Patents

Literature

36results about How to "High temperature regulation accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

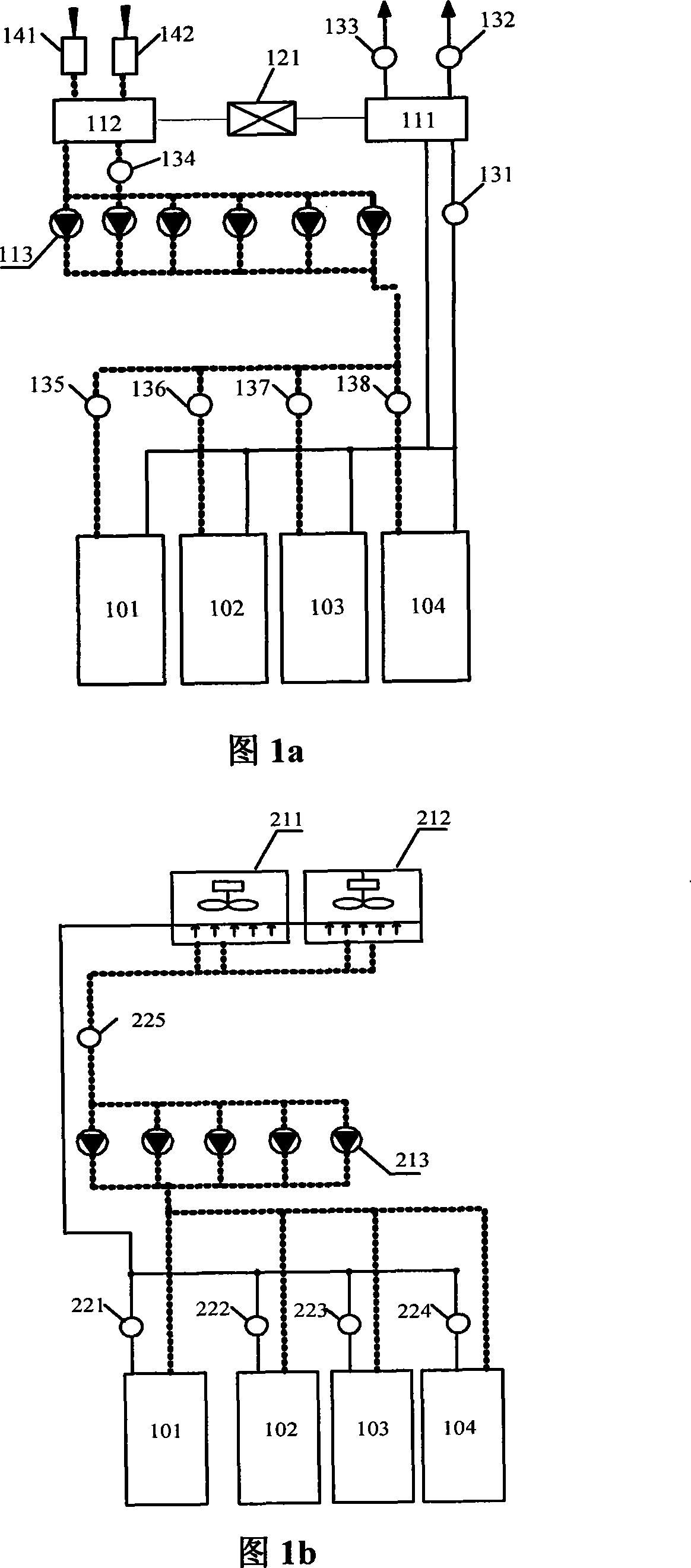

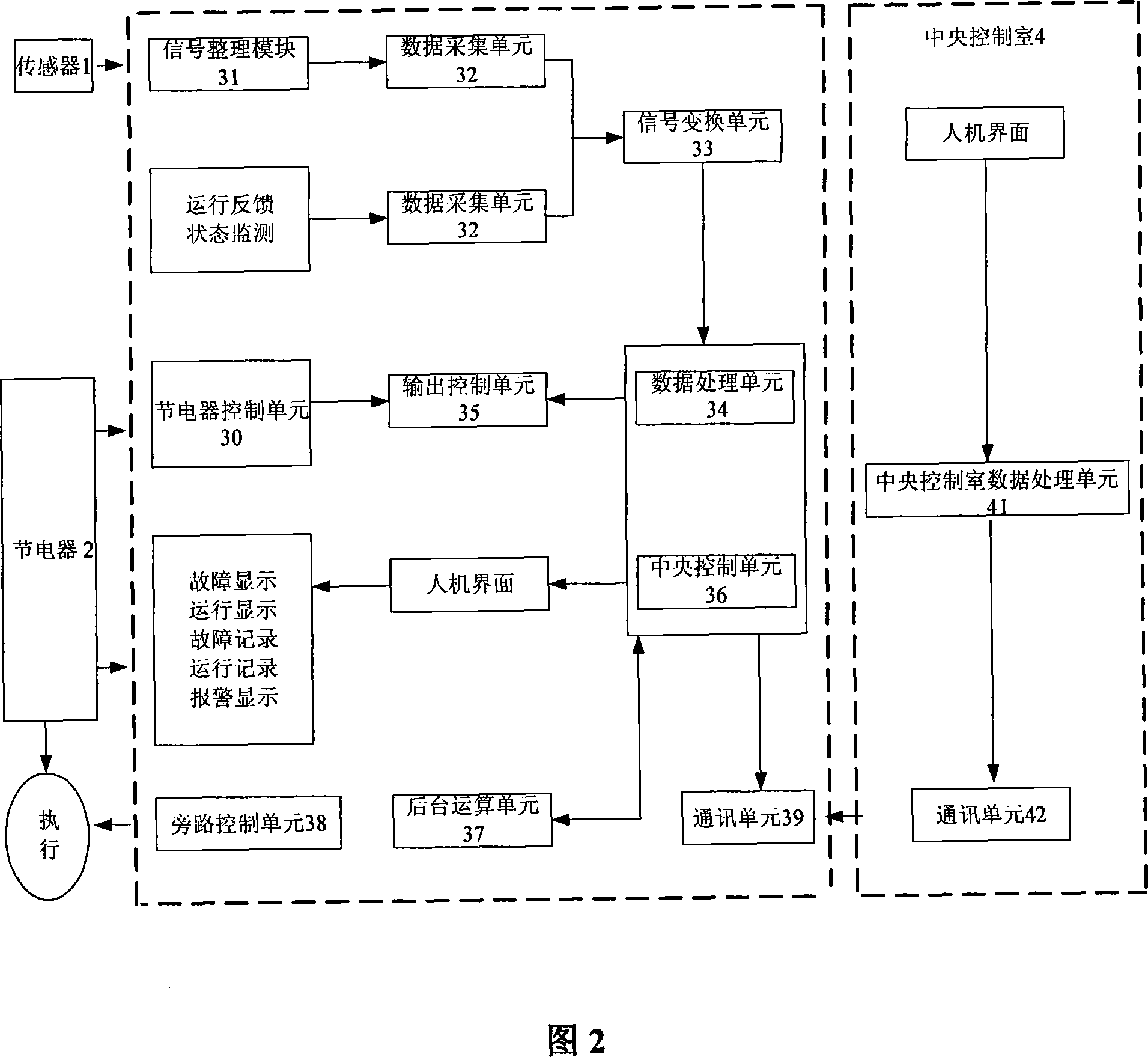

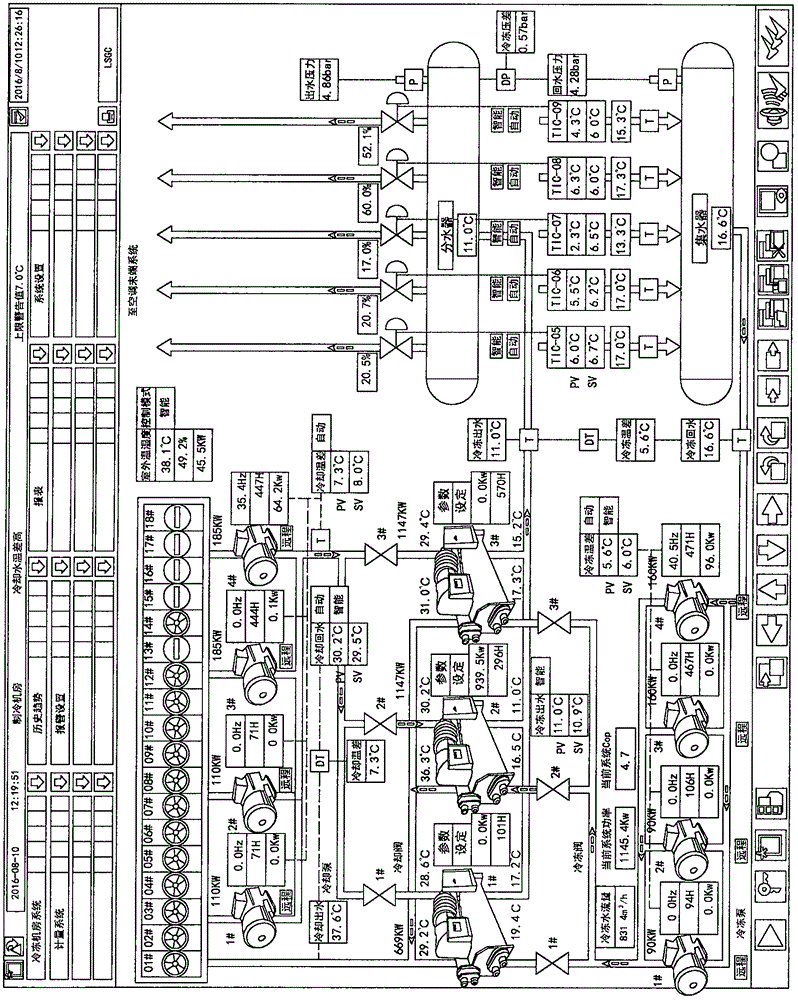

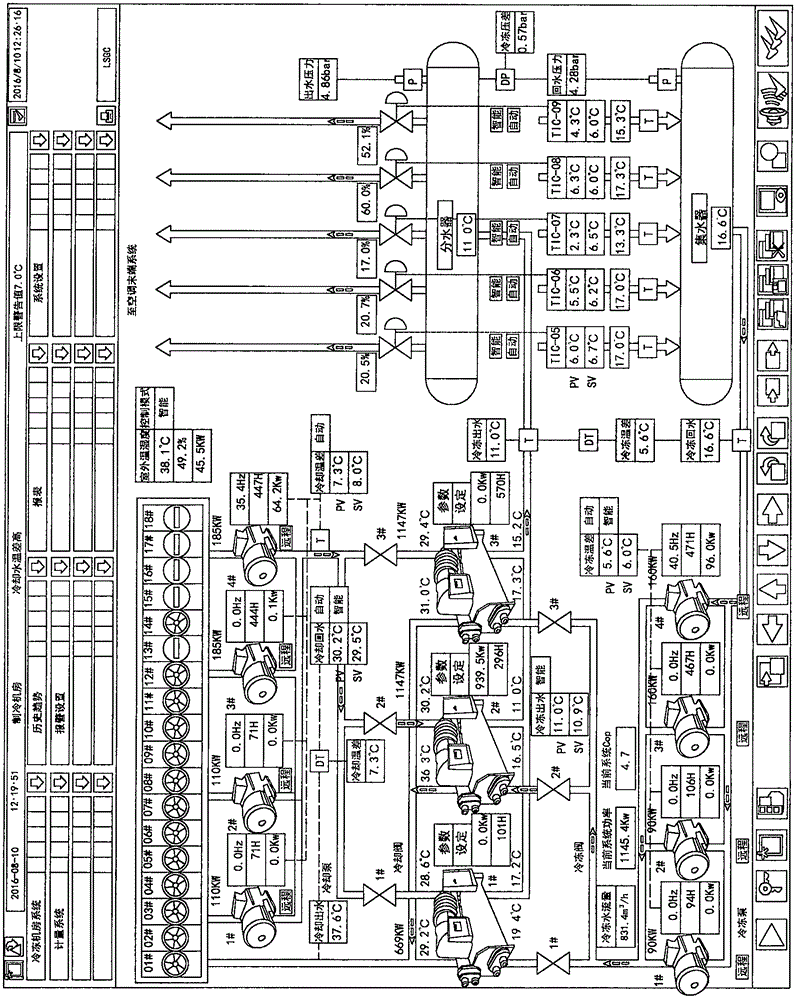

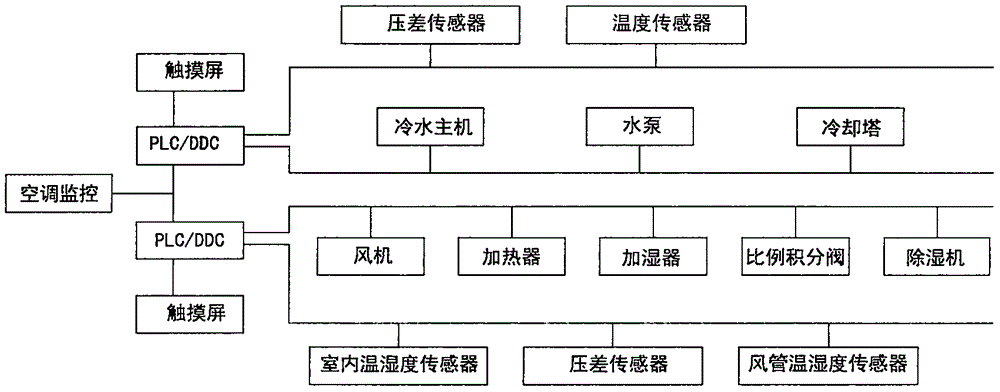

Electricity economizer centralized management method and system of central air-conditioning

InactiveCN101140096AEliminate shockReduce labor intensitySpace heating and ventilation safety systemsLighting and heating apparatusClosed loopEngineering

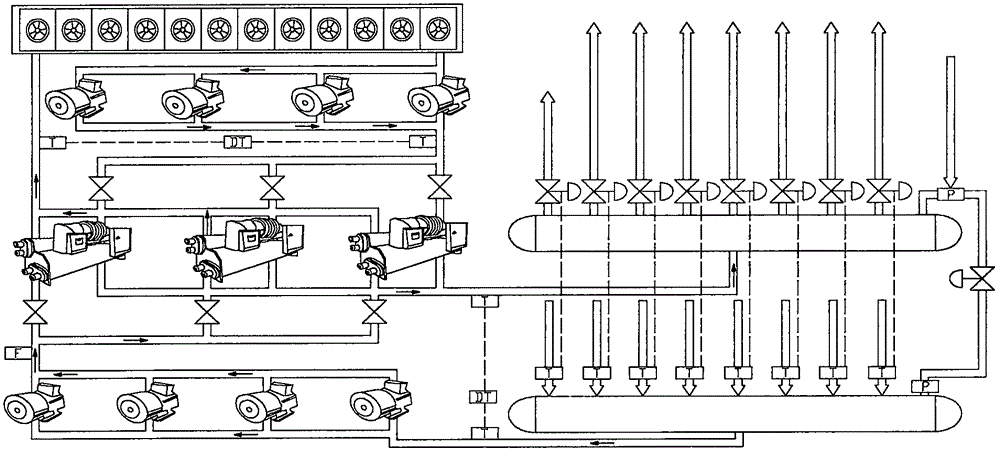

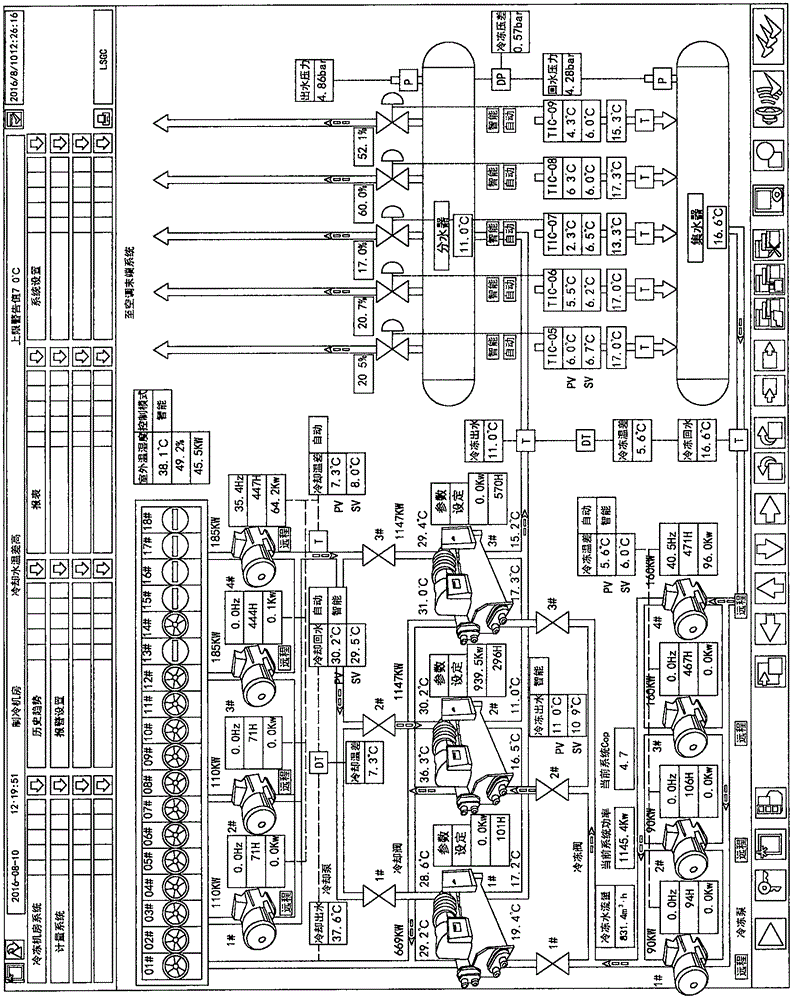

The invention relates to a method and a system for centralized management of an electric saver of a central air-conditioner; a water flow pressure difference sensor between a water supply main pipe and a return water main pipe of a central air-conditioner freezing water system, a flow meter for a two-way freezing water return pipe, a water temperature sensor for a back-way freezing water return pipe of a freezing water pump, the water temperature sensor for a freezing water outlet pipe of an air conditioning mainframe, the water temperature sensor for a cooling water outlet pipe of the air conditioning mainframe and the water temperature sensor for a cooling water inlet main pipe of the air conditioning mainframe respectively collect pressure difference, flow speed and water temperature of the corresponding position; collection values are transferred into a fuzzy controller, the fuzzy controller gains dynamic flow and speed parameters through the control of a fuzzy prediction model and an optimal algorithm model, the dynamic flow and speed parameters are transferred into each electric saver, and the speed and the flow of corresponding fans and water pumps are controlled through the frequency change of the electric saver. The invention has the advantages of the high temperature-adjusting precision, the good dynamic performance, the small mechanical loss, the fully-automatic remote monitoring, the closed-loop control of temperature, the soft starting and stopping of a motor and the optimum system electricity-saving rate.

Owner:SUZHOU IRON TECH

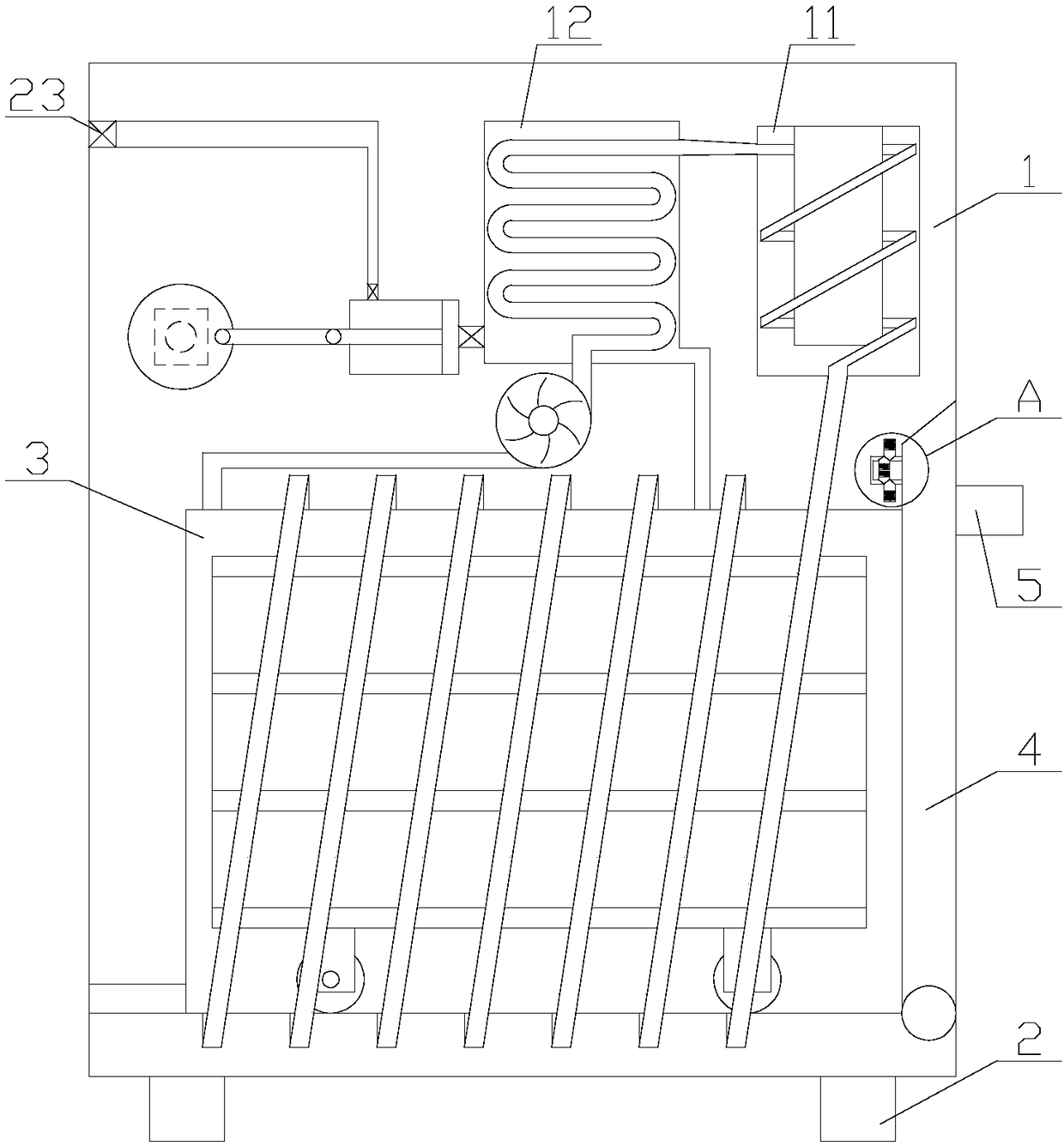

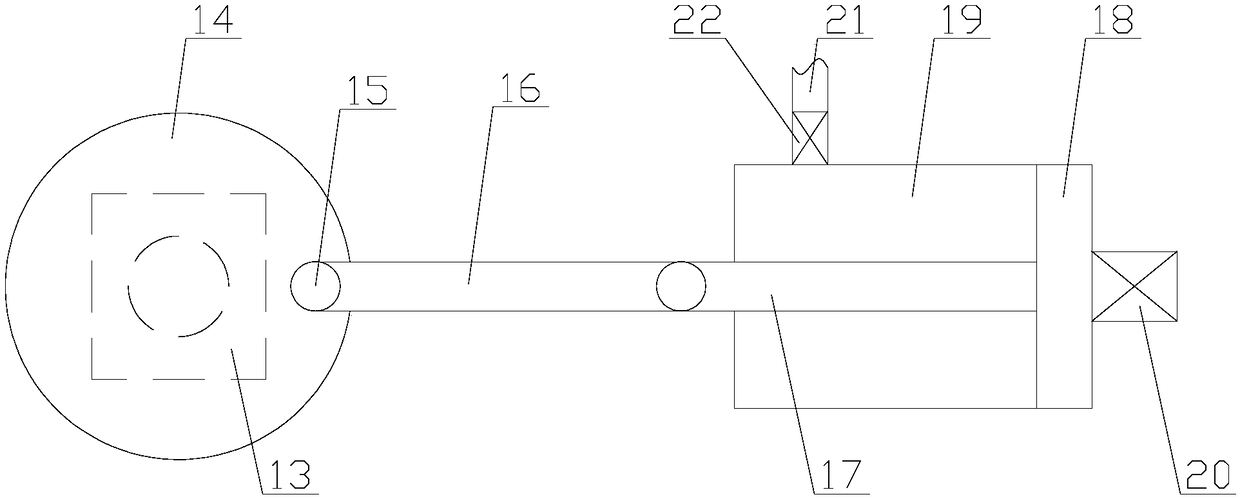

Continuous chocolate tempering machine

InactiveCN103583764AHigh temperature regulation accuracyAccurate and precise controlCocoaElectric machineryEngineering

The invention discloses a continuous chocolate tempering machine. The continuous chocolate tempering machine comprises a box body, a tempering center, a cold water and hot water circulation pipeline system, a motor, a syrup delivering pump and a heat preservation cylinder, wherein the motor is arranged on the top in the box body; the tempering center is a heat exchanger, is positioned right below the motor, and is formed by three layers of interlayer heat exchanging cylinders with clamping sleeves in a stacking manner, the two sides of each cylinder layer are respectively provided with water nozzles which are connected with the cold water and hot water circulation pipeline system, the heat exchanger is internally provided with a vertical type scraper blender, and the upper part and the bottom of the heat exchanger are respectively provided with a feed port and a discharge port; the heat preservation cylinder is positioned outside the box body, the syrup delivering pump is positioned on the upper part of the heat preservation cylinder and one end of the syrup delivering pump is connected with the heat preservation cylinder through a syrup transporting pipe, and the other end of the syrup transporting pipe is connected with the feed port arranged on the upper part of the heat exchanger. The continuous chocolate tempering machine provided by the invention has the advantages that the production capacity is large, the tempering precision is high, the tempering time is short, the slurry temperature uniformly before feeding is good and the like, the demolding of chocolate is guaranteed, the crystal quality is well stabilized, and the product quality is improved.

