Control system for water-coal-slurry heat-conducting oil boiler

A technology for a heat transfer oil boiler and a control system, applied in the field of boiler control, can solve problems such as the inability to meet the high requirements of boiler reliability, and achieve the effects of stable heating, sensitive adjustment, and high temperature adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

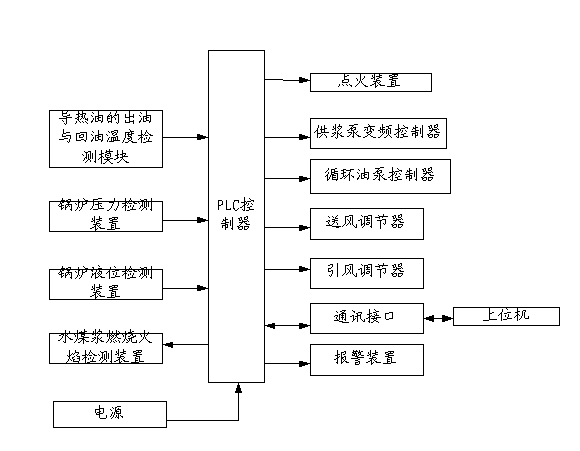

[0019] see figure 1 As shown, the figure shows the structure of a coal-water slurry heat transfer oil boiler control system provided by the embodiment of the present invention. For ease of description, only parts related to the embodiments of the present invention are shown.

[0020] see figure 1 , a coal-water slurry heat-conducting oil boiler control system, including a PLC controller with a built-in control program, the signal acquisition input end of the PLC controller is connected with an oil-out and oil-return temperature detection module of the heat-conducting oil, and a boiler pressure detection device , a boiler liquid level detection device and a coal-water slurry combustion flame detection device; the control output end of the PLC controller is connected to the indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com