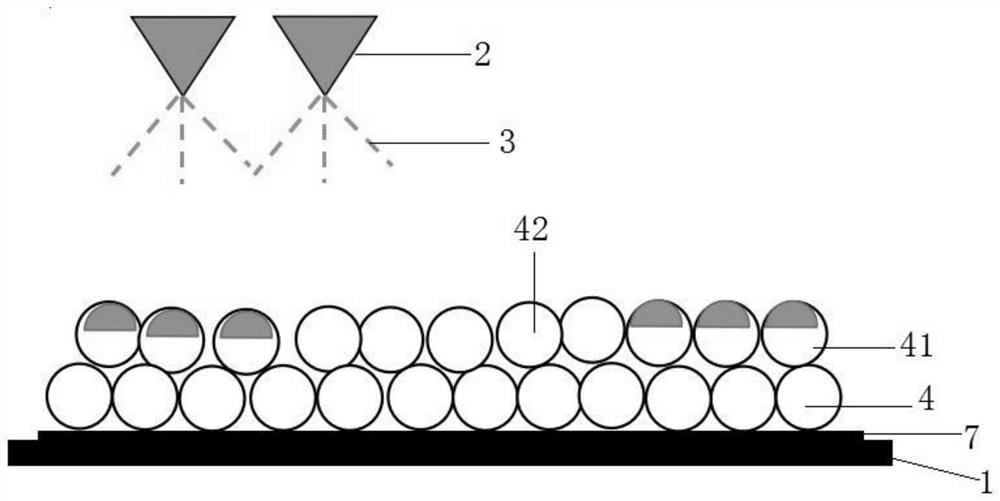

[0046] (1) Take the anti-seepage cigarette paper and spread it on the conveyor belt 1, then take the tobacco particles 4 and spread it on the anti-seepage cigarette paper 7, and the conveyor belt 1 carries the anti-seepage cigarette paper 7 and tobacco at a fixed speed Particle 4 run;

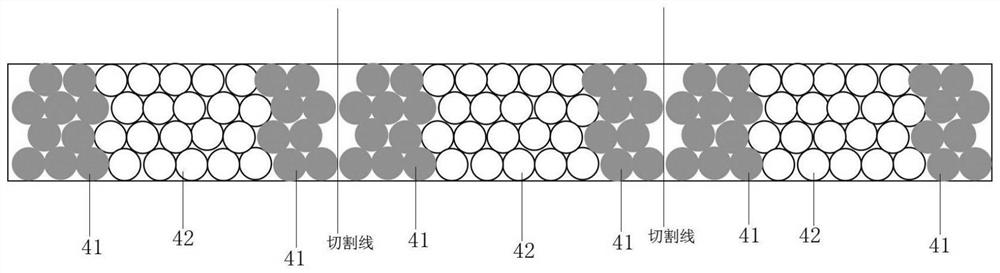

[0047] (2) There is a spray head (spray device) 2 above the conveyor belt 1 for spraying the adhesive, and the spray head intermittently sprays the adhesive 3 on the top of the tobacco particles, so that the tobacco particles on the anti-seepage cigarette paper 7 The gluing area, non-gluing area and gluing area are arranged at intervals;

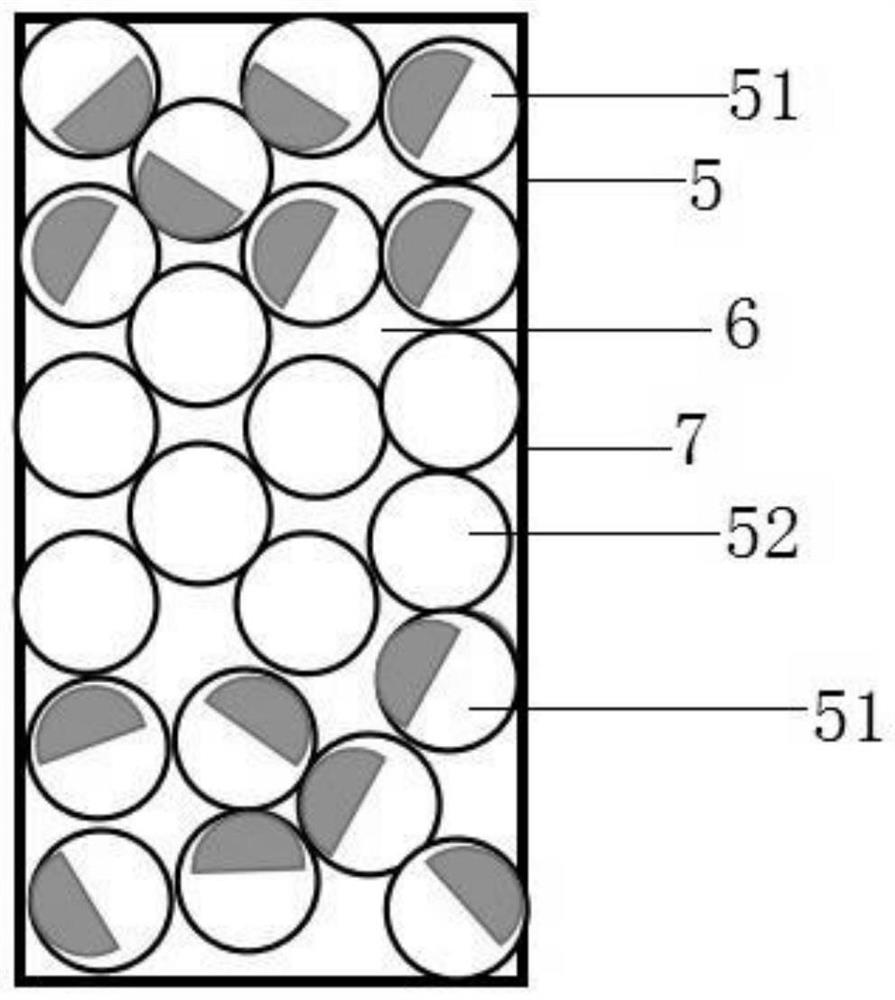

[0048] (3) Downstream of the conveyor belt running direction, there is a cigarette double-folding rolling device. With the operation of the conveyor belt, the cigarette double-folding rolling device wraps the tobacc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com