Owner:SUZHOU MAIKE FOOD MACHINERY PLASTIC CEMENT

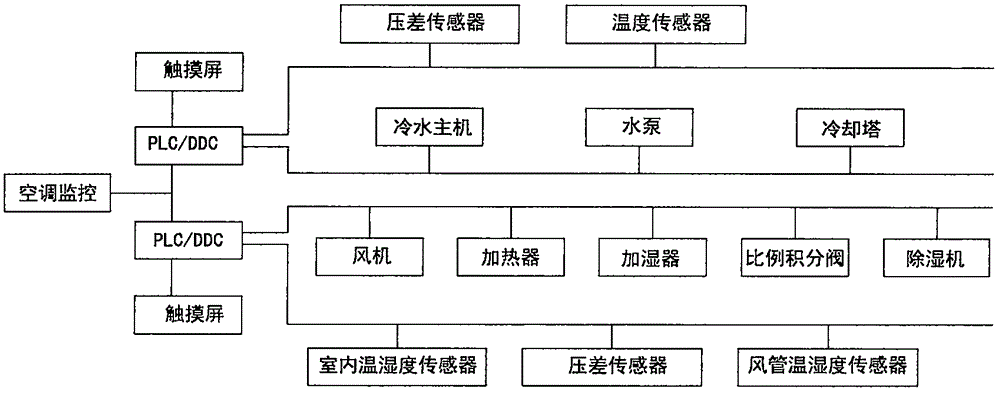

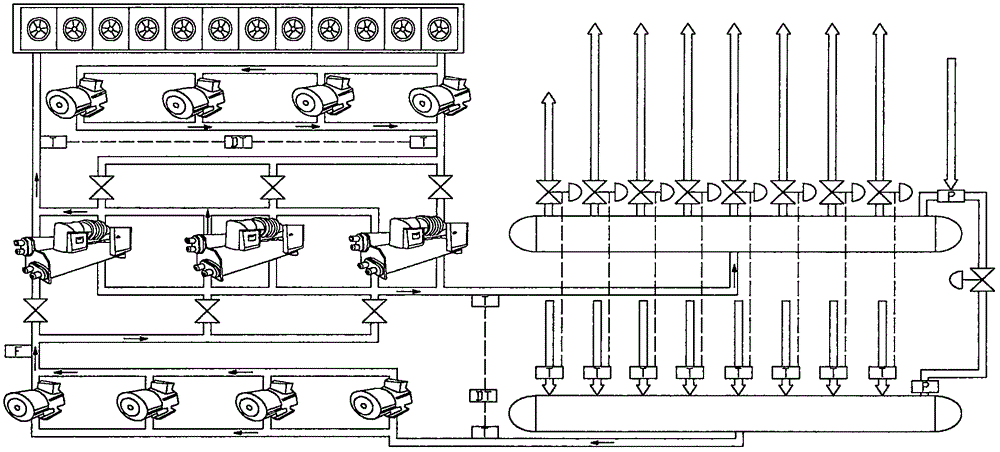

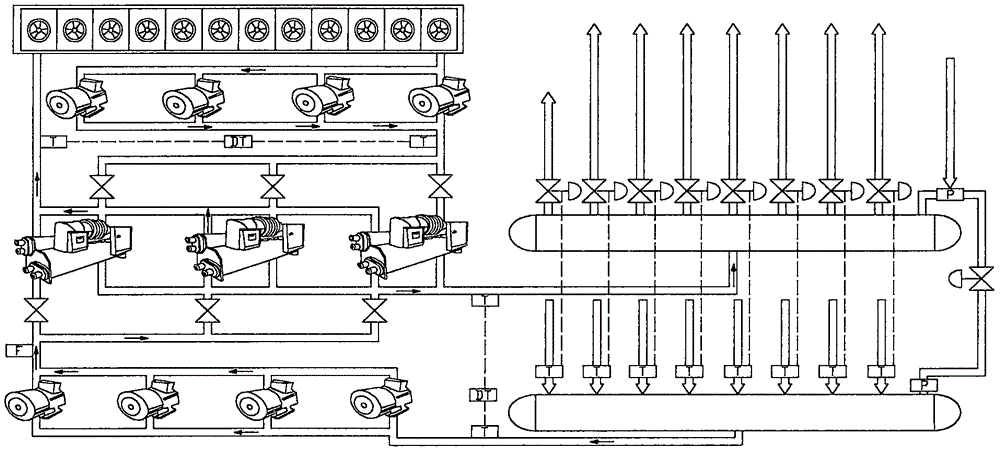

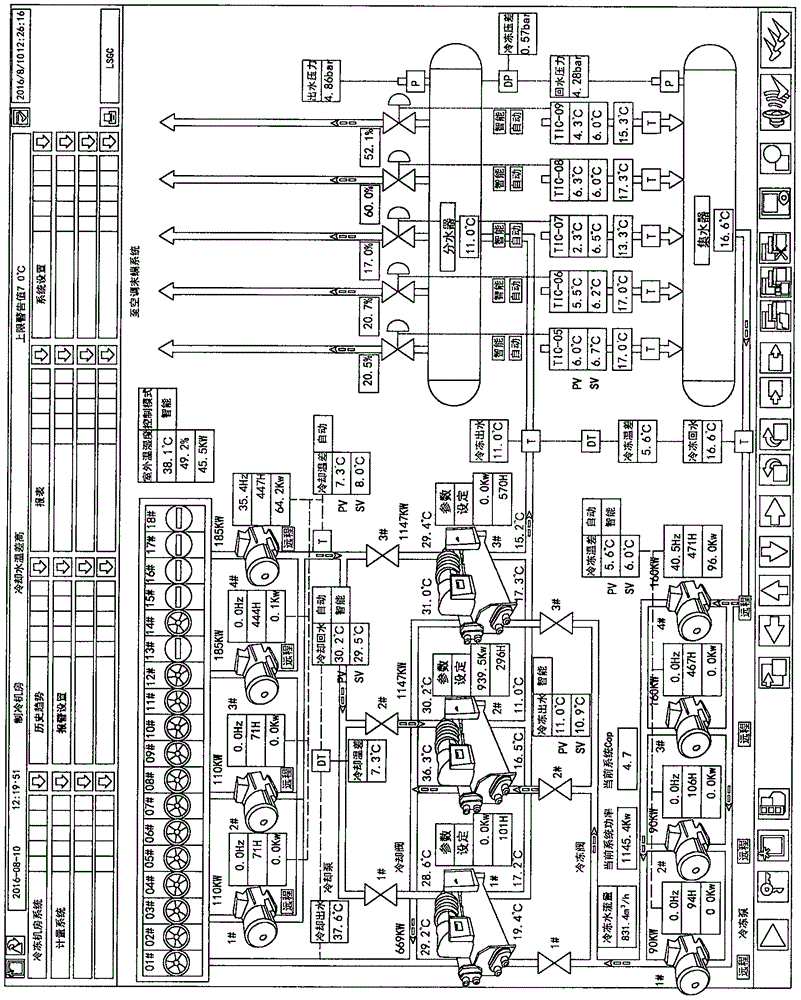

Control method for intelligent power saving of freezing pumps in central air conditioner monitoring system

InactiveCN106839275AHigh temperature regulation accuracyImprove dynamic performanceMechanical apparatusSpace heating and ventilation safety systemsLoop controlEngineering

The invention relates to a control method for intelligent power saving of freezing pumps in a central air conditioner monitoring system. According to the control method, the technical problem that deficiency exists in design of a control method for intelligent power saving of freezing pumps in an existing central air conditioner monitoring system is solved. According to the main points of the control method for intelligent power saving of the freezing pumps in the central air conditioner monitoring system, when load of the tail end of a central air conditioner is changed, the water supply and return temperature, the temperature difference, the pressure difference and the flow of a water system are also changed along with the load; detected parameters are sent to an intelligent power saving managing device by a flow gauge, a pressure difference sensor and a temperature sensor, according to the collected real-time data and system historical data, based on the principles that frequency conversion water pump efficiency is highest, and frequency conversion water pump total power consumption is lowest, the intelligent power saving managing device automatically adjusts the running number and frequency of the freezing pumps; and the frequency is adjusted according to the advanced composite loop control algorithm that the temperature serves as an outer loop, and the pressure difference serves as an inner loop, and the temperature difference set value is adjusted and optimized in a dynamic mode according to balancing of supply and demand of a tail end cooling capacity, so that acting of the freezing pumps is controlled, the freeze water flow is changed, and output energy of the system is matched with a tail end load demand.

