High-thermal-conductivity aluminum alloy and preparation method thereof

An aluminum alloy and high thermal conductivity technology, applied in the field of aluminum alloy materials, can solve the problems of electronic vibration obstruction and reduce the thermal conductivity of the alloy, and achieve the effects of convenient source, good die-casting performance and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing an aluminum alloy with high thermal conductivity, comprising the steps of:

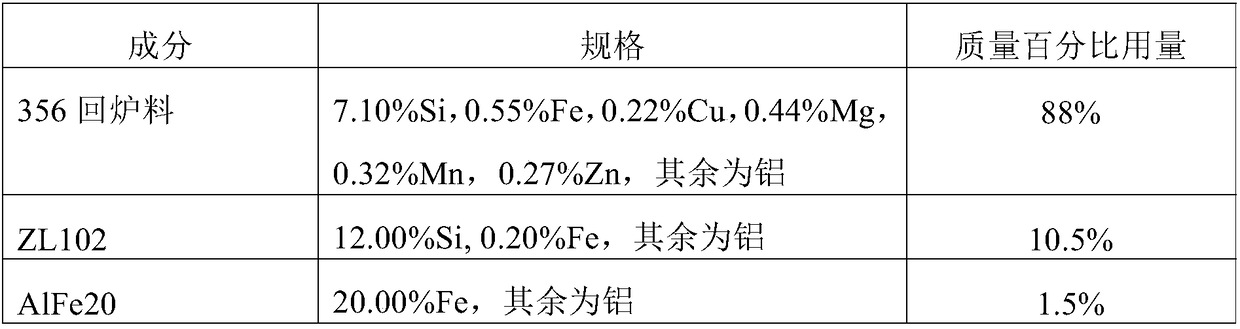

[0028] (1) Ingredients

[0029]

[0030] (2) Melting

[0031] Add 356 recharge, ZL102 and AlFe20 alloys into the melting furnace, then raise the temperature by 150°C per hour to 720°C, and stir for 3 minutes after the alloys are completely melted. In the intermediate transfer bag of molten aluminum, add commercial solid refining agent to the molten aluminum at a ratio of 4 / 1000, refine at 720-730°C, degas with high-purity argon, remove slag, and stand for 10 minutes.

[0032] (3) Die casting

[0033] The smelted alloy is used to shape the components of household appliances on a 1250-ton cold chamber die-casting machine. The casting size is 320×290×120mm, the mold preheating temperature is 150°C, the alloy pouring temperature is 660°C, and the injection speed is 3.0m / s. Boost pressure 85MPa.

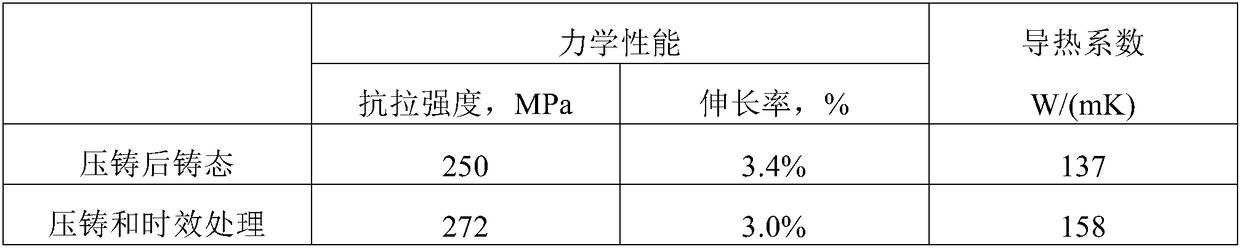

[0034] (4) heat treatment

[0035] The die casting of the communication ...

Embodiment 2

[0040] A method for preparing an aluminum alloy with high thermal conductivity, comprising the steps of:

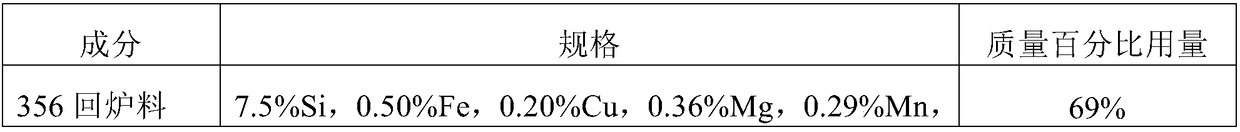

[0041] (1) Ingredients

[0042]

[0043]

[0044] (2) Melting

[0045]Add 356 recharge, ZL102 and AlFe20 alloys into the melting furnace, then raise the temperature by 150°C per hour to 720°C, and stir for 3 minutes after the alloys are completely melted. In the intermediate transfer bag of molten aluminum, add commercial solid refining agent to the molten aluminum at a ratio of 4 / 1000, refine at 720-730°C, degas with high-purity argon, remove slag, and stand for 10 minutes.

[0046] (3) Die casting

[0047] Using the smelted alloy, the communication components are formed on a 1600-ton cold chamber die-casting machine. The casting size is 410×320×142mm, the mold preheating temperature is 160°C, the alloy pouring temperature is 680°C, and the injection speed is 3.6m / s. The boost pressure is 90MPa.

[0048] (4) heat treatment

[0049] The die casting of the commu...

Embodiment 3 to Embodiment 9

[0054] The preparation method of the high thermal conductivity aluminum alloys in Examples 3 to 9 is the same as in Example 1, except that the aging treatment time is different, and the aging treatment time is 0.5 hour, 1 hour, 2 hours, 2.5 hours, 3.5 hours, For 4 hours and 5 hours, the performance test results of the die-casting and aging treatment in Examples 3-9 are shown in Table 3.

[0055] The performance detection result of table 3 embodiment 3~9

[0056]

[0057]

[0058] Embodiment 10 to Implementation 16

[0059] The preparation method of the high thermal conductivity aluminum alloys in Examples 10-16 is the same as in Example 1, except that the temperature of aging treatment is different, and the aging treatment temperatures are 120°C, 140°C, 155°C, 160°C, 170°C, 180°C and 200°C, performance test results of die casting and aging treatment in Examples 10-16 are shown in Table 4.

[0060] The performance detection result of table 4 embodiment 10~16

[0061] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com