Compartment heat transfer coefficient test system and compartment temperature control system

A technology of heat transfer coefficient and test system, which is applied in the direction of temperature control using electric method, auxiliary controller with auxiliary heating device, material thermal development, etc. The temperature fluctuation is relatively large and other problems, to achieve the effect of balancing the temperature, improving the test efficiency, and high temperature adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

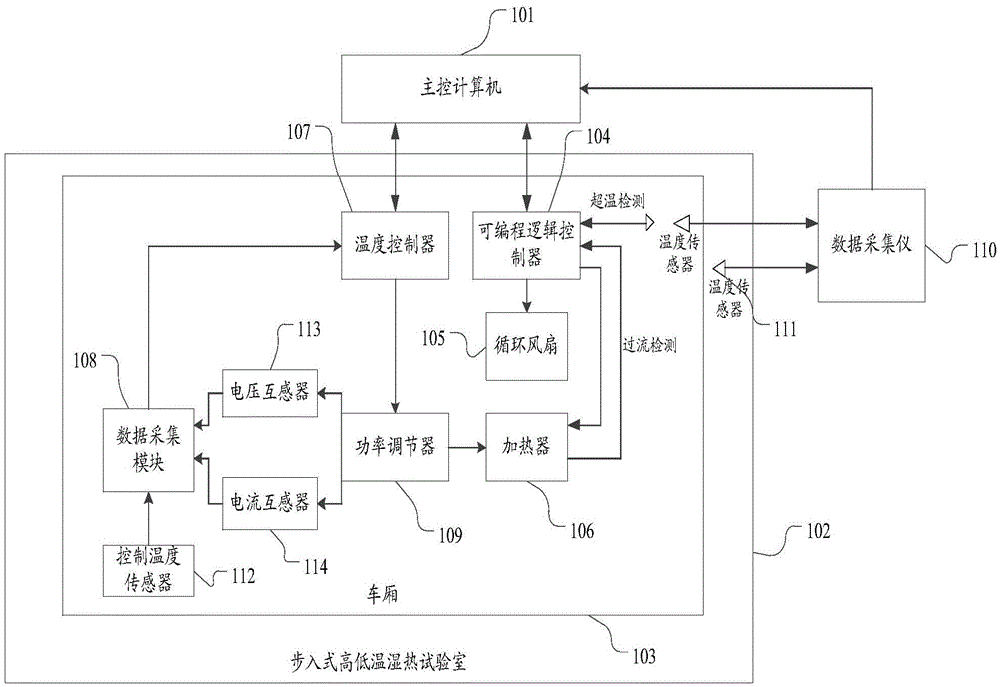

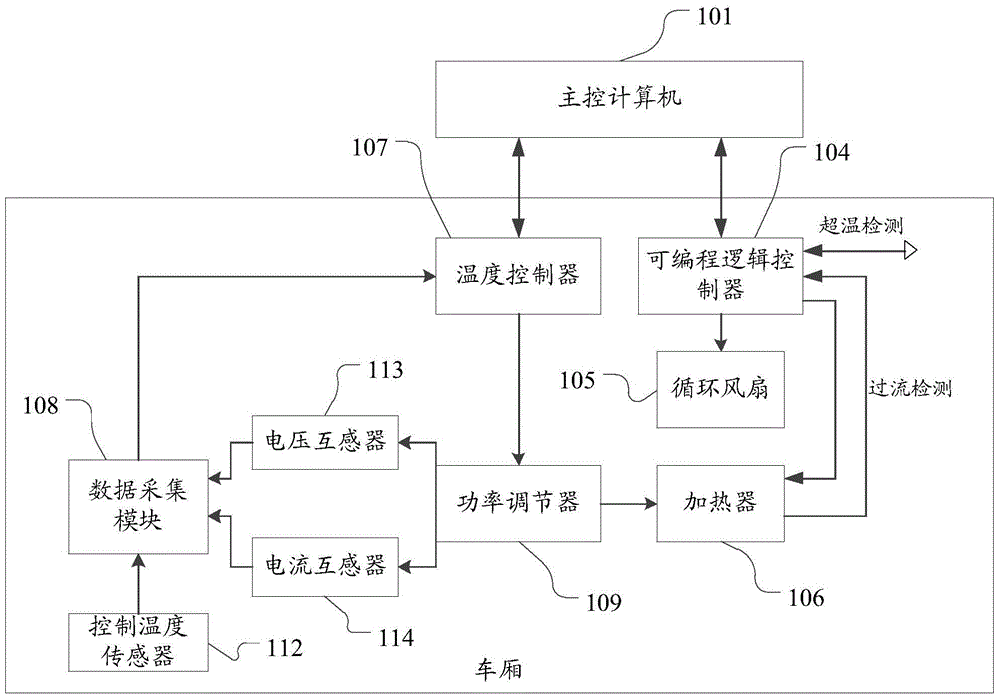

[0024] In order to understand more clearly the specific implementation of the vehicle compartment heat transfer coefficient testing system of the present invention, the detailed description will be given below with reference to the accompanying drawings.

[0025] Such as figure 2 As shown, a test system for the heat transfer coefficient of a vehicle compartment includes a main control computer 101, a programmable logic controller 104, a circulation fan 105, a heater 106, a temperature controller 107, a data acquisition module 108, a power regulator 109, a data acquisition Instrument 110, temperature sensor 111, control temperature sensor 112;

[0026] The main control computer 101 adjusts the temperature of the walk-in high and low temperature damp heat test chamber 102 with the compartment to be tested 103 to a preset temperature, and opens the circulation fan 105 and Heater 106; Temperature controller 107 receives the signal of the temperature setting value that main contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com