Owner:杭州裕达自动化科技有限公司

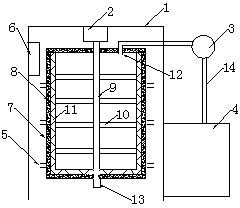

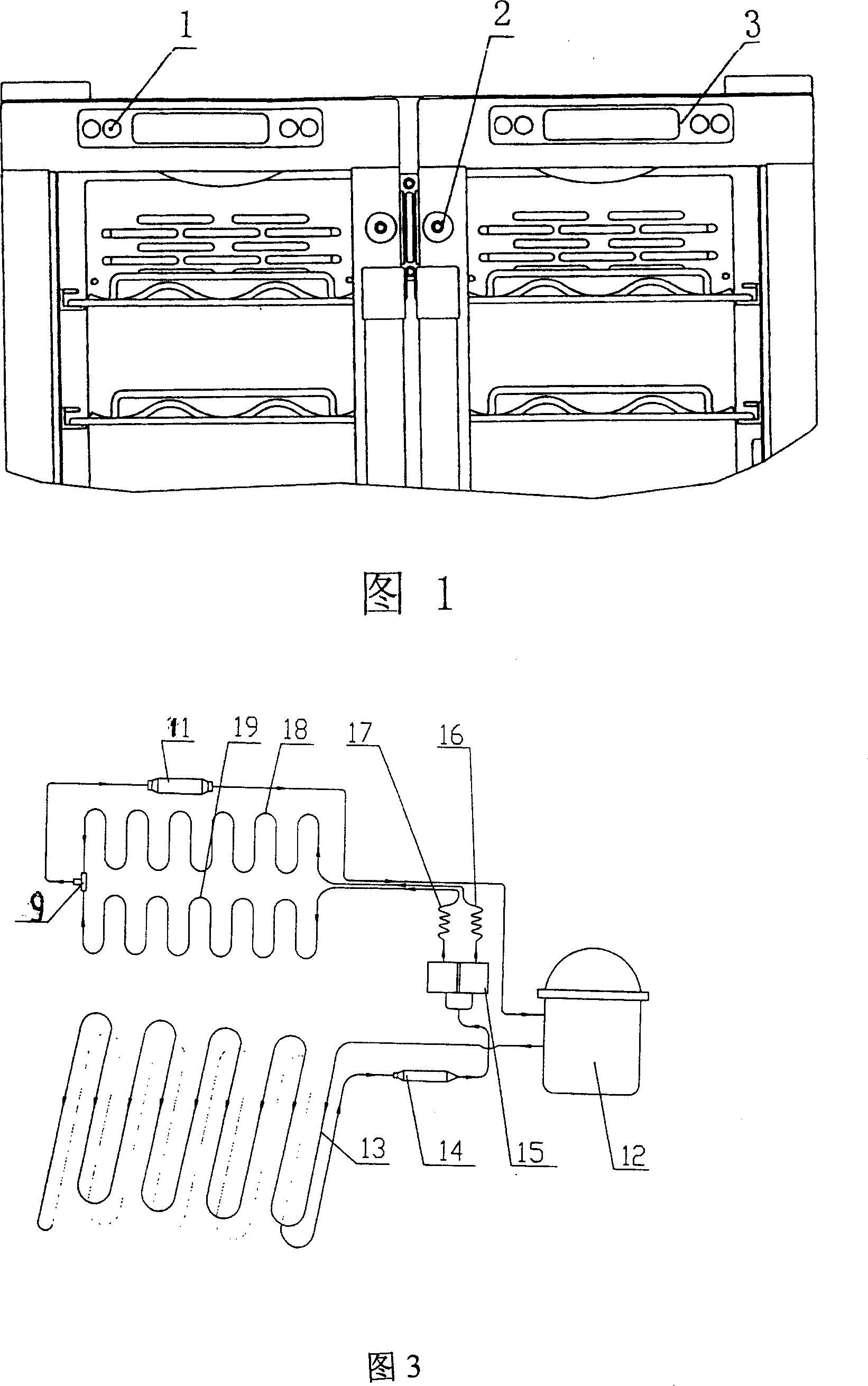

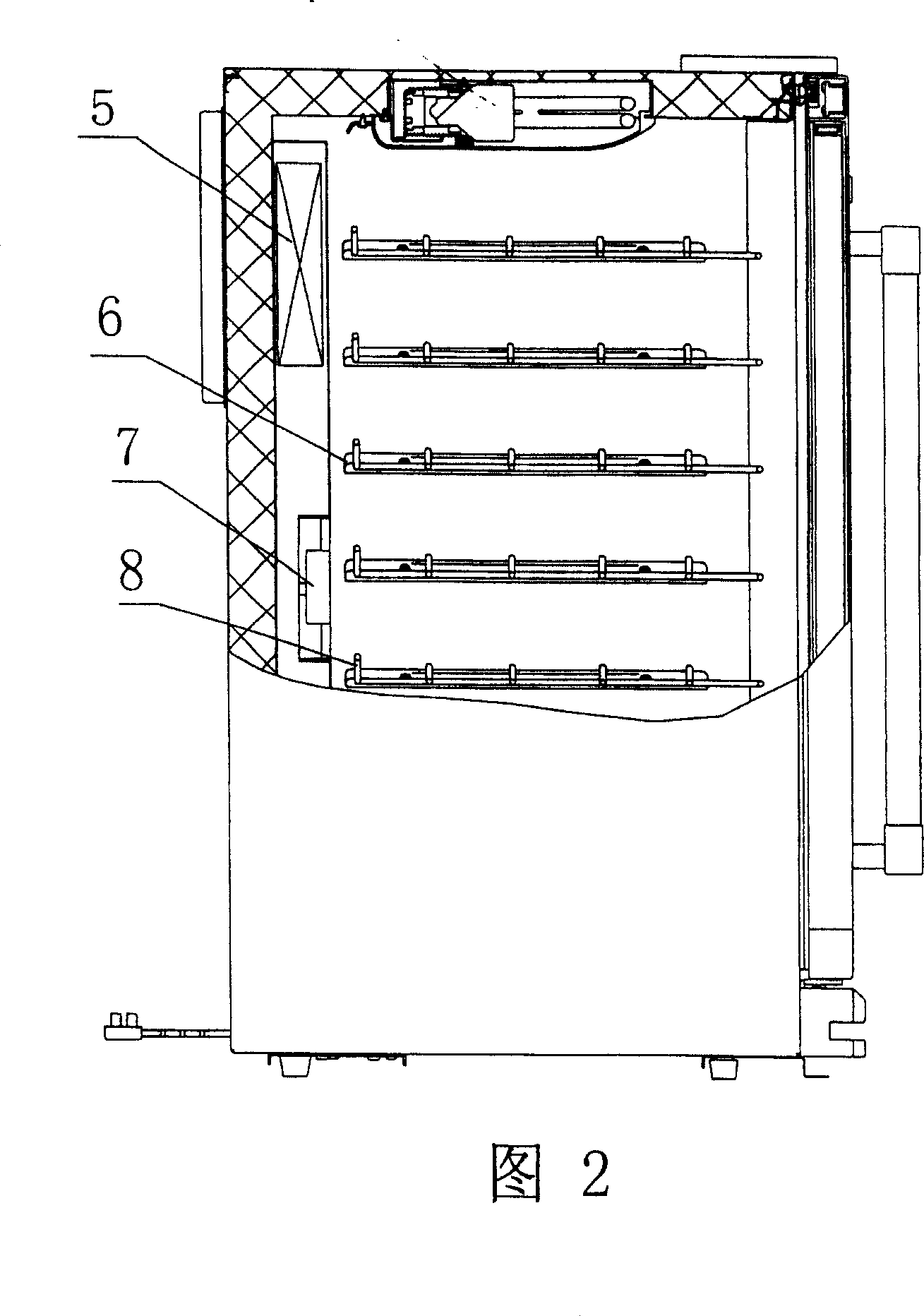

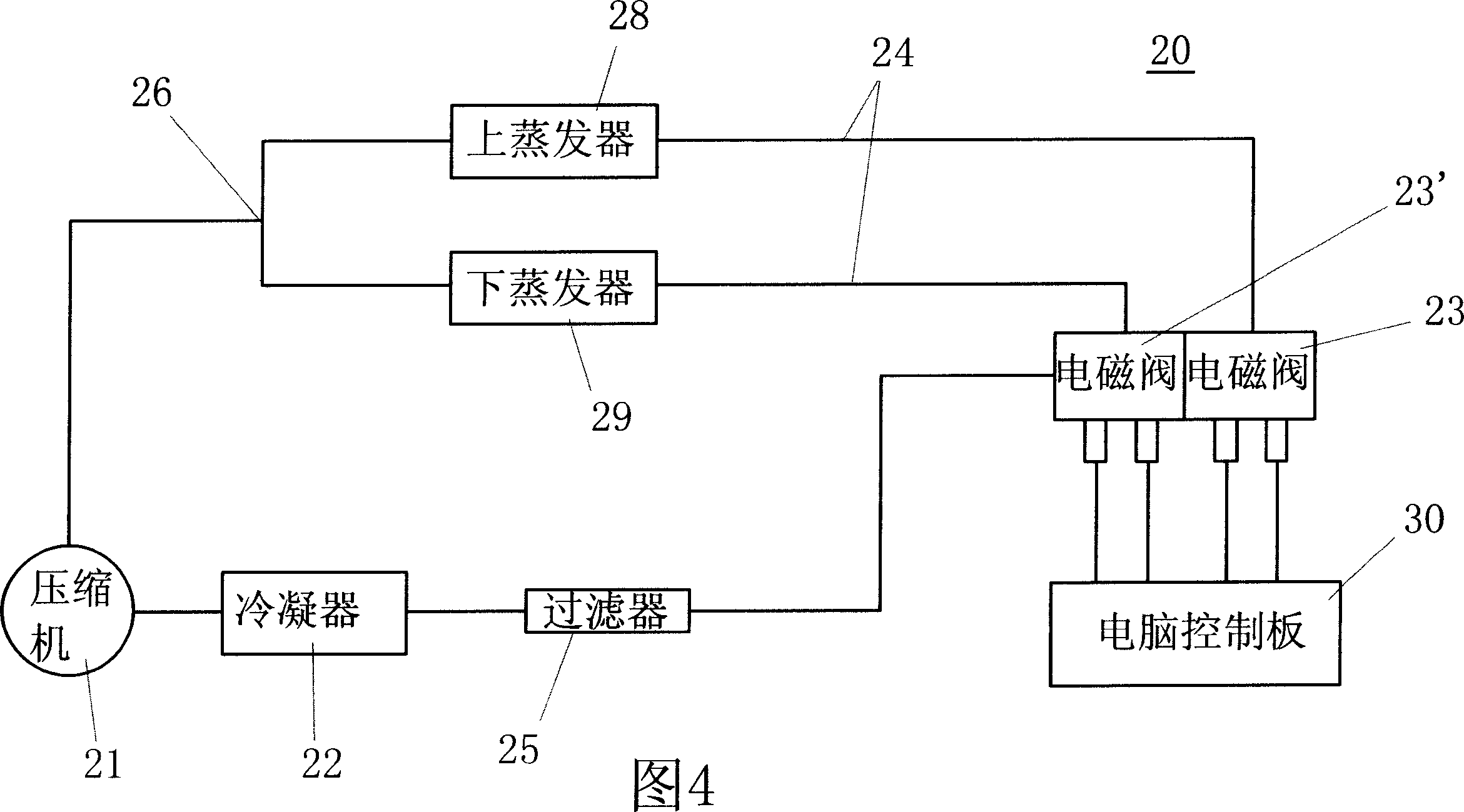

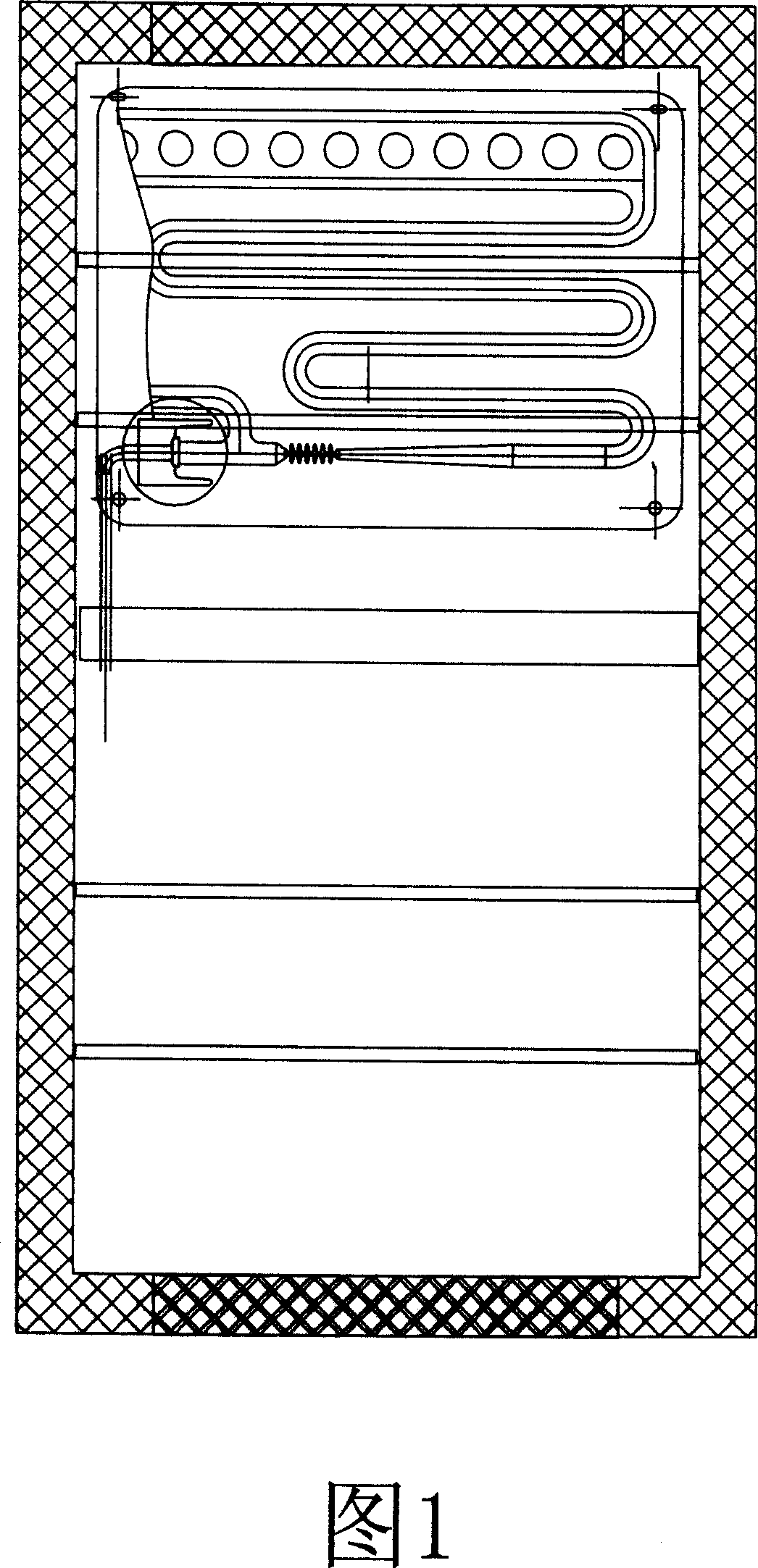

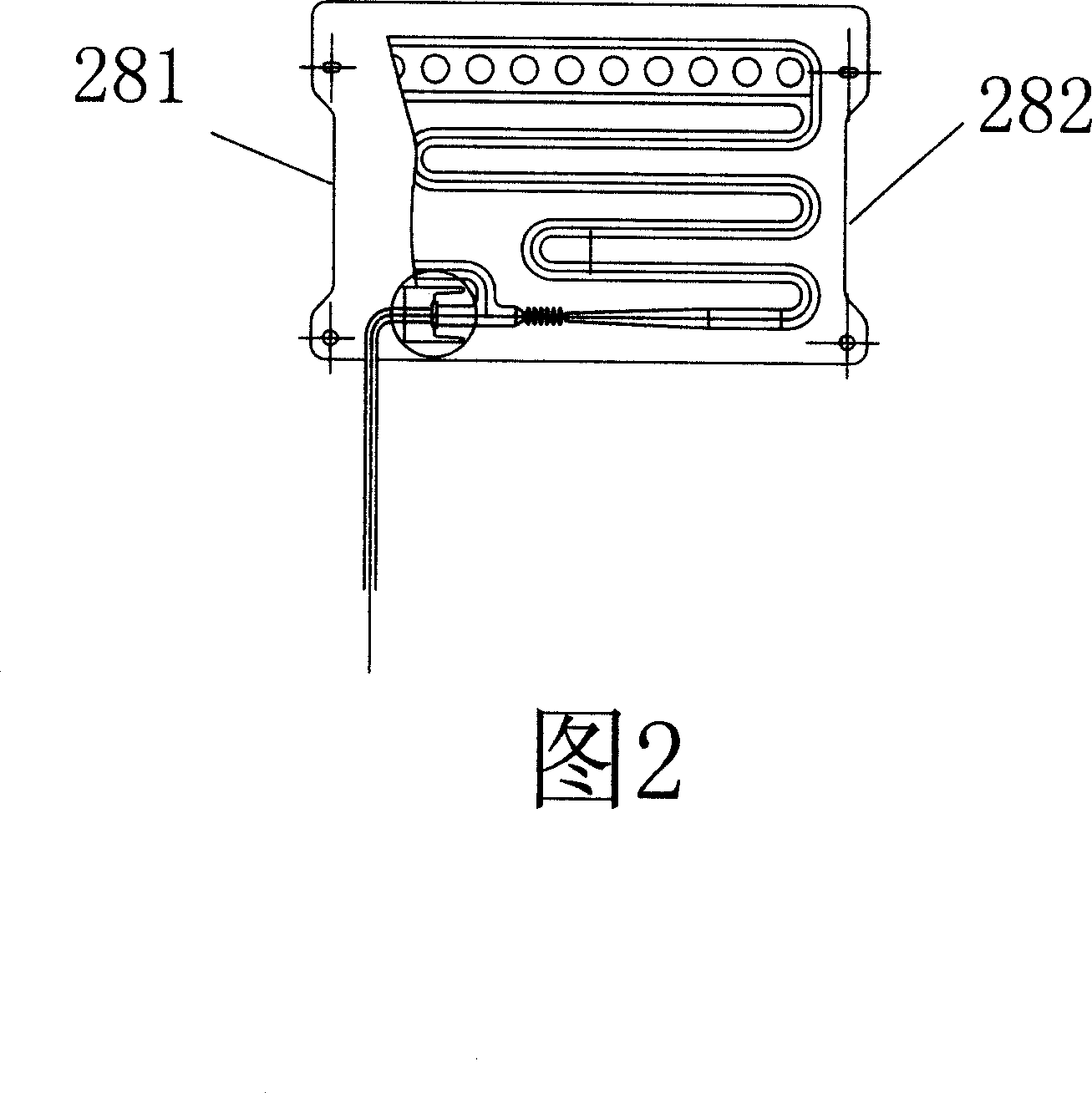

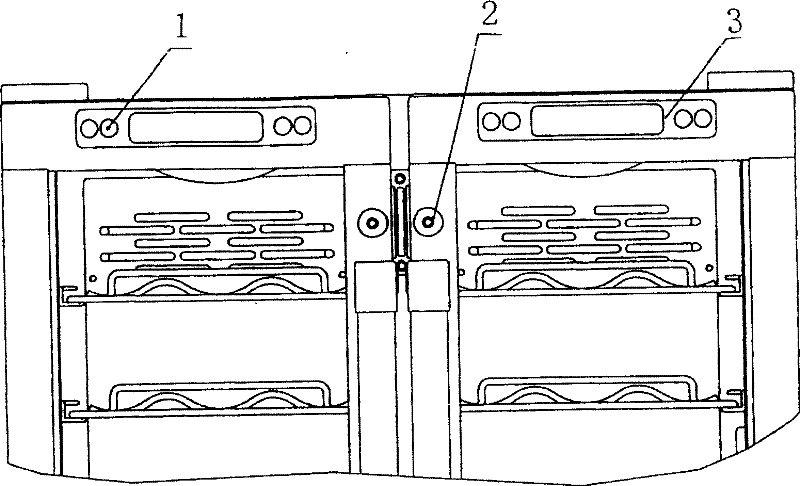

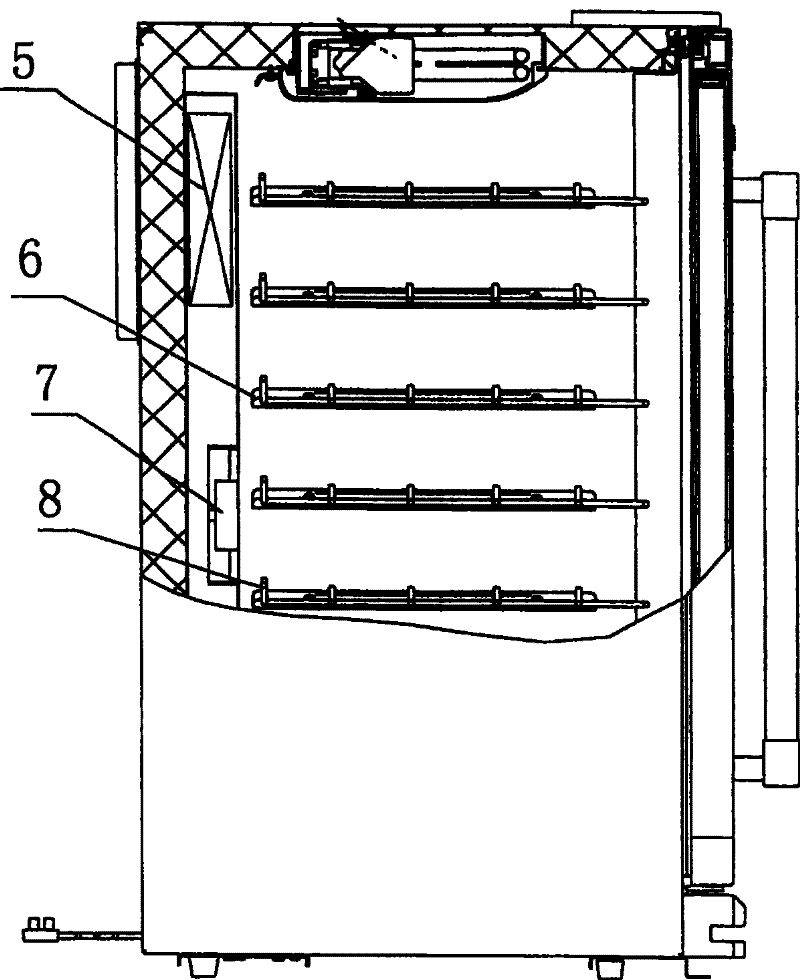

Double temperature double control wine cabinet and method for enhancing accuracy of temperature control

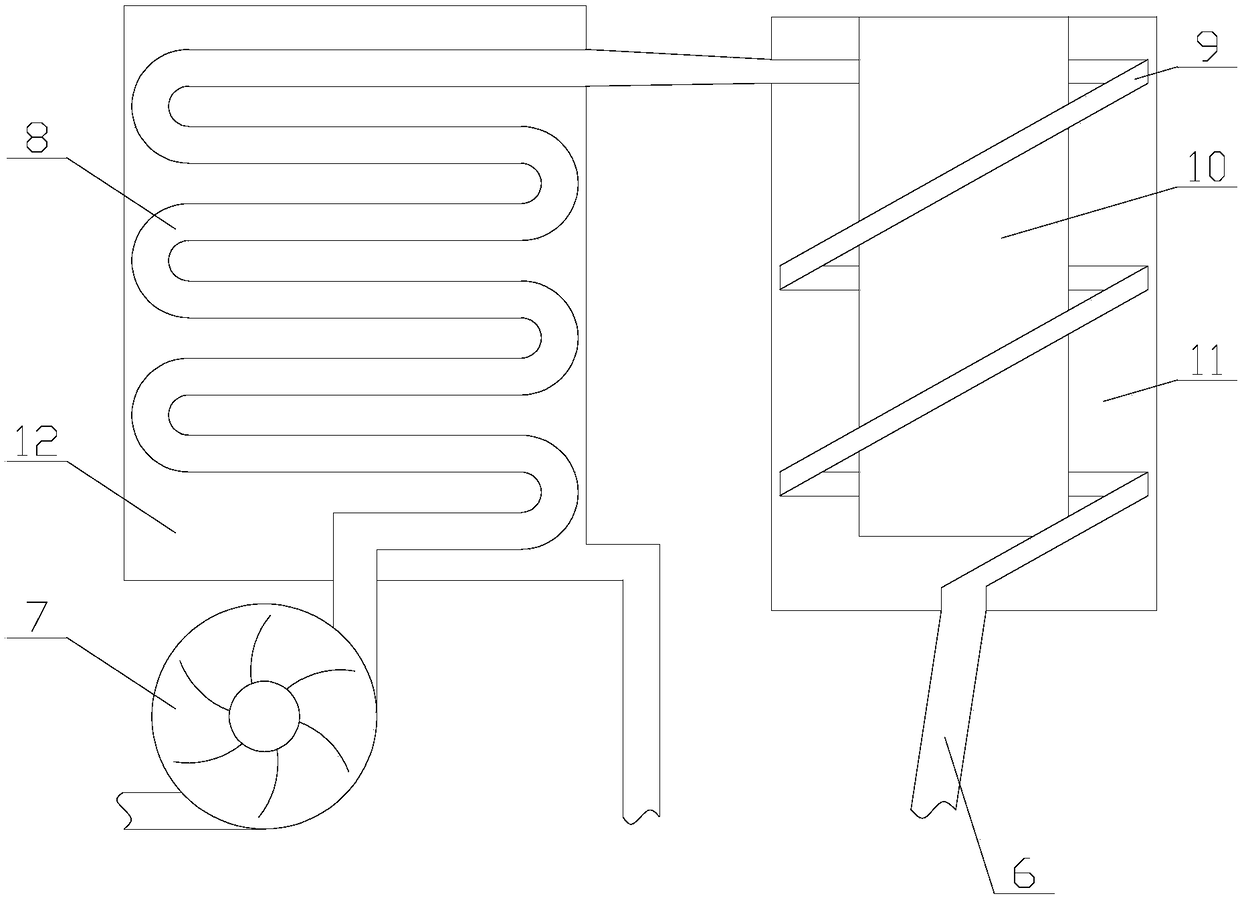

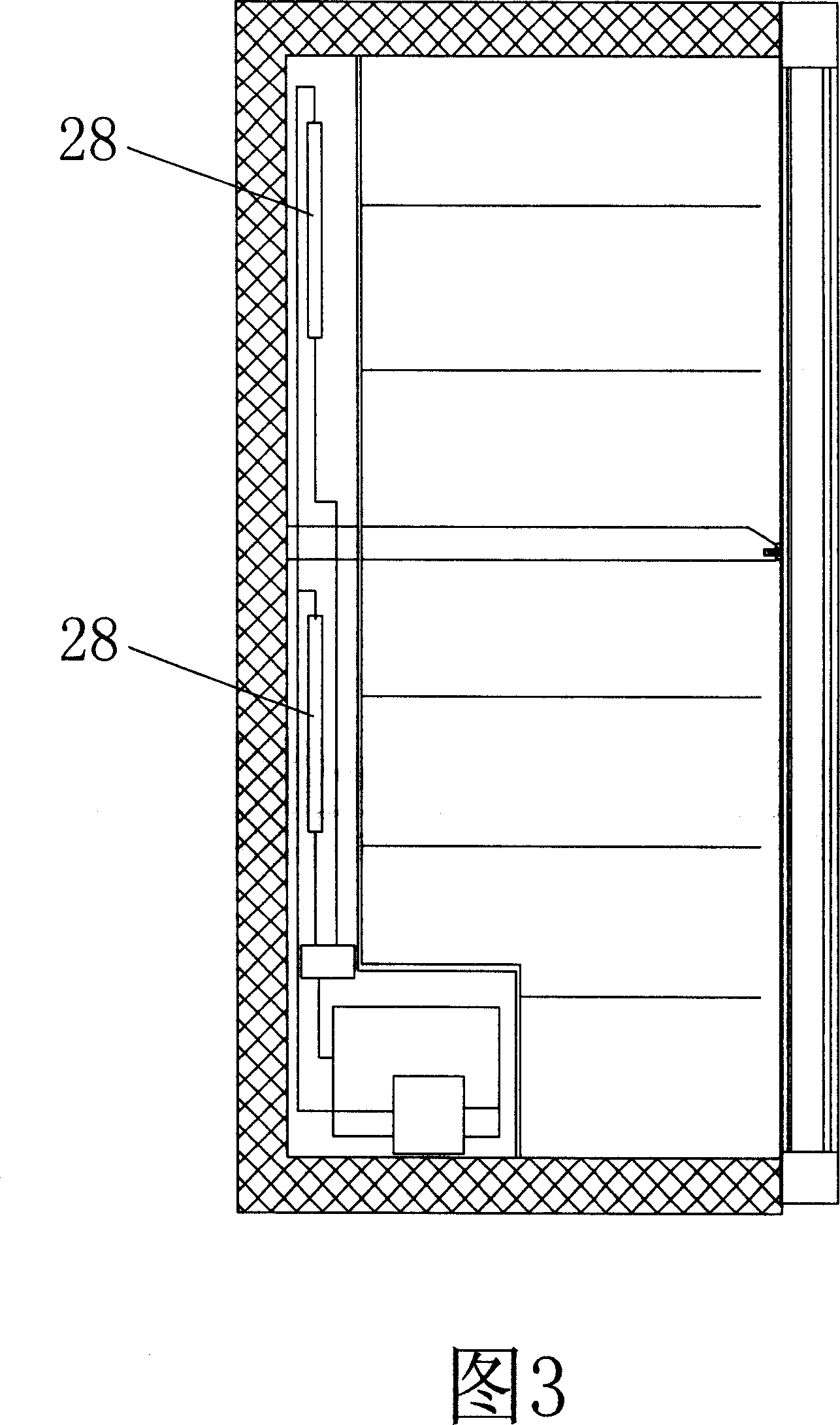

ActiveCN101097108ABeautiful shapeSmall footprintLighting and heating apparatusDomestic refrigeratorsTemperature controlComputer control system

The invention discloses a double temperature and double controlling sideboard of high temperature controlled accuracy, which is characterized by the following: comprising box body, cooling system and computer controlled system; cascading compressor, condenser, magnetic valve, capillary tube and evaporator as cooling system; combining to one way through pipe tee; turning to compressor; cascading to a closed loop circuit; separating the inner of the box body to upper and lower cold room; setting the evaporator of the cooling system as two; arranging in the upper and lower cold room; connecting the two evaporator to the condenser through own magnetic valve. This invention possesses nice shape and small accommodation area.

Owner:HAIER GRP CORP +1

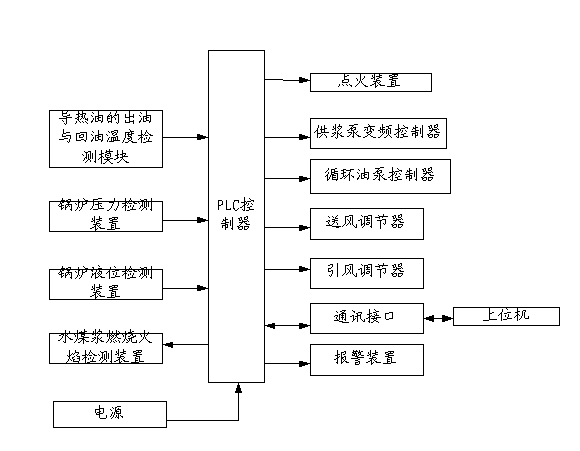

Control system for water-coal-slurry heat-conducting oil boiler

InactiveCN103307756AAutomatic control adjustment sensitiveFulfil requirementsFluid heatersPolyesterHuman–machine interface

The invention belongs to the technical field of boiler control and particularly relates to a control system for a water-coal-slurry heat-conducting oil boiler. The control system comprises a PLC (Programmable Logic Controller) with a built-in control procedure; the signal acquisition input end of the PLC is connected with an oil outlet and oil return temperature detection module of heat-conducting oil, a boiler pressure detection device, a boiler liquid level detection device and a coal-water slurry combustion flame detection device; the control output end of the PLC is connected with an induced air regulator for controlling an induced draft fan, an air supply regulator for controlling an air feeder, a circulating oil pump controller, a slurry supply pump variable-frequency controller and an ignition device; and the PLC is also connected with a human-computer interface and an alarm interlock control device. The control system has the benefits that the water-coal-slurry boiler is controlled by the PLC to perform stable heating and accurately adjust the temperature; automatic temperature control and regulation is sensitive, the temperature regulation precision is high, and the heat supply is stable; and the outlet temperature of the heat-conducting oil boiler is controlled to be plus or minus 1 DEG C, so that the requirements of a polyester production enterprise and other enterprises are better satisfied.

Owner:QINGDAO CLEAR NEW ENERGY

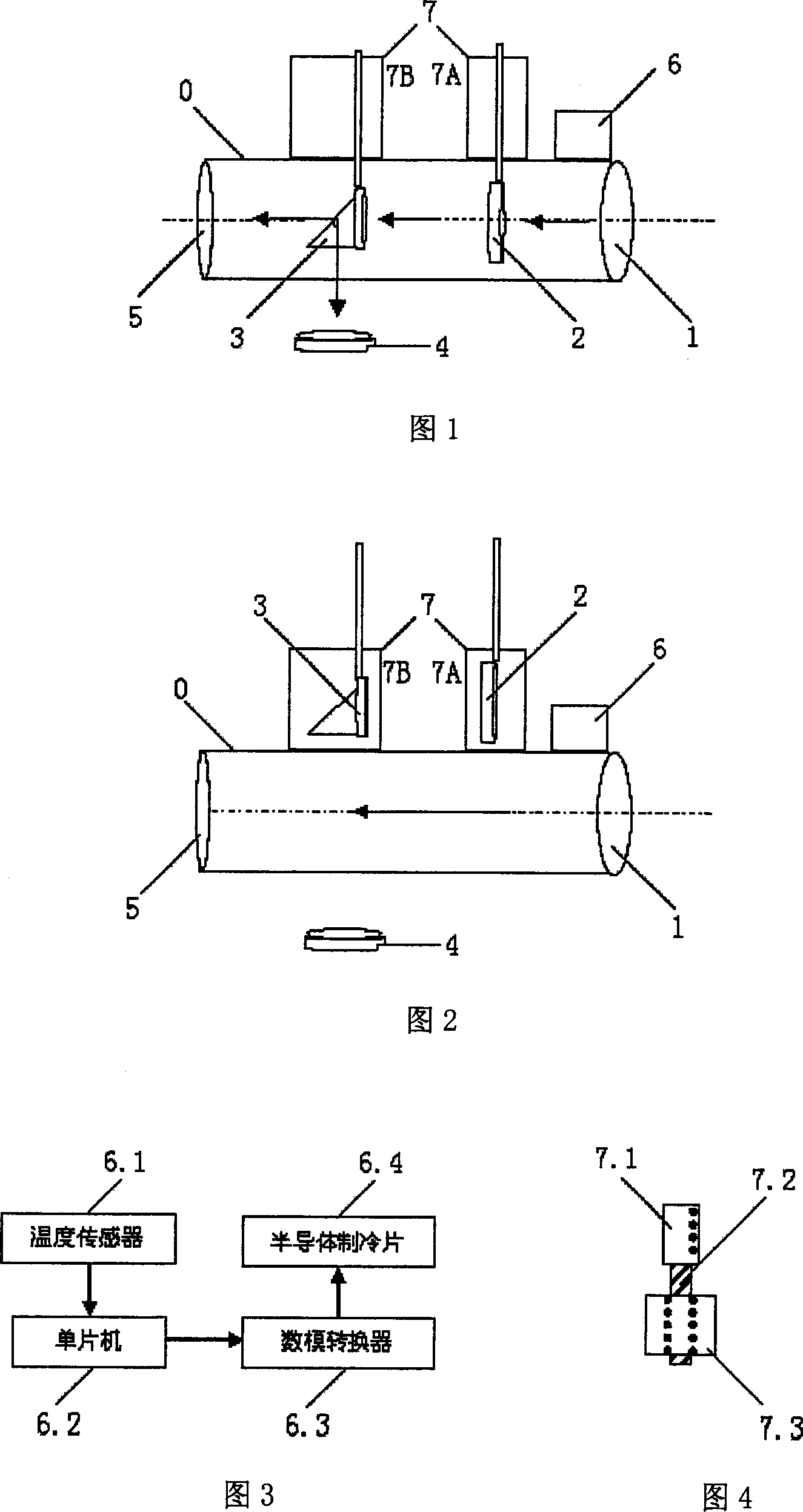

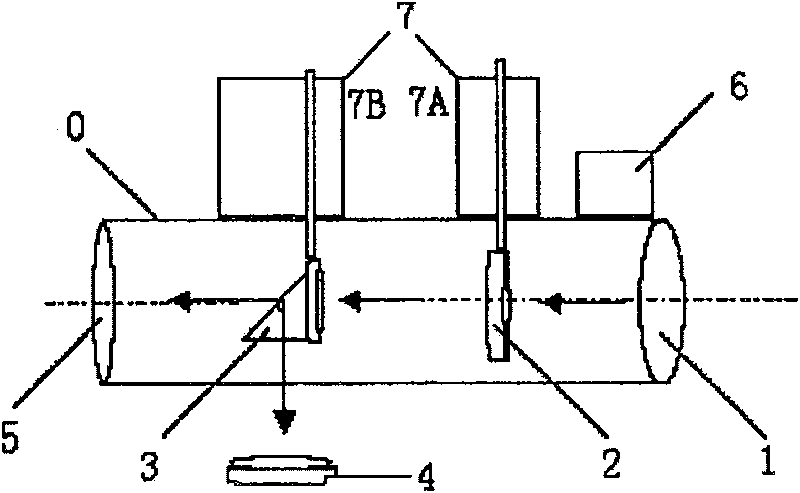

Comprehensive low-noise constant-temperature laser receiving system

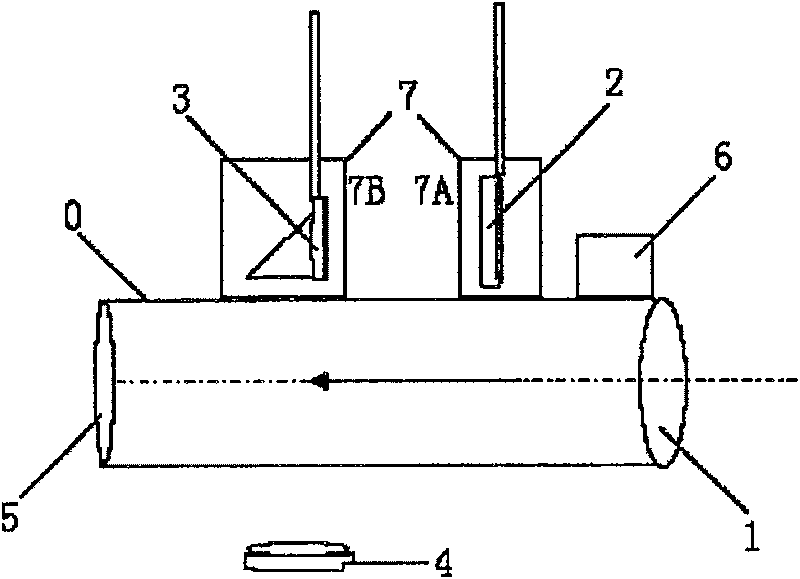

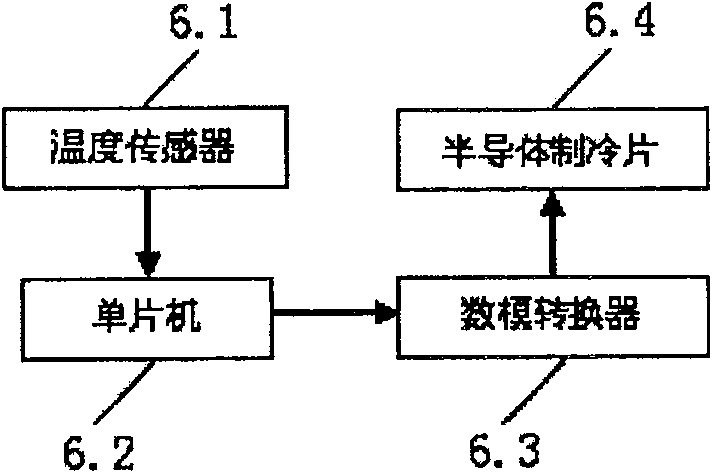

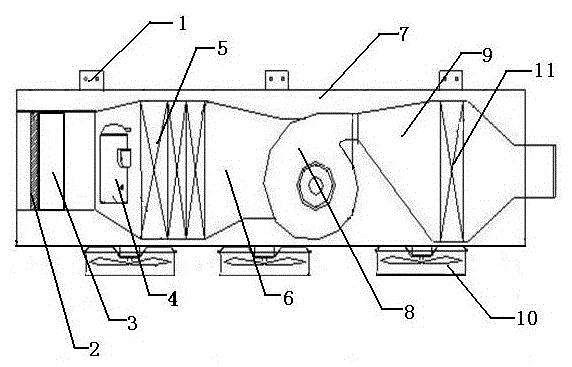

ActiveCN1936617AHigh temperature regulation accuracyEasy to switchElectromagnetic wave reradiationOptical elementsThermoregulatory systemLight filter

The invention discloses a laser receiver system of low yawp and constant temperature. The collimating lens (1), the light filter (2), the angle reflector (3), the photoelectric receiver (5) are set in the cylinder (0) from the right to the left. The CCD (4), the temperature adjustment system (6) and the transmission gear (7) are set on the top of the cylinder; the transmission gear (7) includes the first transmission gear (7A) and the second transmission gear (7B); the light filter (2) is connected to the first transmission gear and the reflector (3) is connected to the second transmission gear (7B); the position of the CCD is correspond to the angle reflector (3). The invention has the function of constant temperature, light filter and light tine adjustment. So it can be used for the lidar, the satellite laser ranging, the spacecraft tracking, the stellar tracking observation and the space fragment dynamic tracking.

Owner:INST OF EARTHQUAKE CHINA EARTHQUAKE ADMINISTRATION

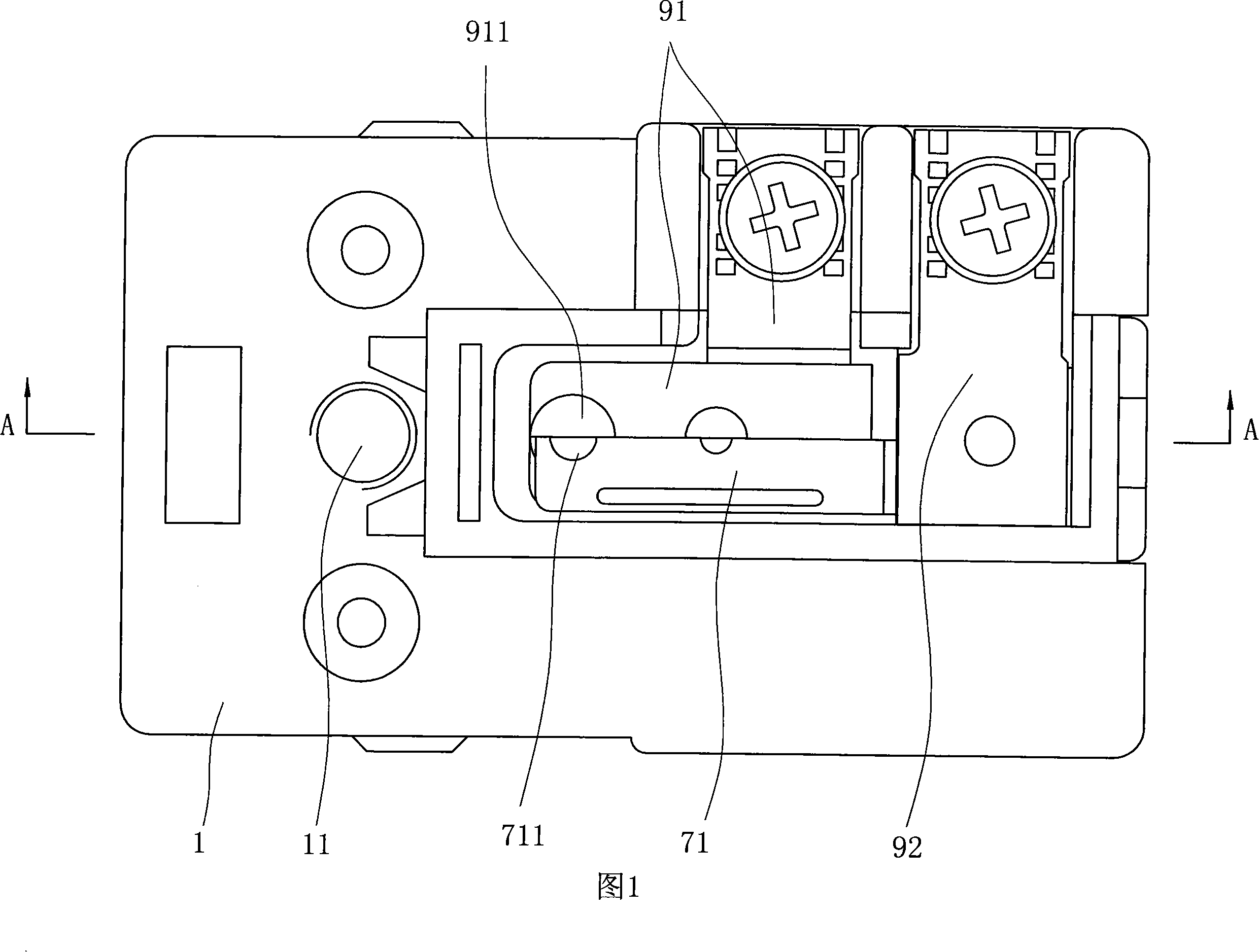

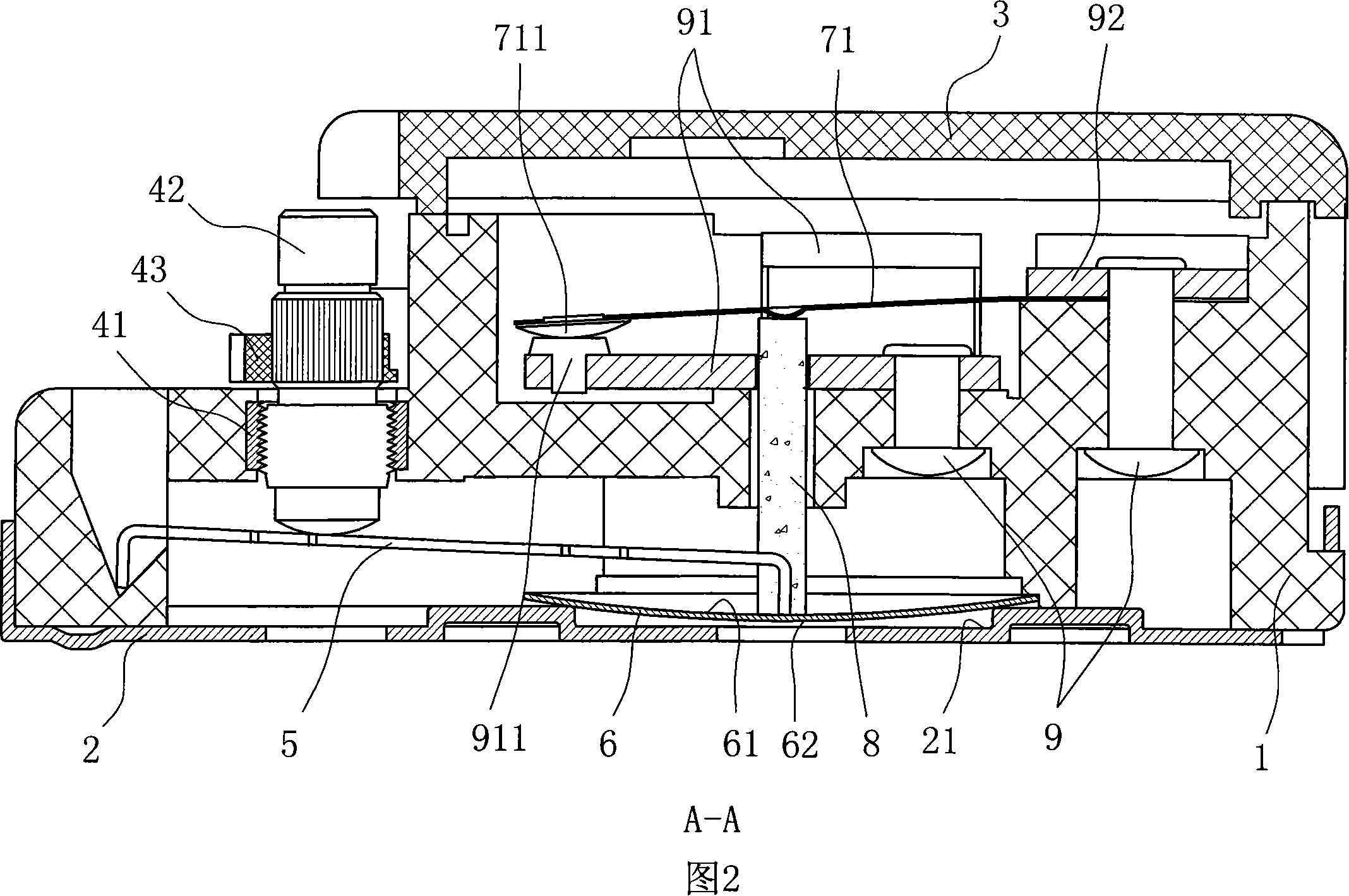

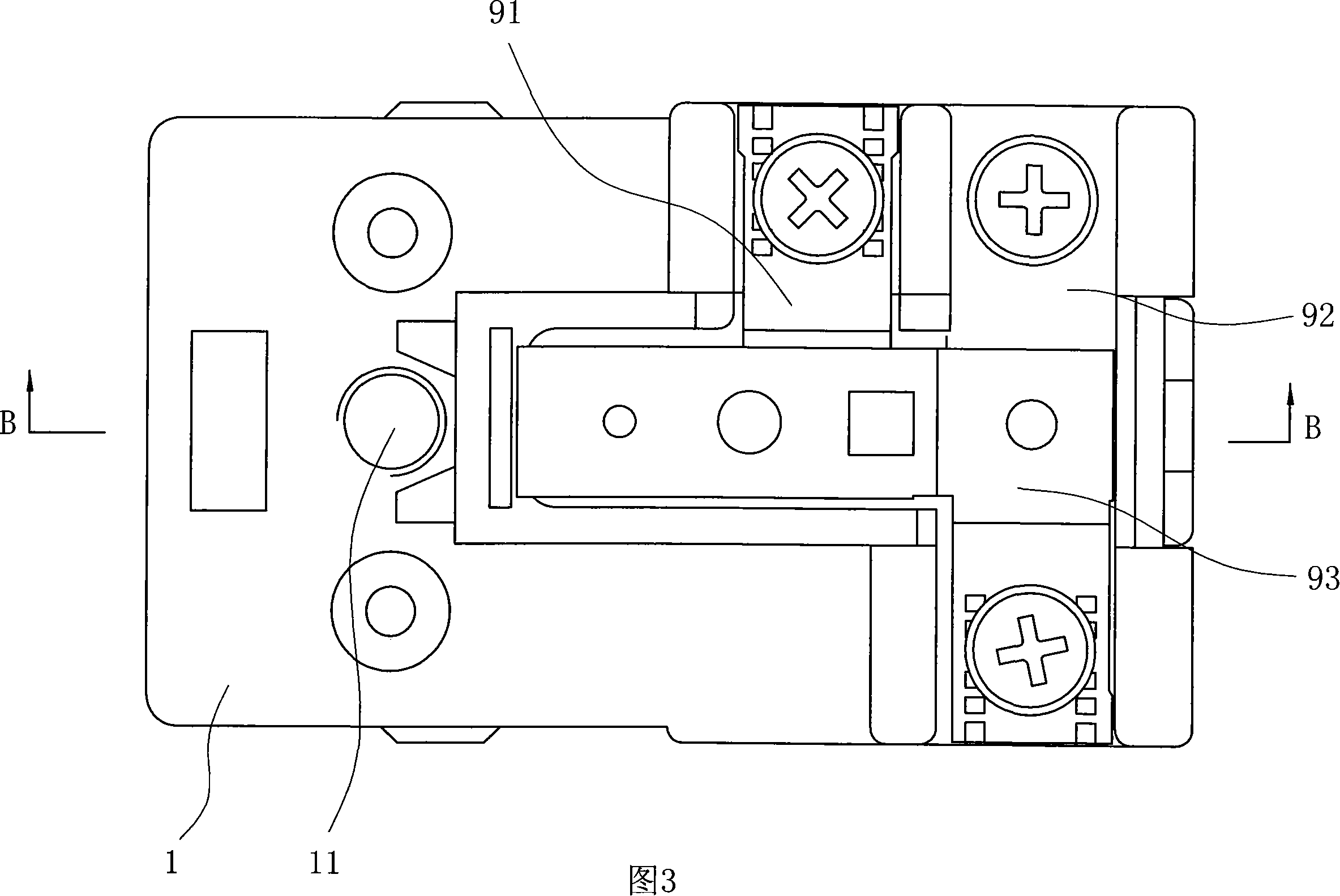

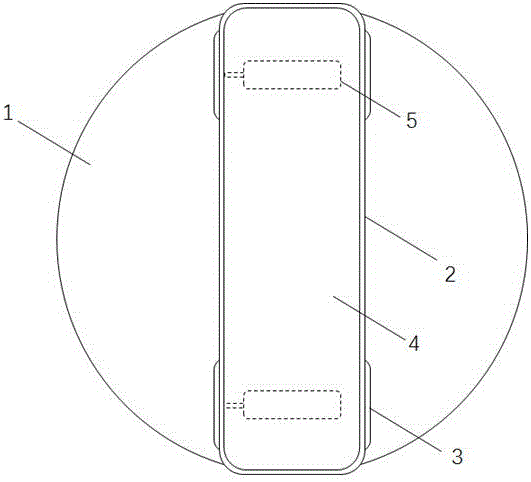

Adjusting temperature controller

InactiveCN101216713AHigh precisionLarge carrying working currentTemperature control without auxillary powerEngineeringThermostat

An adjustable thermostat comprises a shell (1) with a through hole (11), a temperature adjusting device with an adjusting screw (42) which is arranged in the through hole (11) and a link gear which is provided with a bimetallic strip (6) as a temperature sensing element. The adjustable thermostat is characterized in that the through hole (11) is provided with a metal nut (41) which matches with the adjusting screw (42) and an elastic temperature adjusting piece (5) which counterbalances the adjusting screw (42) at the tail; one end of the temperature adjusting piece (5) is fixed on the shell (1), and the other end is a moveable end which counterbalances the inner part of the central bending surface of the bimetallic strip (6). The invention applies pressure on the bimetallic strip via the temperature adjusting piece, and no current passes through the temperature adjusting piece so that no softening results; thereby improving the adjustment precision; a copper nut is embedded and fixed in the shell during the process of molding the shell, so that the cooper nut is integral with the shell and metal threads thereof are not prone to abrasion, thereby improving the service life of the product.

Owner:朱英年

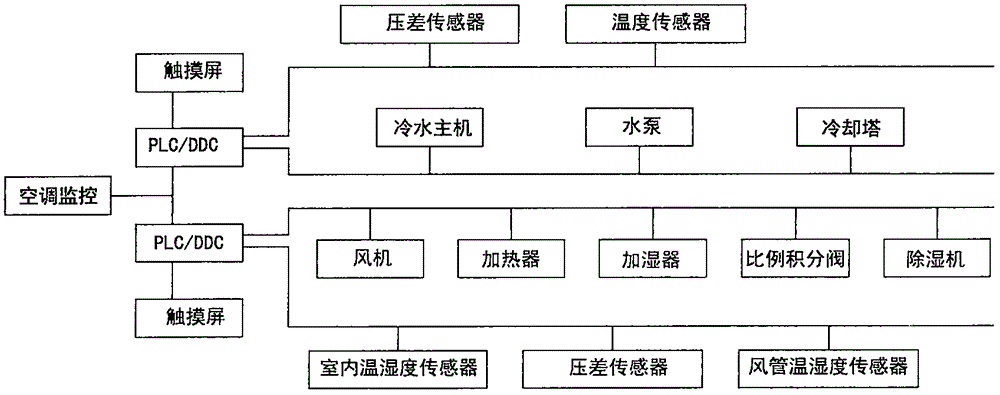

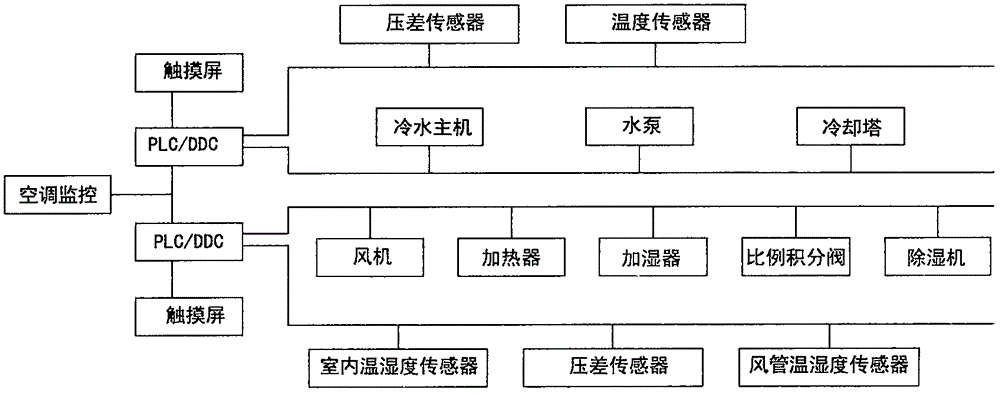

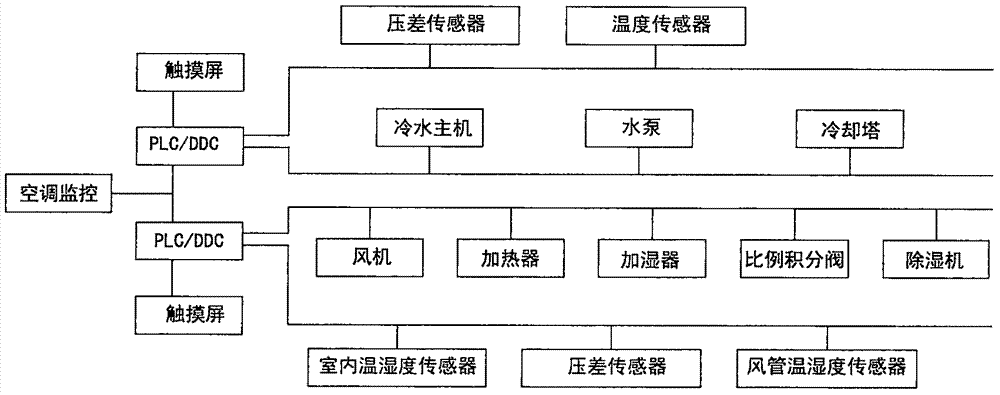

Control method for building supervisor in central air-conditioning monitoring system

InactiveCN106813359AHigh temperature regulation accuracyImprove dynamic performanceMechanical apparatusSpace heating and ventilation safety systemsAutomatic controlControl manner

The invention relates to a control method for a building supervisor in a central air-conditioning monitoring system, and the control method is designed for solving the technical problem that a control method for a building supervisor in an existing central air-conditioning monitoring system has defects. The key point is that the central air-conditioning monitoring system for the control method is equipped with a navigation chart or an overview chart, and is further equipped with a broadcast group-sending function and a broadcast single-sending function of a fan coiled pipe, wherein the navigation chart or the overview chart is used for displaying fan coiled pipe data of each area of each floor; a temperature controller is connected with the central air-conditioning monitoring system through a 485 communication bus protocol; an operation panel of the temperature controller is set with an on-off control mode, a winter-summer mode, a control mode, an unlocking mode, a broadcasting mode, an on-off effective mode, a winter-summer effective mode as well as a set temperature, a set upper limit temperature, a set lower limit temperature, a high grade, a middle grade, a low grade, a mode, unlocking, temperature and temperature limitation; and all of the equipment is started, the operation panel of the temperature controller is switched to a heating mode to operate in an unlocking state, the mode is automatically controlled, and a room temperature, the upper limit temperature and the lower limit temperature are set.

Owner:杭州裕达自动化科技有限公司

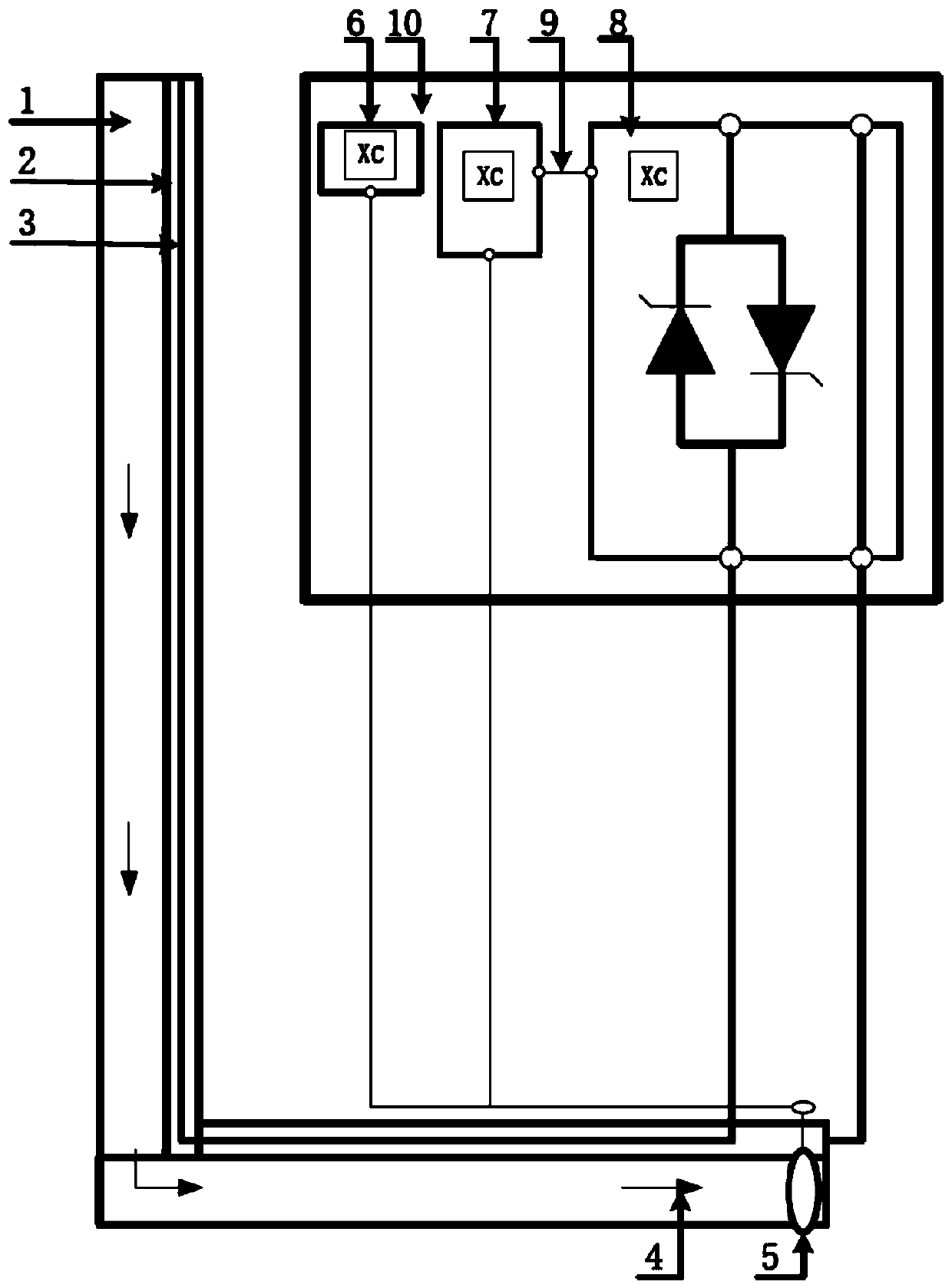

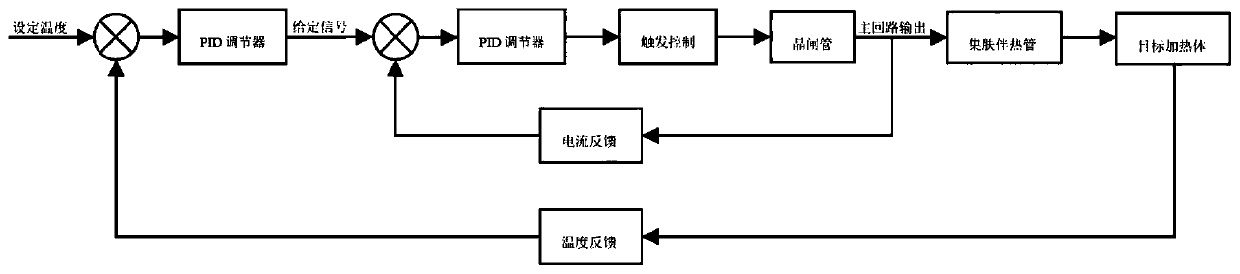

Constant temperature control method and constant temperature control system for power frequency skin-effect tracing system

InactiveCN110609580AReduce the number of on and offReduce shockAuxillary controllers with auxillary heating devicesPower controllerTemperature control

The invention discloses a constant temperature control method and constant temperature control system for a power frequency skin-effect tracing system and belongs to the field of control on the powerfrequency skin-effect tracing system. A temperature difference value between current temperature and a set temperature target can be calculated through collecting the current temperature of a target heating body at an outlet of a liquid transport tube in a timing manner, and output of a power controller is obtained through PID calculation according to the obtained current temperature difference value. According to the constant temperature control method, the temperature difference value between the current temperature and the set temperature target is calculated through timing collection, andoutput values of the power controller at different times are obtained through PID calculation by using the obtained current temperature difference value, so that output power can be timely adjusted according to the temperature of the target heating body, the number of on / off times of a heating power supply is reduced, the impact on a power supply transformer and load is reduced and the service life of the system is prolonged; and furthermore, skin-effect tracing output current is adjusted and controlled through PID calculation, so that the target heating body can be kept within a set range andthe control accuracy can be ensured.

Owner:西安西驰电气股份有限公司

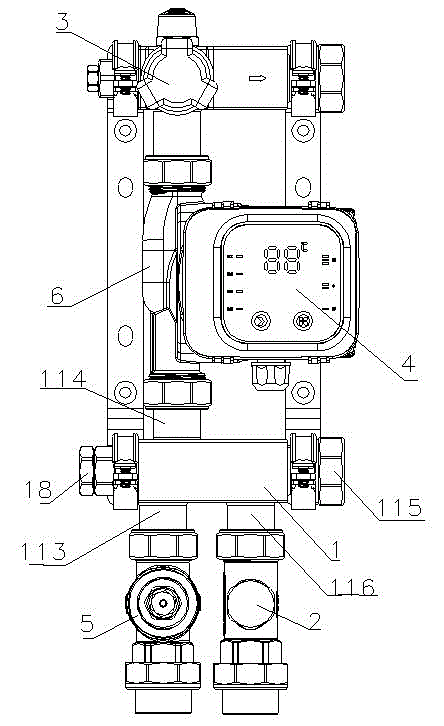

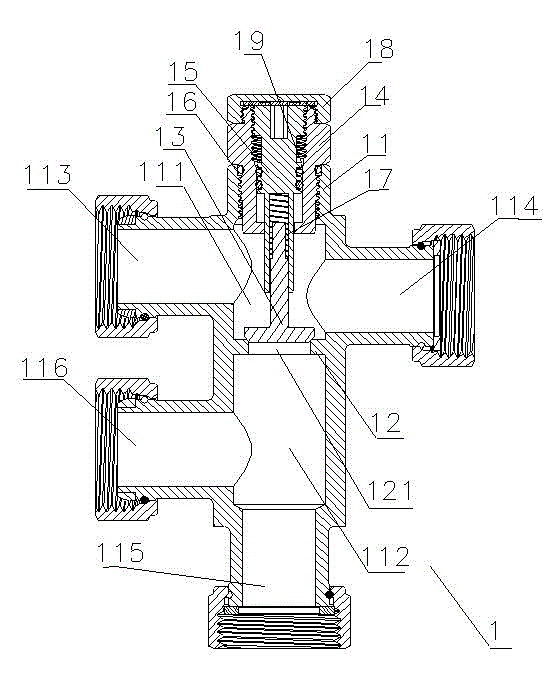

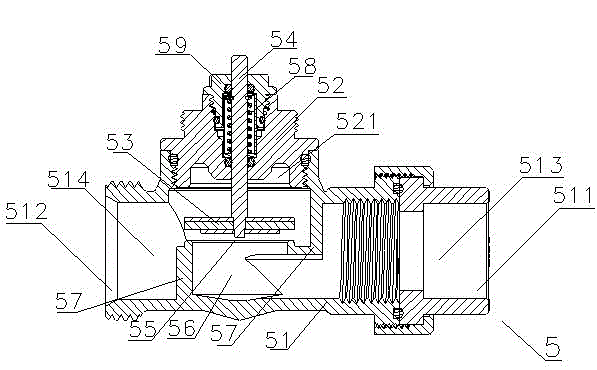

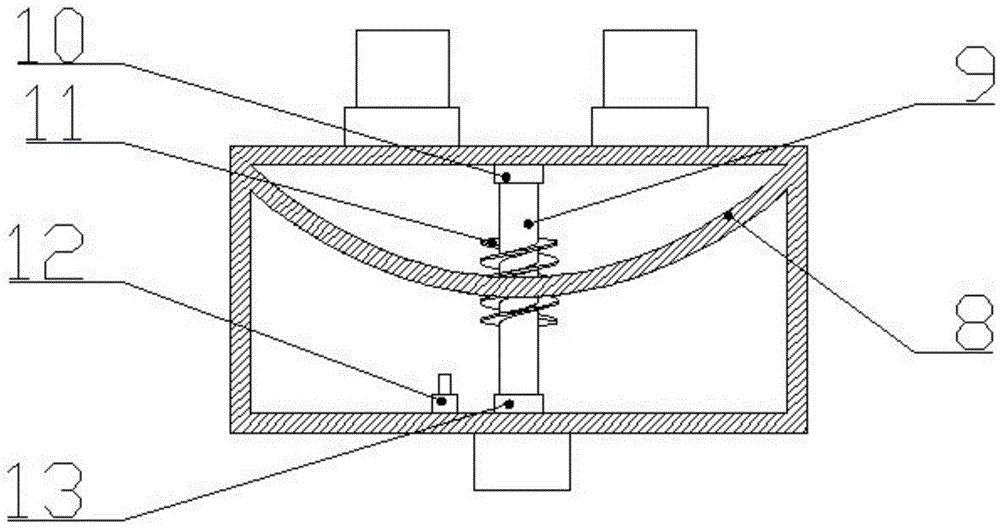

Water mixing device for floor heating

ActiveCN102878324ASimple structureControl mixOperating means/releasing devices for valvesMultiple way valvesEngineering

The invention discloses a water mixing device for floor heating. The water mixing device for floor heating comprises a water mixing valve which comprises a water mixing valve body and an adjustable non-return device, the water mixing valve body is a columnar hollow pipe, and the adjustable non-return device comprises a partition and an adjusting mechanism. The partition is arranged in the water mixing valve body to partition the water mixing valve body into a first cavity and a second cavity, and is provided with a water through hole. The adjusting device is provided with an adjusting valve core, and the adjusting valve core is positioned on one side of the first cavity and matched with the water through hole to adjust volume of water passing through the water through hole. The water mixing valve body is provided with a high-temperature water inlet, a mixed water outlet, a low-temperature water inlet and a low-temperature water return port, the high-temperature water inlet and the mixed water outlet are respectively communicated with the first cavity, and the low-temperature water inlet and the low-temperature water return port are respectively communicated with the second cavity. By the aid of the water mixing device for floor heating, the technical problem of complex structure of water mixing devices for floor heating in the prior art is solved.

Owner:ZHEJIANG MENRED COMFORT SYST

Tea fermentation equipment with temperature control and ventilation functions

InactiveCN108323593AImprove qualityEasy to control the degree of fermentationPre-extraction tea treatmentTemperature controlHeat conducting

The invention relates to tea fermentation equipment with temperature control and ventilation functions. The tea fermentation equipment comprises a main body and four support blocks. A PLC (programmable logic controller), a fermentation chamber, a fixing mechanism, a temperature control mechanism and a ventilation mechanism are arranged in the main body; the temperature control mechanism comprisesa heat conducting tube, an air exhauster, a heat radiating unit and a heat absorption unit; the heat radiating unit comprises a heat radiating tube and a heat radiating box; the heat absorption unit comprises a heat absorption tube, a heating tube and a heating box; and the ventilation mechanism comprises a drive unit, a piston, a compression tube, a first valve and an exhaust tube. The tea fermentation equipment with the temperature control and ventilation functions can regulate the tea fermentation temperature according to tea fermentation time by the aid of the temperature control mechanism, so that the temperature at each stage during tea fermentation is the most suitable temperature for tea fermentation, and the tea quality can be improved. Moreover, the tea fermentation equipment canregulate the ventilation volume according to the tea fermentation time by means of the ventilation mechanism, thus, the tea fermentation degree is convenient to control, and the tea quality can be improved.

Owner:南安市瑞欣生物科技有限公司

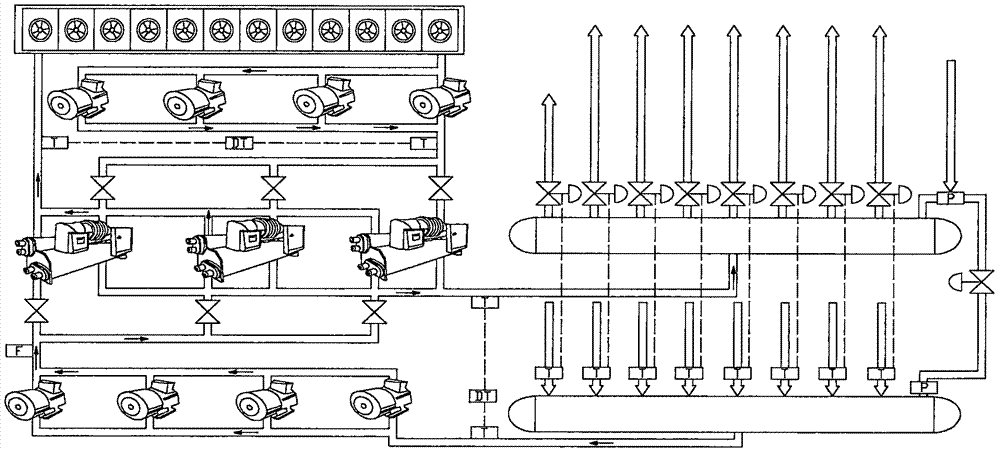

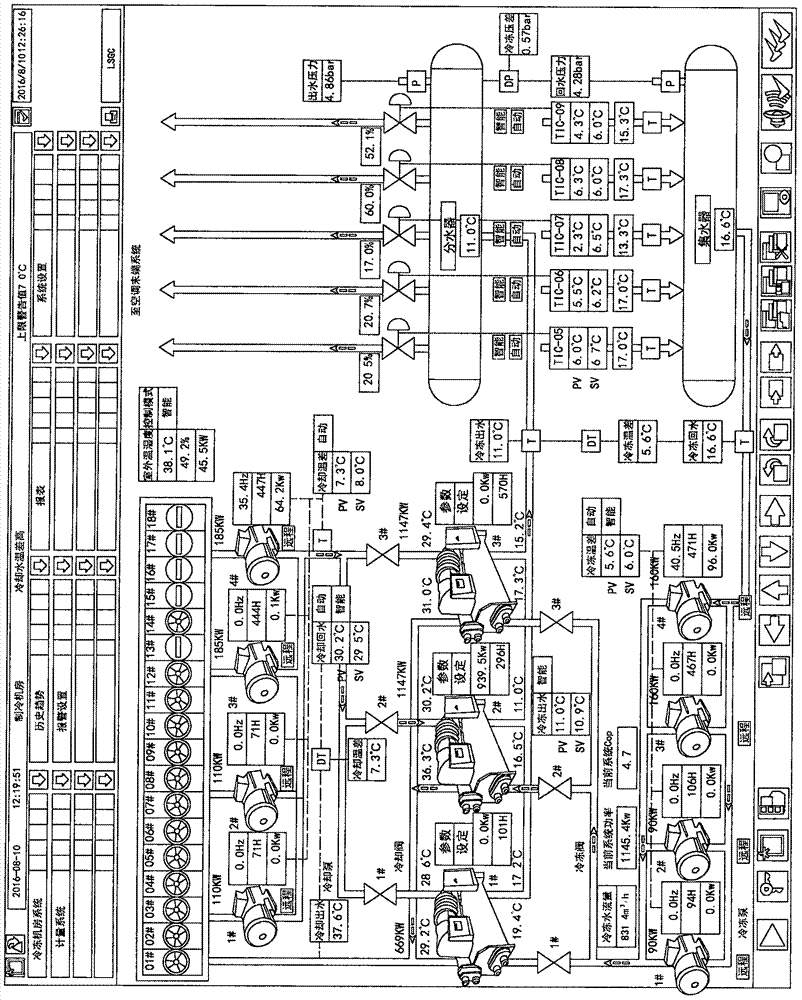

Method for intelligent control over refrigeration host in central air-conditioning monitoring system

InactiveCN106801975AHigh temperature regulation accuracyImprove dynamic performanceMechanical apparatusSpace heating and ventilation safety systemsMonitoring systemEngineering

The invention relates to a method for intelligent control over a refrigeration host in a central air-conditioning monitoring system. The method is designed for solving the technical problem that design of a method for intelligent control over a refrigeration host in an existing central air-conditioning monitoring system is poor. The method is characterized in that the central air-conditioning monitoring system of the control method is provided with a frozen water outlet button, the optimal host water outlet temperature of a cold water unit is manually input on a host frozen water adjusting panel, the host water outlet temperature value is set and switched into an intelligent mode, in other words, the host water outlet temperature value is put into the COP maximum value search algorithm, and the optimal host water outlet temperature set value is automatically sought; according to the COP maximum value search algorithm, the running effect of the whole central air-conditioning operation time frame is displayed through one COP curve and another system power energy consumption curve, in other words, the COP slowly searches for the optimal value in the system running period, and the state is constantly kept to the shutdown time. Meanwhile, the central air-conditioning monitoring system is provided with large hosts and small hosts, at most two large hosts are started, and the power and the number of the large hosts and the small hosts are matched with the cold load in real time.

Owner:杭州裕达自动化科技有限公司

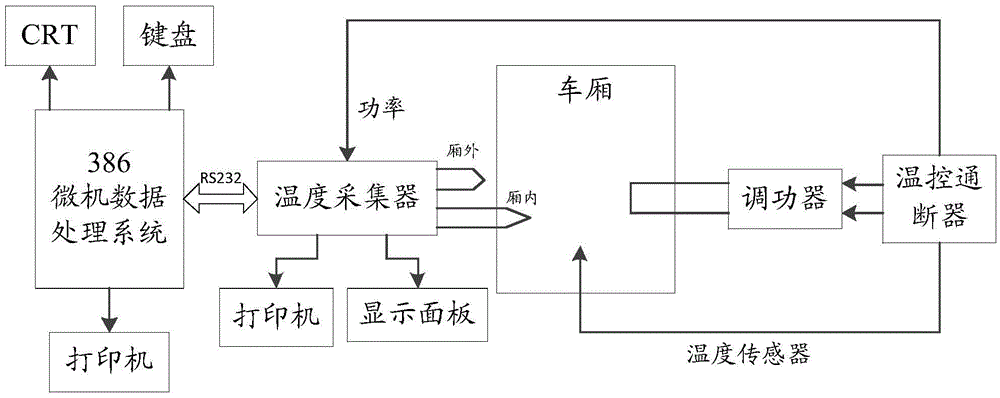

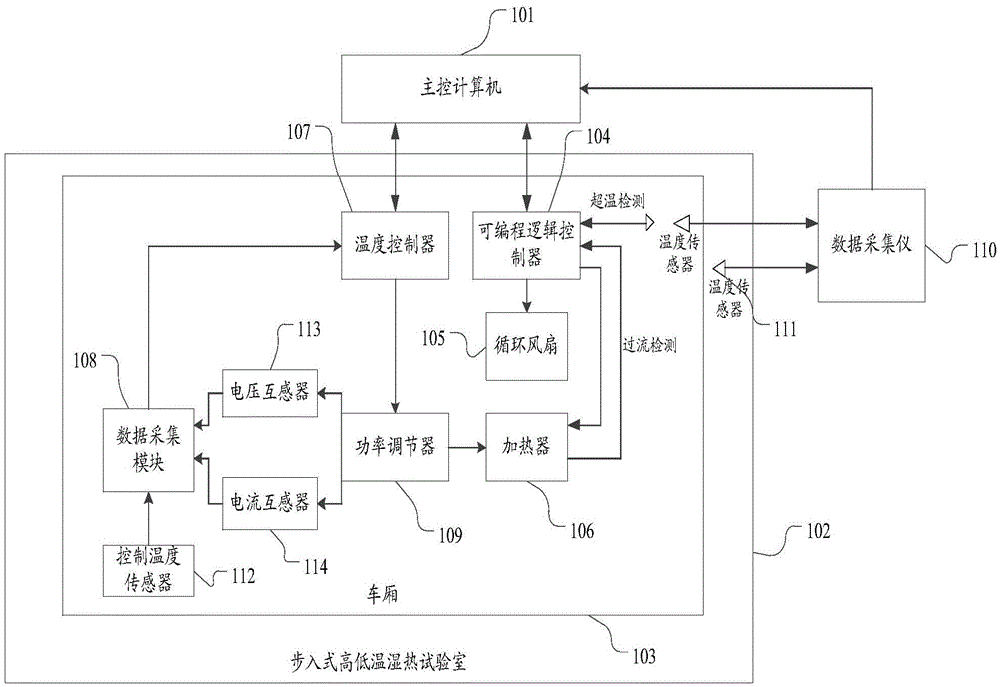

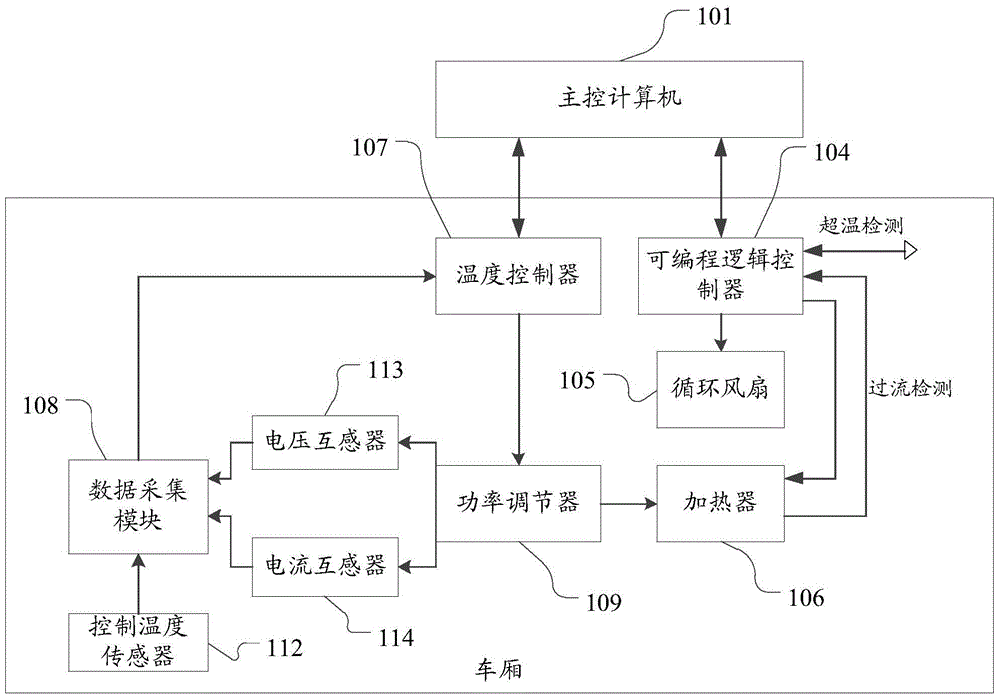

Compartment heat transfer coefficient test system and compartment temperature control system

ActiveCN104198527BUniform temperature distributionMeet the heat transfer coefficient testMaterial heat developmentAuxillary controllers with auxillary heating devicesTemperature controlAutomatic control

The invention provides a carriage heat transfer coefficient testing system and a control system for the temperature in the carriage. The carriage heat transfer coefficient testing system comprises a main-control computer, a PLC (programmable logic controller), a circulating fan, a heater, a temperature controller, a data collecting module, a power regulator, a data acquisition instrument, a temperature sensor and a controlled temperature sensor. The carriage heat transfer coefficient testing system and the control system for the temperature inside the carriage adopts a walk-in type high-low temperature humidity test chamber, so as to ensure the temperature sampling precision in the exterior of the carriage; through the circulating fan, the temperature uniformity in the interior of the carriage is ensured, so that the temperature sampling precision in the interior of the carriage is improved; the heater is adopted for heating, so as to meet the heating requirements of carriages with various volumes; the temperature controller automatically and precisely regulate the output current and the voltage of the power governor according to received signals, so that the heater is automatically controlled to heat to the set temperature; the precision of temperature regulation is high and the stability of the temperature regulation is good; the main-control computer per se conducts the calculation of the heat transfer coefficient according to the received data; the precision of the testing results is high.

Owner:广电计量检测(武汉)有限公司 +1

Intelligent electricity-saving control method for cooling towers in central air-conditioner monitoring system

InactiveCN107036231AHigh temperature regulation accuracyGood dynamic performanceMechanical apparatusSpace heating and ventilation safety systemsCooling temperatureProcess engineering

The invention relates to an intelligent electricity-saving control method for cooling towers in a central air-conditioner monitoring system. The intelligent electricity-saving control method is designed to solving the technical problem that in existing central air-conditioner monitoring systems, design of intelligent electricity-saving control methods for cooling towers is in lack of convenience. The intelligent electricity-saving control method is mainly characterized in that a temperature sensor on a pipe arranged between a cooling pump and a cooling water inlet valve of a refrigeration main machine is a cooling water returning temperature sensor; the cooling water returning temperature sensor is connected with temperature sensors at three positions, namely the temperature sensor arranged at the cooling water outlet position of water outlet of the refrigeration main machine, the temperature sensor arranged at the position where a cooling temperature difference of water inlet of the refrigeration main machine is generated and the temperature sensor arranged at the position where a cooling temperature difference of water outlet of the cooling pump is generated; two modes, namely the automatic mode and the intelligent modes, are arranged for the cooling water returning temperature sensor, and thus in the specific operation process of a central air-conditioner, by means of an intelligent algorithm in which the cooling towers are cut away, manual control over the number of the cooling towers is achieved; and by means of a touch screen end of cooling tower equipment, real-time monitoring is conducted, a real-time online sorting algorithm is adopted for operation time of the cooling towers, a time balanced control strategy is guaranteed, and for each time, the cooling tower which runs for the longest time is started and the tooling tower which runs for the shortest time is switched off.

Owner:杭州裕达自动化科技有限公司

Far infrared intelligent electric heating table and control circuit thereof

InactiveCN103225842AReasonable designSimple structureLighting and heating apparatusElectric heatingEngineeringFar infrared

The invention discloses a far infrared intelligent electric heating table and a control circuit thereof. The electric heating table comprises a table body, wherein an electric heating plate is embedded into the table top of the table body; an electric heating footrest is arranged at the lower part of the table body; the electric heating plate and the electric heating footrest are controlled to work by the control circuit; and the control circuit comprises an electric heating plate control circuit and an electric heating footrest control circuit in parallel connection. The electric heating table disclosed by the invention has the advantages of simple structure, low manufacturing cost, long service life and high temperature regulation precision, is convenient to use, is energy-saving and environment-friendly, and does not take much space; and moreover, far infrared rays have a healthcare function to people, and the electric heating table is safe to use since no open fire is used.

Owner:广州美尼美家具有限公司

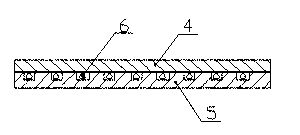

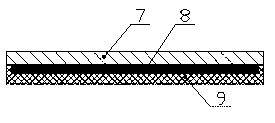

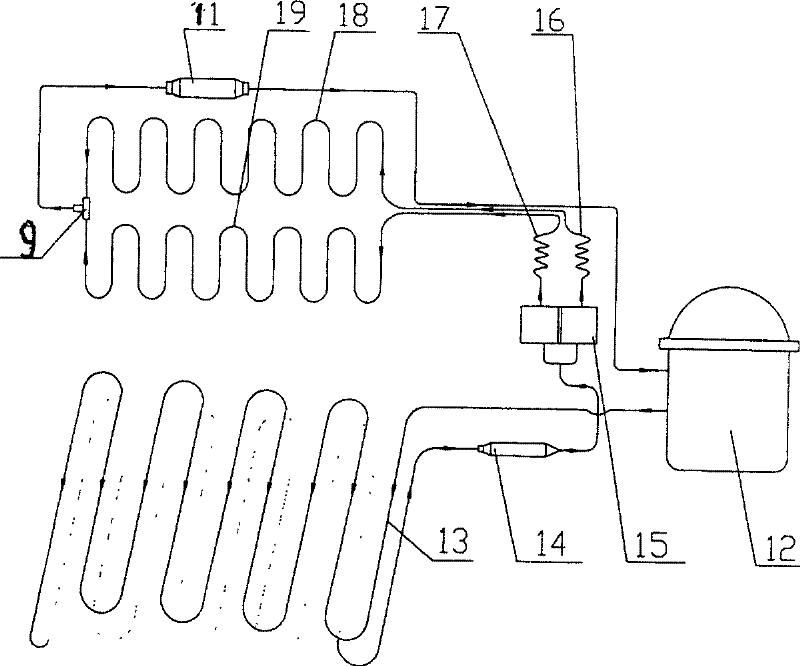

Double temperature double control wine cabinet evaporator

ActiveCN101097103AGood air circulationIncrease usageEvaporators/condensersRefrigerantAgricultural engineering

The invention discloses an evaporator of chill box, which is characterized by the following: setting the evaporator as inflating type evaporator or plate type evaporator; arranging at least one ventilation slot at the lateral of the inflating evaporator or plate evaporator; setting the evaporator as full liquid type evaporator; setting the conduit line of the evaporator as flood type structure; flowing the cooling agent from lower to upper; increasing cooling efficiency. This invention possesses good air flowing effect, which can increase cooling effect.

Owner:HAIER GRP CORP +1

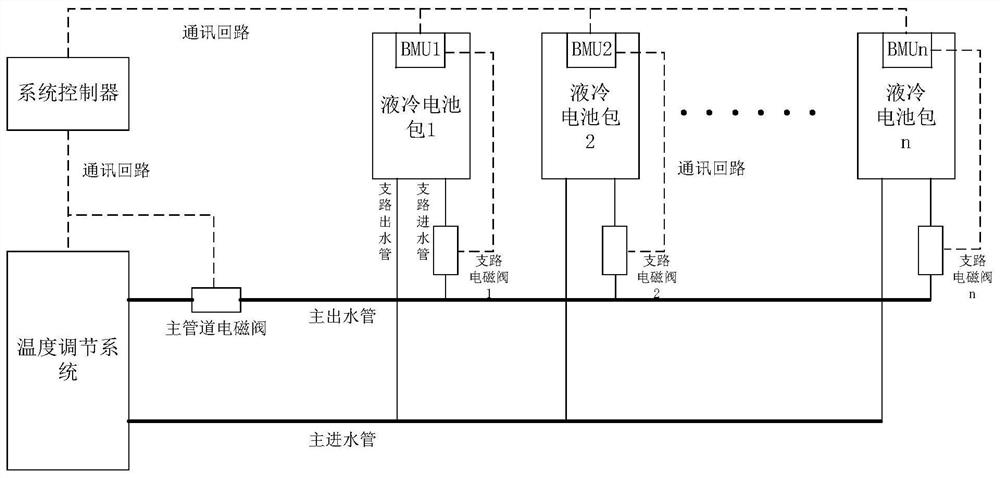

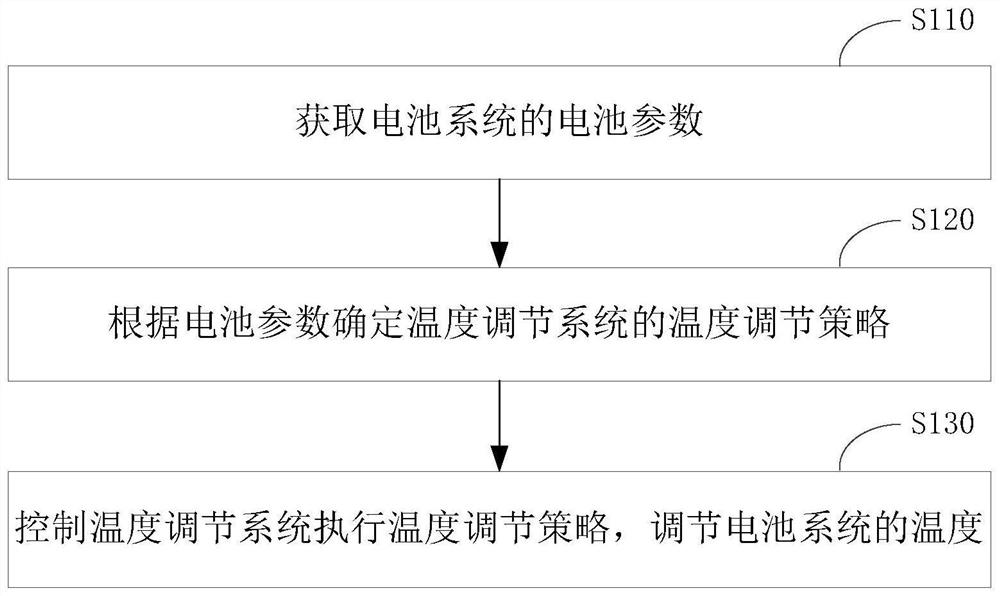

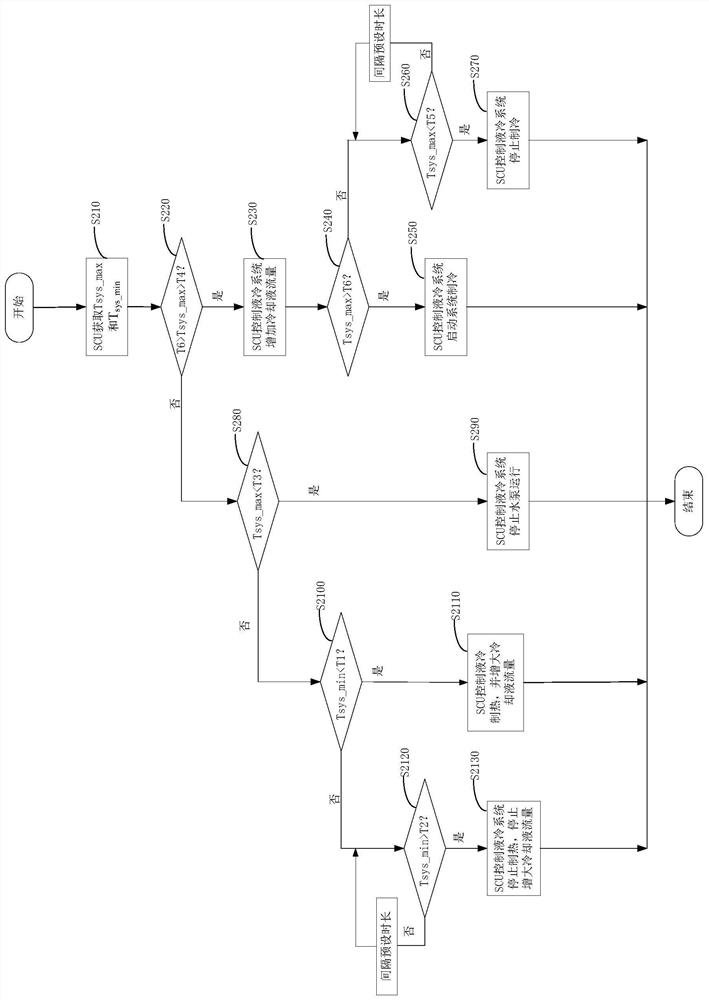

Thermal management method of energy storage system, controller and energy storage system

ActiveCN113097597AHigh temperature regulation accuracyCell temperature controlHeat managementControl engineering

The invention provides a thermal management method of an energy storage system, a controller and the energy storage system. The method comprises the steps: obtaining battery parameters of a battery system, further determining a temperature adjustment strategy of a temperature adjustment system according to the obtained battery parameters, and triggering the temperature adjustment system to execute the determined temperature adjustment strategy to adjust the temperature of the battery system. The scheme is applied to a system-level controller, the system-level controller and the temperature adjustment system achieve linkage control and coordinated control, the system-level controller determines a temperature adjusting strategy of the temperature adjustment system according to battery parameters of the battery system, then the temperature adjustment system is controlled to execute the temperature adjustment strategy, and finally, the temperature adjustment system adjusts the temperature of the battery system according to the battery parameters, so that the temperature adjusting precision of the battery system is improved.

Owner:SUNGROW POWER SUPPLY CO LTD

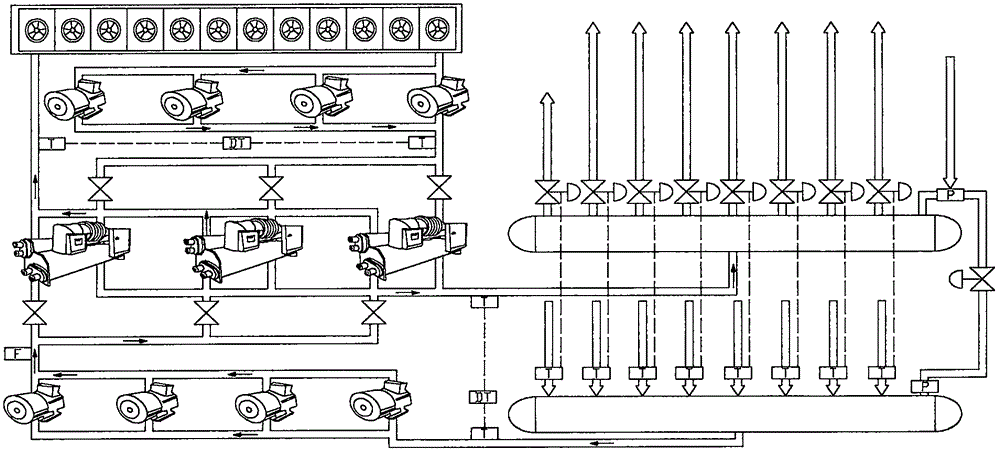

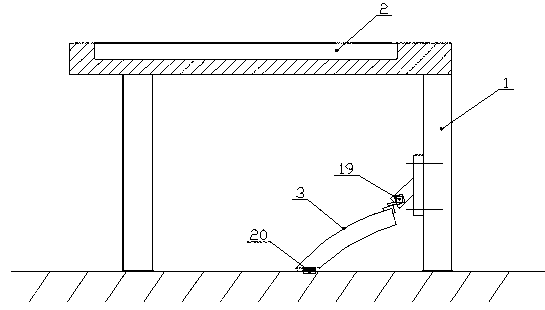

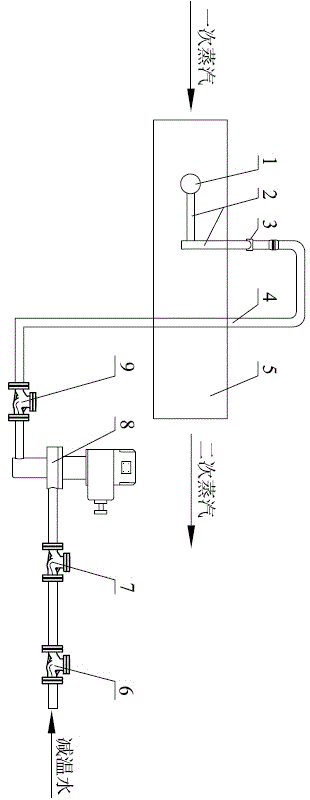

Tail end cold and heat quantity balancing and redistributing power-saving control method in central air-conditioning monitoring system

PendingCN106839274AHigh temperature regulation accuracyImprove dynamic performanceMechanical apparatusSpace heating and ventilation safety systemsPower savingWater recovery

The invention relates to a tail end cold and heat quantity balancing and redistributing power-saving control method in a central air-conditioning monitoring system and is designed for solving the technical problem that cold and heat quantity balancing and redistributing power-saving management of a tail end branch of a water distributor in the central air-conditioning monitoring system is inconvenient. The key point of the system is as follows: a heat supply portion of the control method comprises a steam boiler, a hot water pump, a plate type heat exchanger and electromagnetic valves; the hot water pump is connected to the plate type heat exchanger and a water collector through a pipeline, winter air conditioning hot water supply of the air-conditioning refrigerating system is connected to the water distributor through a pipeline, the steam boiler is connected to the plate type heat exchange through a pipeline, the electromagnetic valves are separately arranged on branch general pipes of the plate type heat exchanger, the plate type heat exchanger is connected to the water distributor, the branches of the pipeline are separately provided with temperature sensors, and the water outlet of the plate type heat exchanger is connected to a condensate water recovery pond through a pipeline, and moreover, energy conservation optimization is performed on the tail end of the cold quantity by combining a multi-regional cold quantity balanced distribution energy control technology and cold quantity fuzzy pre-judgment energy-saving control technology.

Owner:杭州裕达自动化科技有限公司

Comprehensive low-noise constant-temperature laser receiving system

ActiveCN1936617BHigh temperature regulation accuracyNo human intervention requiredElectromagnetic wave reradiationOptical elementsLow noiseSatellite laser ranging

The invention discloses a laser receiver system of low yawp and constant temperature. The collimating lens (1), the light filter (2), the angle reflector (3), the photoelectric receiver (5) are set inthe cylinder (0) from the right to the left. The CCD (4), the temperature adjustment system (6) and the transmission gear (7) are set on the top of the cylinder; the transmission gear (7) includes thefirst transmission gear (7A) and the second transmission gear (7B); the light filter (2) is connected to the first transmission gear and the reflector (3) is connected to the second transmission gear (7B); the position of the CCD is correspond to the angle reflector (3). The invention has the function of constant temperature, light filter and light tine adjustment. So it can be used for the lidar , the satellite laser ranging, the spacecraft tracking, the stellar tracking observation and the space fragment dynamic tracking.

Owner:INST OF EARTHQUAKE CHINA EARTHQUAKE ADMINISTRATION

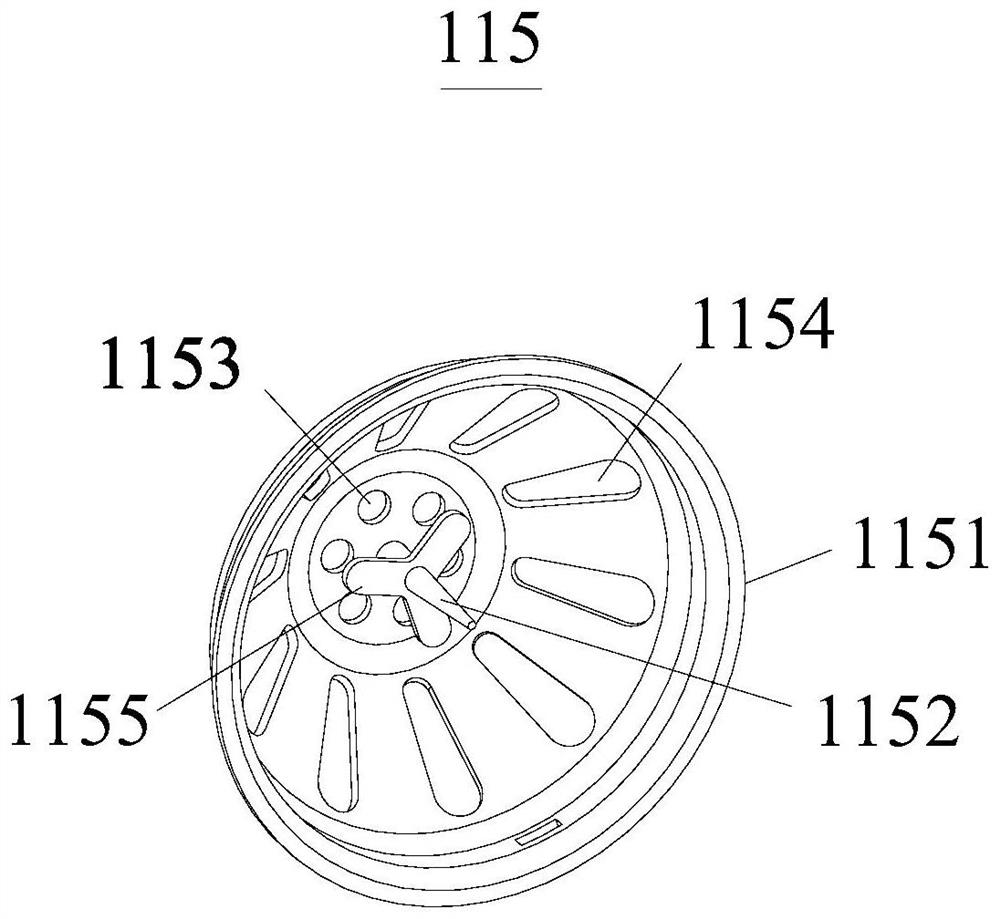

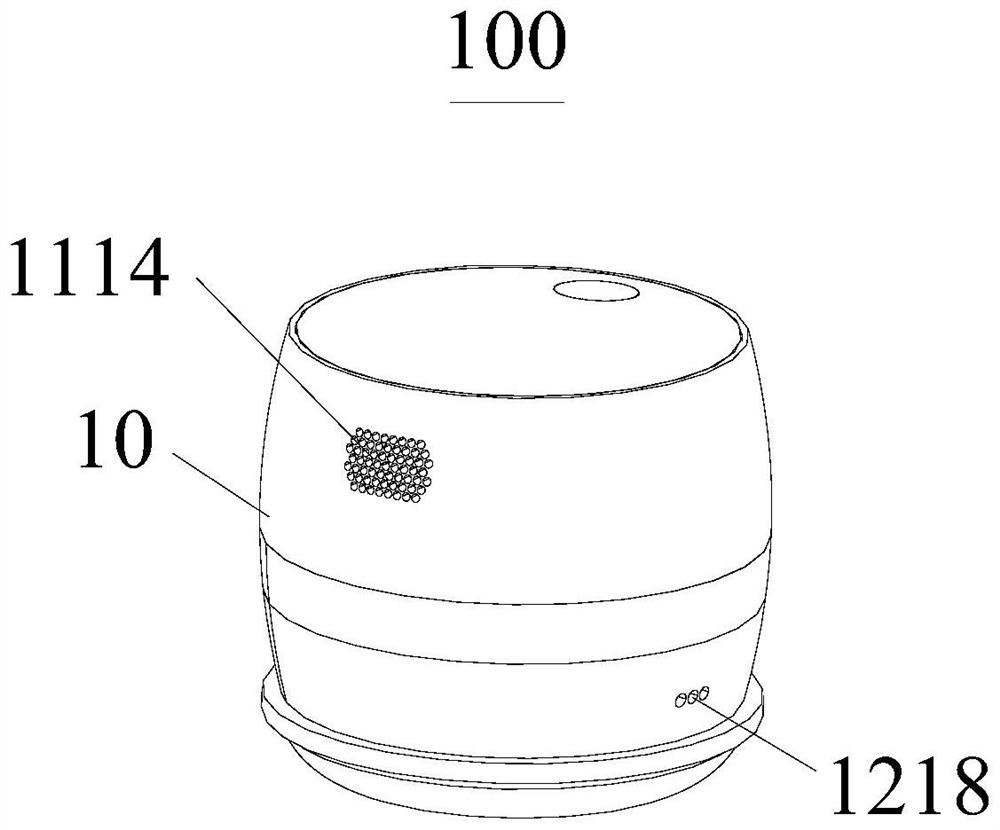

Moxa cone fixing device and moxibustion device thereof

PendingCN114272115ASpeed up the flowBurning section is evenDevices for heating/cooling reflex pointsCurative effectEngineering

The invention discloses a moxa cone fixing device which comprises a bowl-shaped body and a fixing column, the fixing column is vertically arranged at the bottom of the bowl-shaped body and extends to the concave side, and a circle of air passing holes surrounding the fixing column are formed in the bottom of the bowl-shaped body. A circle of air passing groove surrounding the fixing column is formed in the peripheral wall of the bowl-shaped body. The invention further discloses a moxibustion device using the moxa cone fixing device, the moxibustion device comprises a body, an air channel is arranged in the body, and the moxa cone fixing device is arranged in the air channel. The moxibustion device has the advantages of being accurate in temperature adjustment, uniform in temperature output and good in moxibustion curative effect.

Owner:GUANGZHOU NEW DESIGN BIOTECHNOLOGY CO LTD

Automatic thermostatic control instrument for swimming pool

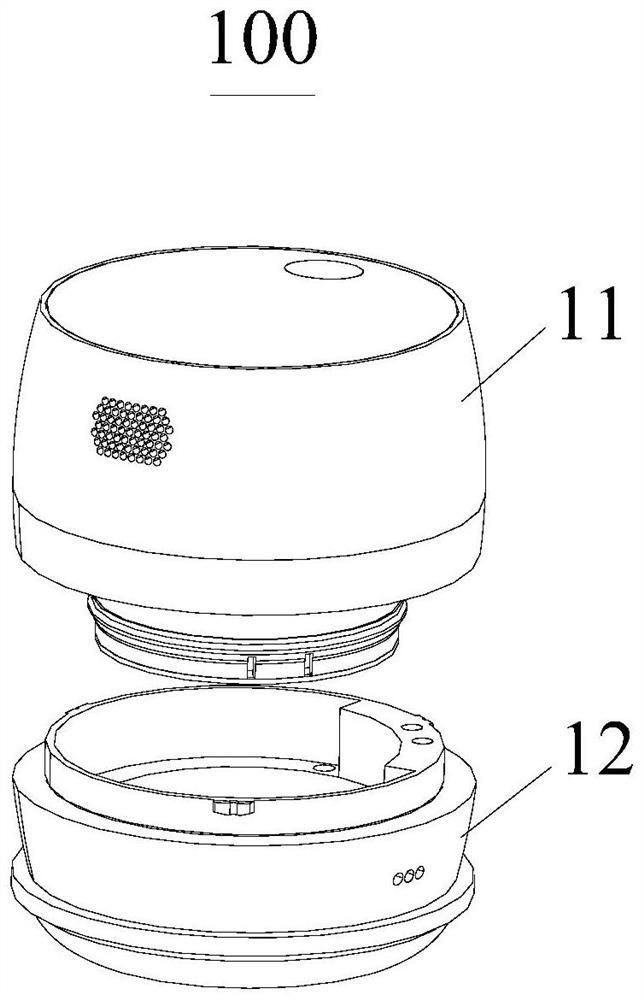

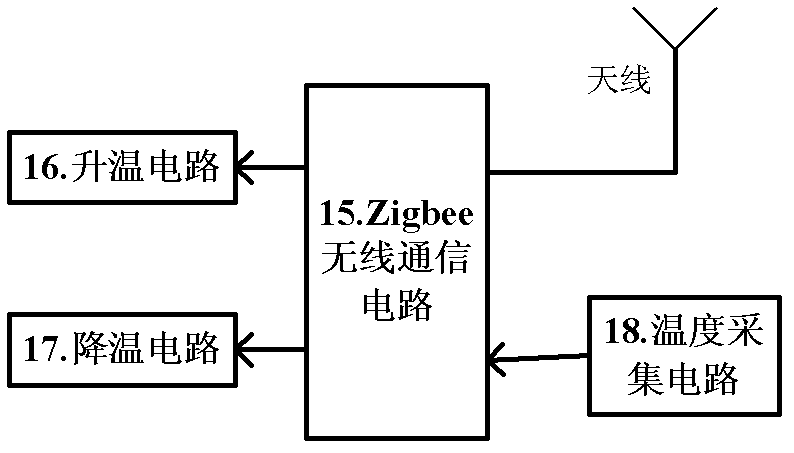

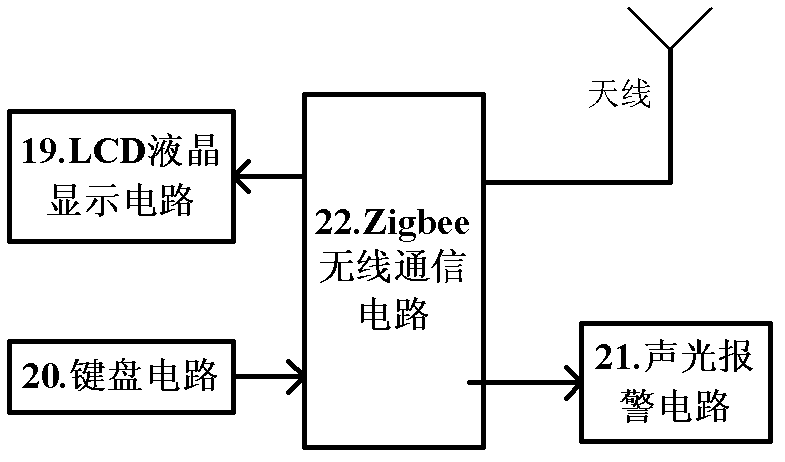

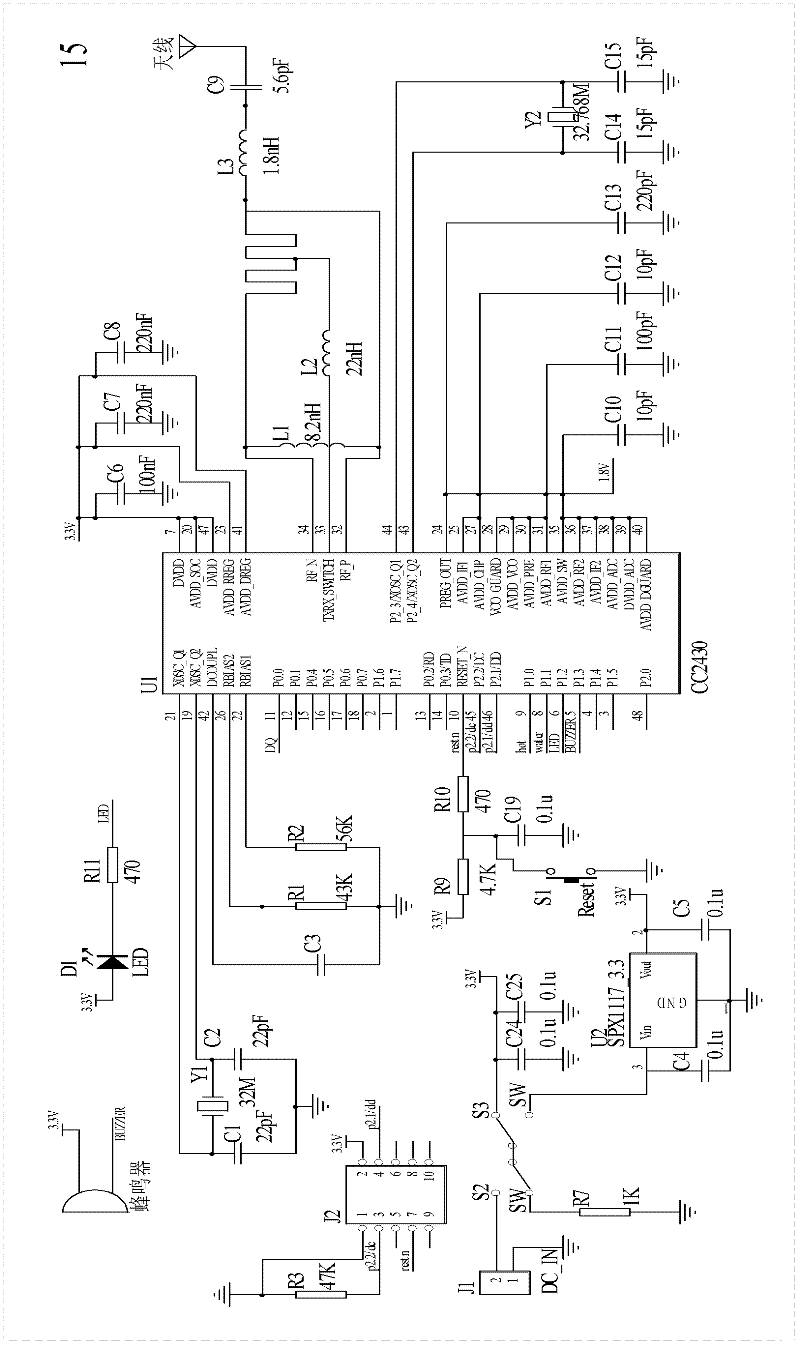

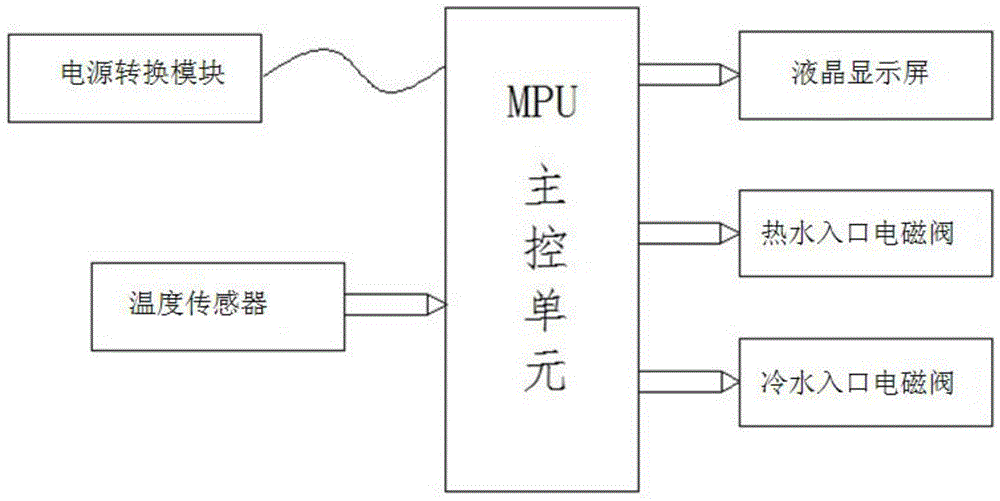

InactiveCN102508505ALow costImprove acquisitionTemperatue controlLiquid-crystal displayControl circuit

The invention provides an automatic thermostatic control instrument for a swimming pool. The automatic thermostatic control instrument is characterized in that an executive circuit of the automatic thermostatic control instrument for the swimming pool is in wireless communication connection with a control circuit of the automatic thermostatic control instrument for the swimming pool; the executive circuit of the automatic thermostatic control instrument for the swimming pool comprises a first ZigBee wireless communication circuit, a heating circuit, a cooling circuit and a temperature collecting circuit; the first ZigBee wireless communication circuit is the core part of the executive circuit of the automatic thermostatic control instrument for the swimming pool and is connected with the heating circuit, the cooling circuit and the temperature collecting circuit; the control circuit of the automatic thermostatic control instrument for the swimming pool comprises a second ZigBee wireless communication circuit, an LCD (Liquid Crystal Display) circuit, a keyboard circuit and an audible and visual alarm circuit; and the second ZigBee wireless communication circuit is the core part of the control circuit of the automatic thermostatic control instrument for the swimming pool and is connected with the LCD circuit, the keyboard circuit and the audible and visual alarm circuit. The automatic thermostatic control instrument provided by the invention can be used for controlling the water temperature of the swimming pool to reach a preset temperature fast and accurately and ensuring that the water temperature remains constant.

Owner:NORTHEAST DIANLI UNIVERSITY

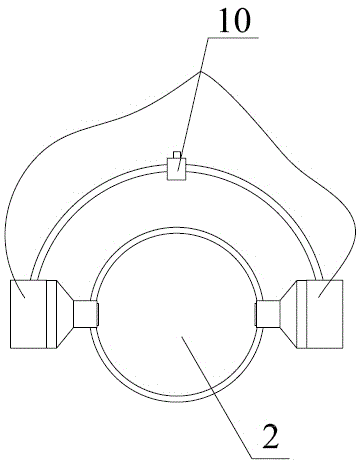

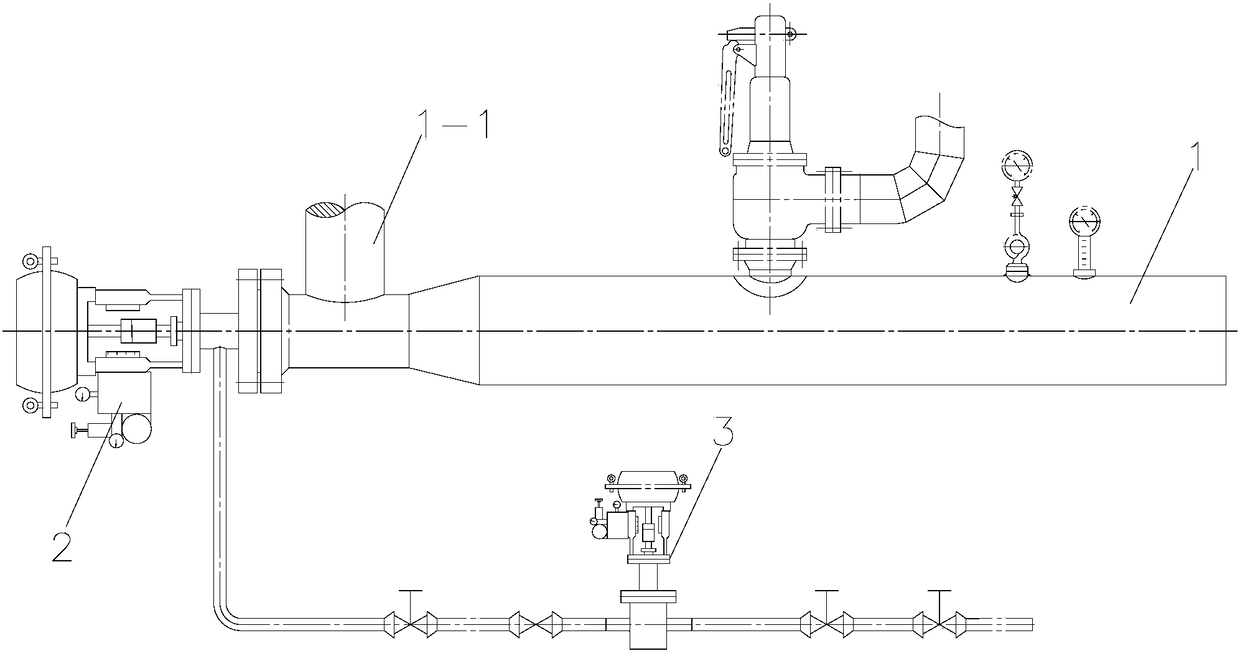

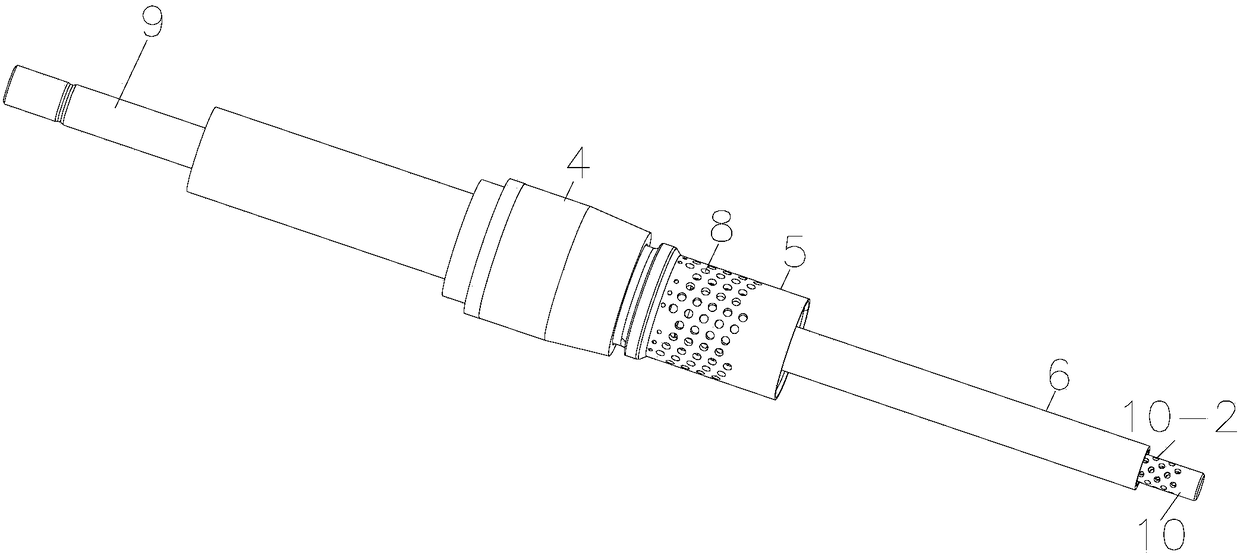

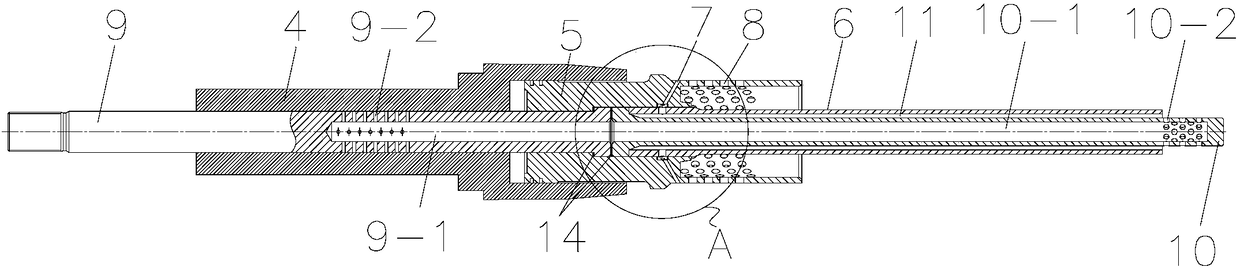

Spherical spraying nozzle desuperheater

The invention discloses a spherical spraying nozzle desuperheater which is wider in jetting range, better in atomization effect of attemperation water, wider in application range, higher in adjustment accuracy and lower in noise. According to the technical scheme, the spherical spraying nozzle desuperheater is characterized in that a spherical spraying nozzle is fixed in a mixed pipeline through a fixing device; the fixing device is adjustable; through holes are uniformly distributed in the spherical spraying nozzle; one end of a short pipeline is connected with a long pipeline through a connector, and the other end of the short pipeline is connected with the spherical spraying nozzle; and the height of the spherical spraying nozzle is adjustable.

Owner:付开领

Water temperature adjusting device of solar water heater

InactiveCN104456988AImprove flowHigh temperature regulation accuracySolar heat devicesSolar thermal energy generationBall bearingLiquid-crystal display

Disclosed is a water temperature adjusting device of a solar water heater. A hot water inlet solenoid valve and a cold water inlet solenoid valve are fixed to the upper end of a shell, a water outlet is formed in the lower end of the shell, a liquid crystal display screen and an adjusting knob input module are arranged at the front end of the shell, the input end of a power conversion module is connected with a power transmission line, the output end of the power conversion module is connected with an MPU master control unit, a temperature sensor and the liquid crystal display screen, and the MPU master control unit is connected with the liquid crystal display screen, the temperature sensor, the hot water inlet solenoid valve and the cold water inlet solenoid valve. A water insulation plate is fixedly arranged in the middle in the shell, a thrust ball bearing and an angular contact ball bearing are fixed to the bottom and top in the shell respectively, a water mixing shaft penetrates through a hole in the water insulation plate, the upper end of the water mixing shaft is fixed to the angular contact ball bearing, the lower end of the water mixing shaft is fixed to the thrust ball bearing, the temperature sensor is fixedly arranged beside the water outlet, and a blade is arranged on the water mixing shaft. The water temperature adjusting device is reasonable in structural layout, good in temperature adjusting effect, high in precision and suitable for application and popularization.

Owner:GUANGXI UNIV

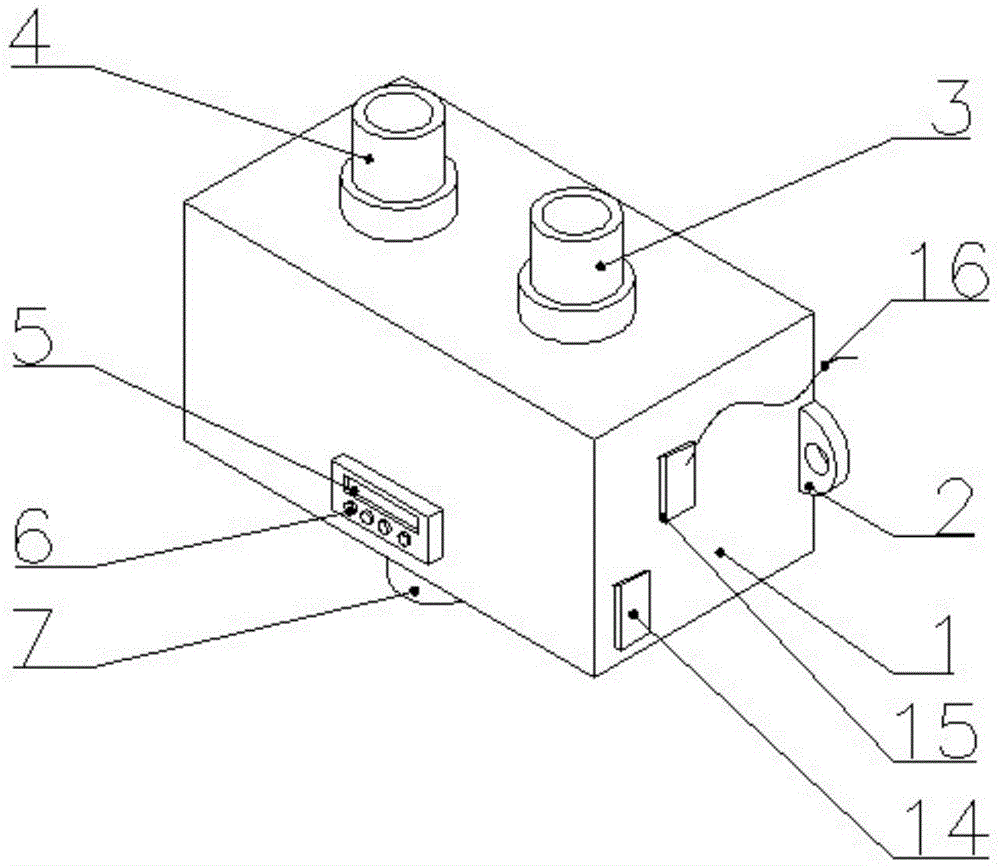

Integrated temperature and pressure reduction device

ActiveCN105698006BIncrease contact areaFacilitate contact areaSuperheating controlValve members for absorbing fluid energyWater channelEngineering

The invention relates to the technical field of valve manufacturing, in particular to an integrated temperature and pressure reduction device, which includes a secondary steam pipeline and a temperature and pressure reduction mechanism arranged in the secondary steam pipeline. The temperature and pressure reduction mechanism includes an upper valve cover And the spool, the spool is provided with a number of pressure-reducing holes, one end of the spool is inserted with a valve stem, and the end of the valve stem close to the spool is provided with a water delivery channel, and the outer peripheral surface of the valve stem is provided with a number of water delivery channels. The other end of the valve core is inserted with a desuperheating water pipe, the end of the desuperheating water pipe close to the valve stem is provided with a water outlet, the outlet channel is connected with the water delivery channel, and the outer peripheral surface of the end of the desuperheating water pipe far away from the valve core is provided with a There are several water outlet holes, and the water outlet holes are connected with the water outlet. The invention increases the contact area between the primary steam and the desuperheating water, ensures a good temperature and decompression effect, high adjustment accuracy, and compact structure.

Owner:WUZHONG INSTR

Central control switch of intelligent air conditioner

InactiveCN106427464AHigh temperature regulation accuracyAir-treating devicesVehicle heating/cooling devicesMembrane switchEngineering

The invention discloses a central control switch of an intelligent air conditioner. The central control switch comprises a main panel, a bar-shaped control handle, film switches, an LED indicating lamp group, a vibrating motor and a control circuit board, wherein the bar-shaped control handle is arranged in the center of the main panel; the film switches are arranged on upper ends and lower ends of the left side and the right side of the bar-shaped control handle, and are connected with the control circuit board; the LED indicating lamp group is arranged on the upper surface of the bar-shaped control handle and is connected with the control circuit board; the vibrating motor is arranged on the surface of the control circuit board; and the control circuit board is arranged in the bar-shaped control handle and is connected with a vehicle through a control interface. Through the adoption of the central control switch of the intelligent air conditioner provided by the invention, the temperature of the air conditioner is adjusted in a manner of using two fingers to extrude the film switches, and the temperature adjusting range is fed back by the vibrating motor, so that the temperature adjusting accuracy of the central control switch of the air conditioner is greatly improved.

Owner:SUZHOU UNIV OF SCI & TECH

Double temperature double control wine cabinet and method for enhancing accuracy of temperature control

ActiveCN101097108BBeautiful shapeSmall footprintLighting and heating apparatusDomestic refrigeratorsComputer control systemTemperature control

The invention discloses a double temperature and double controlling sideboard of high temperature controlled accuracy, which is characterized by the following: comprising box body, cooling system and computer controlled system; cascading compressor, condenser, magnetic valve, capillary tube and evaporator as cooling system; combining to one way through pipe tee; turning to compressor; cascading to a closed loop circuit; separating the inner of the box body to upper and lower cold room; setting the evaporator of the cooling system as two; arranging in the upper and lower cold room; connecting the two evaporator to the condenser through own magnetic valve. This invention possesses nice shape and small accommodation area.

Owner:HAIER GRP CORP +1

Infrared heating graphite purifying furnace

InactiveCN103663420AEffective temperature controlQuality improvementCarbon compoundsControl layerGraphite

The invention discloses an infrared heating graphite purifying furnace comprising a shell and a top cover, wherein the outer wall of the shell is provided with a temperature regulator; the inner wall of the shell is provided with an infrared heating temperature control layer controlled by the temperature regulator; and the shell is movably connected with the top cover. The infrared heating graphite purifying furnace has the beneficial effects of novel structure, simplicity in operation, convenience in use, capability of effectively controlling temperature during graphite purification and high in temperature regulation precision so that the graphite purification quality is improved, and the graphite purification effect is enhanced.

Owner:TIANJIN LONGHUI CARBON GRAPHITE PROD

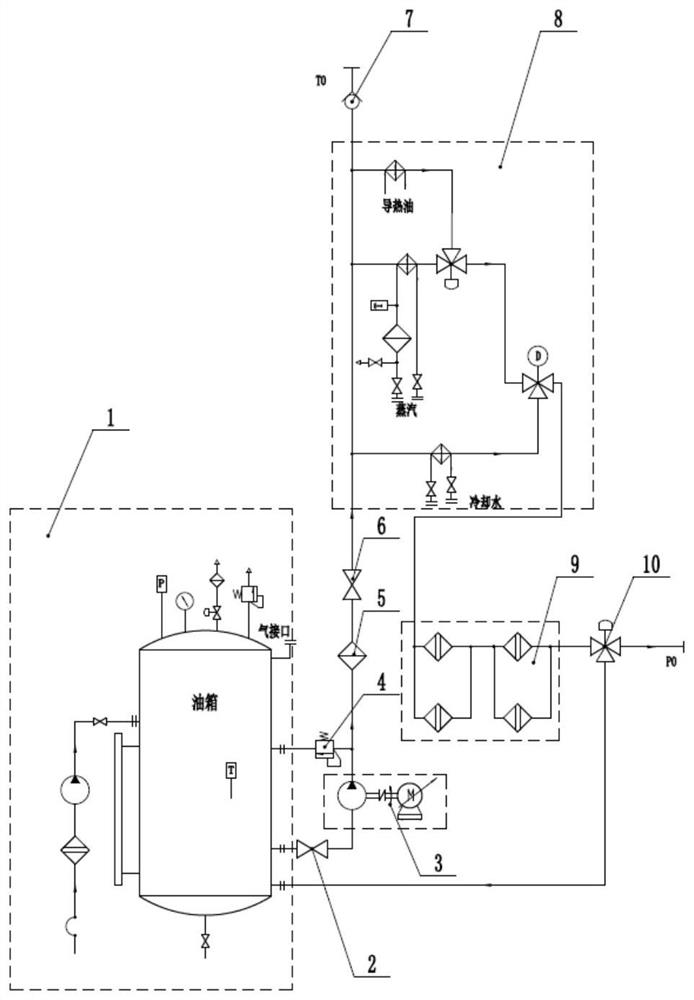

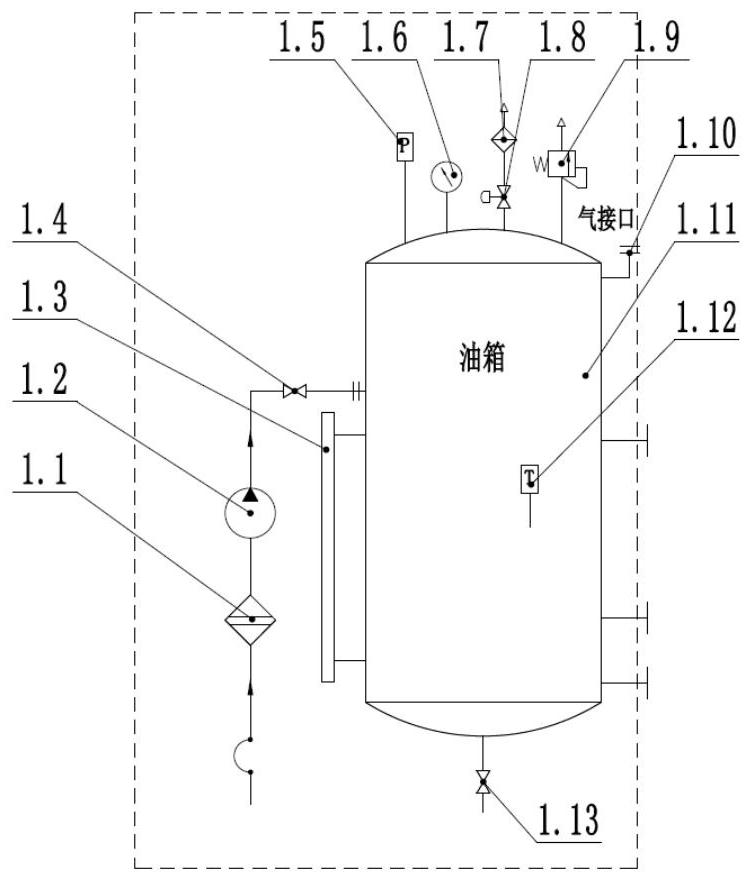

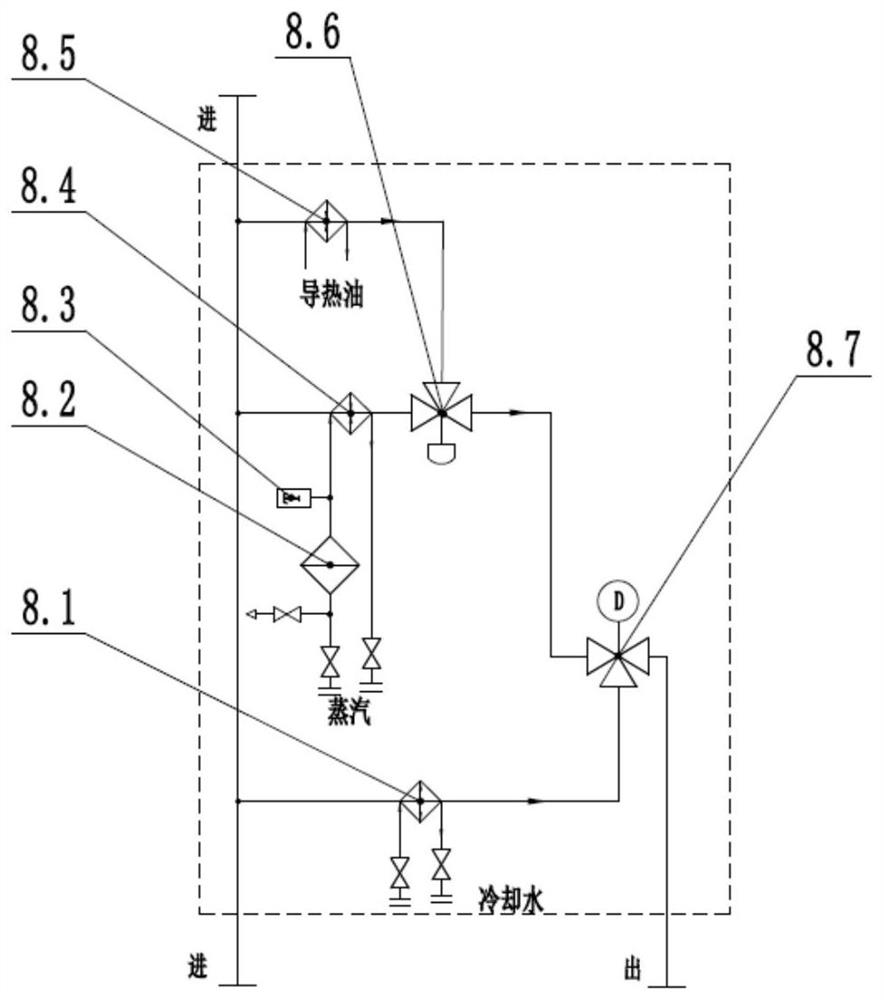

High-temperature fuel servo flow metering characteristic test system

PendingCN114278634AContinuously adjustable temperatureFast lift rateFluid-pressure actuator testingServomotor componentsGas compressorControl engineering

The invention discloses a high-temperature fuel oil servo flow metering characteristic test system which comprises a fuel oil power source system used for providing supercharged fuel oil with adjustable temperature for a fuel oil test system; the fuel oil test system is provided with a fuel oil guide vane control device, a fuel oil distributor, a main fuel oil pump, a simulation fan guide vane actuating cylinder, a simulation gas compressor guide vane actuating cylinder and a simulation nozzle; and the load simulation system is used for providing loads for the simulation fan guide vane actuating cylinder and the simulation compressor guide vane actuating cylinder. The system has the functions of continuously adjustable inlet temperature of a main fuel pump, simulation of a fan guide vane actuator cylinder, simulation of a gas compressor guide vane actuator cylinder, simulation of a nozzle, fuel flow servo metering of main oil ports of all tested pieces, real-time monitoring of pressure / pressure difference and temperature and the like.

Owner:NANJING CHENGUANG GRP

Hoisting air conditioner special for passenger compartment

InactiveCN106482253AReasonable structureCompact structureLighting and heating apparatusSpace heating and ventilation detailsCooling effectEngineering

The invention discloses a hoisting air conditioner special for a passenger compartment. The hoisting air conditioner special for the passenger compartment is characterize in that the hoisting air conditioner comprises a hoisting component, a filter, an electric heating element, a compressor, a first evaporation chamber, a first air duct, a box body, an air blower, a second air duct, flow draught fans and a second evaporation chamber; the hoisting component is arranged at the upper end of the box body, and the one or two or three flow draught fans are connected to the lower end of the box body; the first evaporation chamber and the second evaporation chamber are arranged in the box body; the filter and the electric heating element are sequentially arranged at the left end of the first evaporation chamber; the compressor is arranged on the side wall of the first evaporation chamber; the first evaporation chamber communicates with the second evaporation chamber through the first air duct and the second air duct; and the air blower is arranged at the connection position of the first air duct and the second air duct. The hoisting air conditioner special for the passenger compartment has the beneficial effects that the structure is reasonable and compact; design is ingenious; the occupied space is small; safety and reliability are achieved; stability is high; the cooling effect is good; temperature adjustment precision is high; and the hoisting air conditioner meets energy conservation and environment protection policies initiated by the state. Great economic significance and social significance are achieved.

Owner:史静

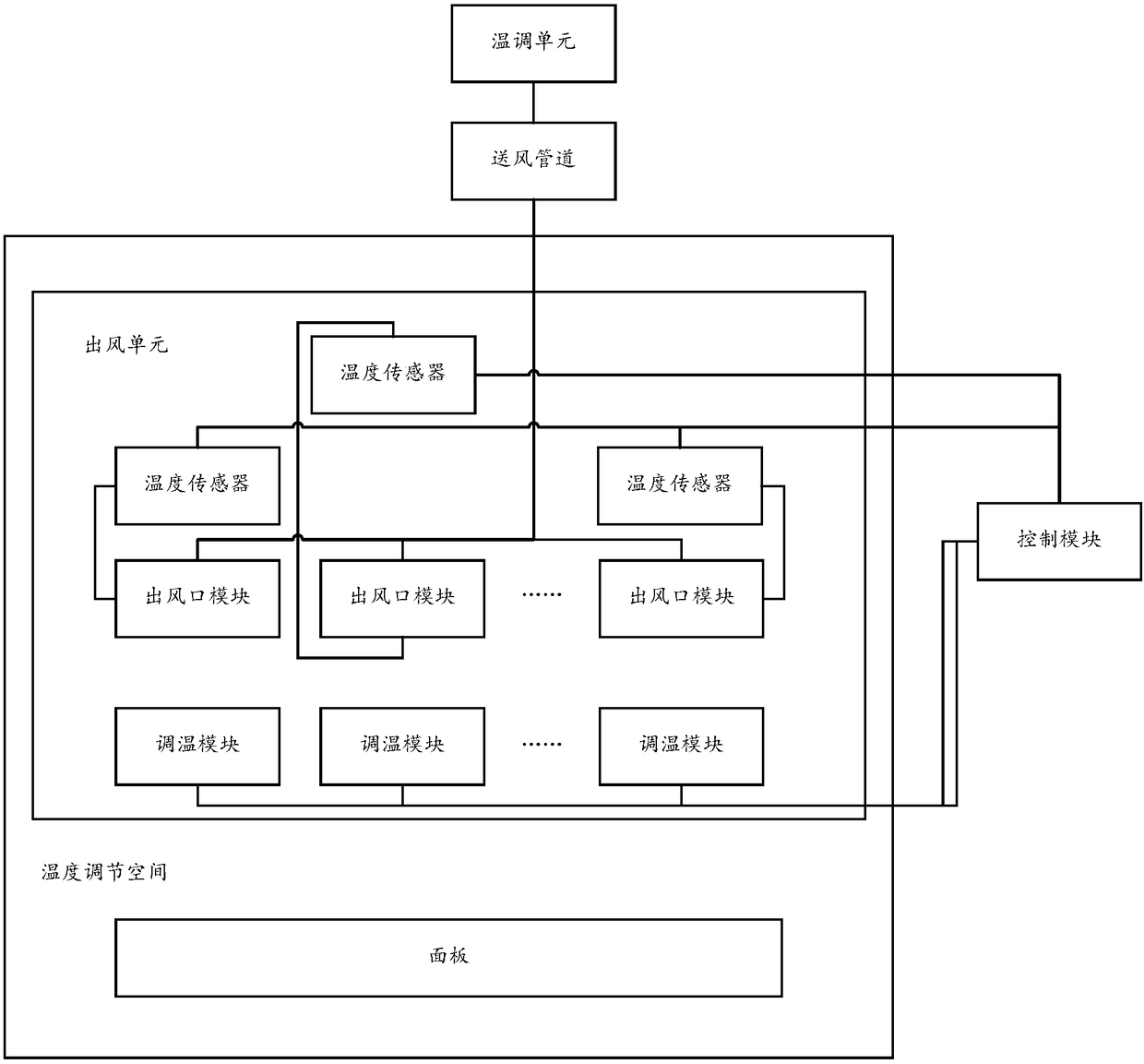

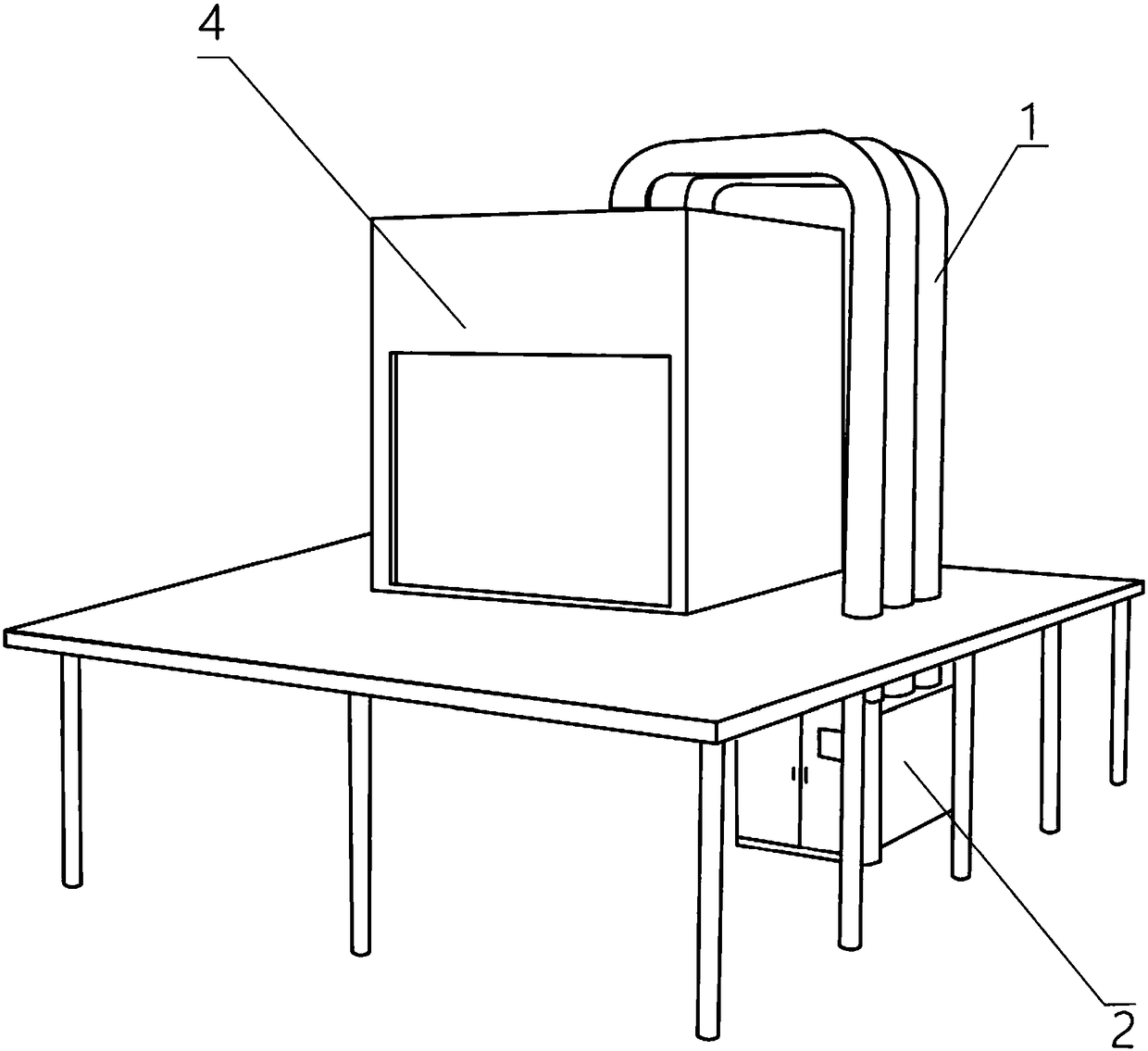

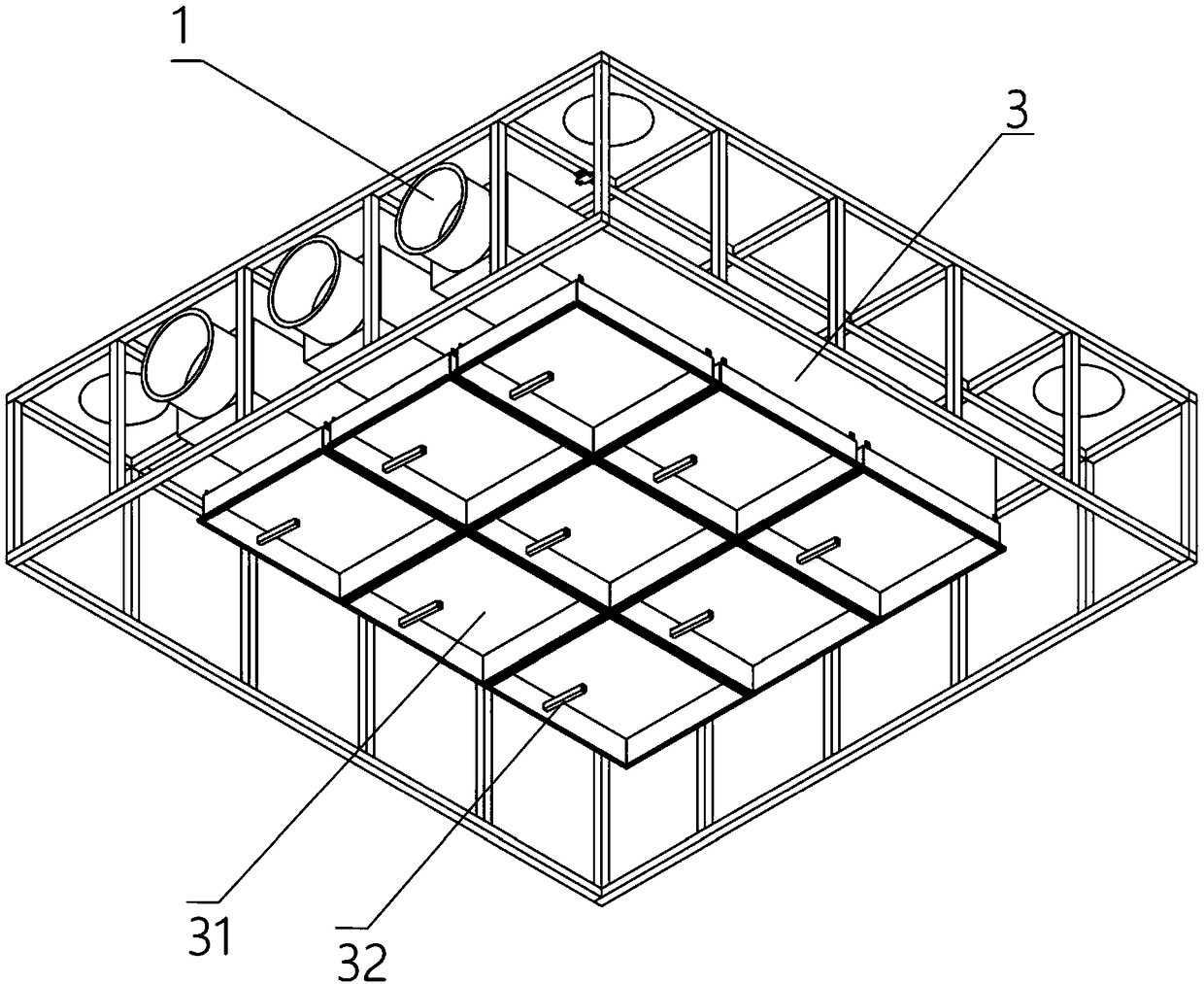

Precise temperature adjustment system and its control method

InactiveCN106774520BHigh temperature control accuracyAvoid chippingTemperatue controlTemperature controlTemperature conditioning

The invention relates to the field of electric equipment, and discloses a precise temperature regulation system and a control method thereof. The precise temperature regulation system is used for performing temperature regulation on a panel arranged in the temperature regulation space, and comprises a control module, a temperature regulation unit, an air outlet unit and an air supply pipeline, wherein the air outlet unit is arranged in the temperature regulating space; the air supply pipeline is connected between the temperature regulation unit and the air outlet unit; the air is conveyed out to the air outlet unit through the air supply pipeline after being subjected to temperature regulation by the temperature regulation unit; the air outlet unit comprises N air outlet opening modules, a plurality of temperature sensors and a plurality of temperature regulation modules; the air outlet opening modules are in opposite arrangement to the panel in an array shape, wherein the N is a natural number being greater than or equal to 2; the plurality of temperature sensors are used for detecting the air outlet temperature in the position of the air outlet opening module; the plurality of temperature regulation modules are used for regulating the temperature of air blown out from the air outlet module; the control module is in communication connection with the temperature sensors and the temperature regulation modules, and is used for controlling the output of the temperature regulation modules according to the temperature detected by the temperature sensor. The precise temperature regulation system can improve the temperature control precision of the panel surface.

Owner:FUJI ELECTRIC CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com