Integrated temperature and pressure reduction device

A temperature reduction and pressure reduction, integrated technology, applied in the valve device, the valve device for absorbing fluid energy, the control of superheat temperature, etc., can solve the problem of small contact area, etc. The effect of reducing the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

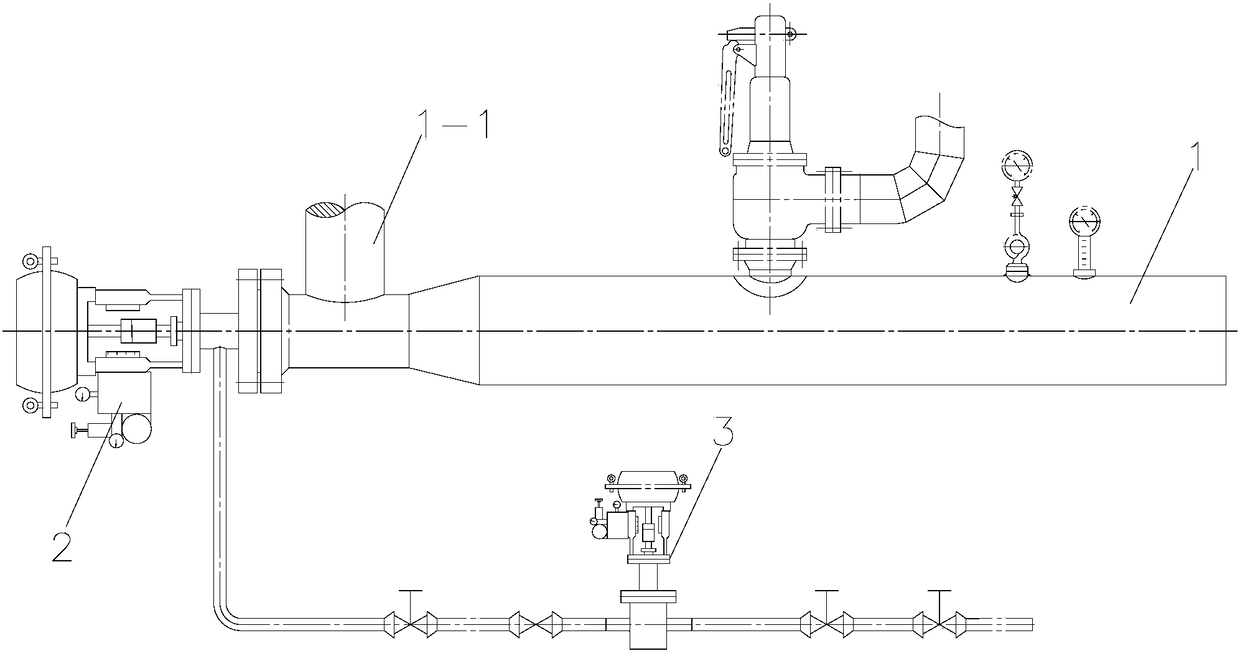

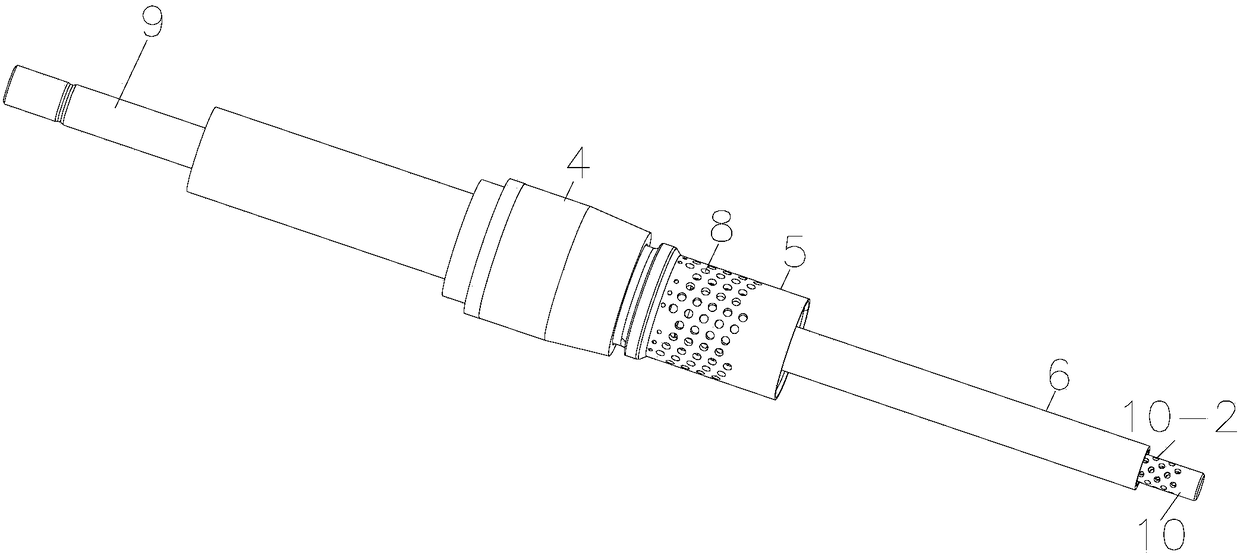

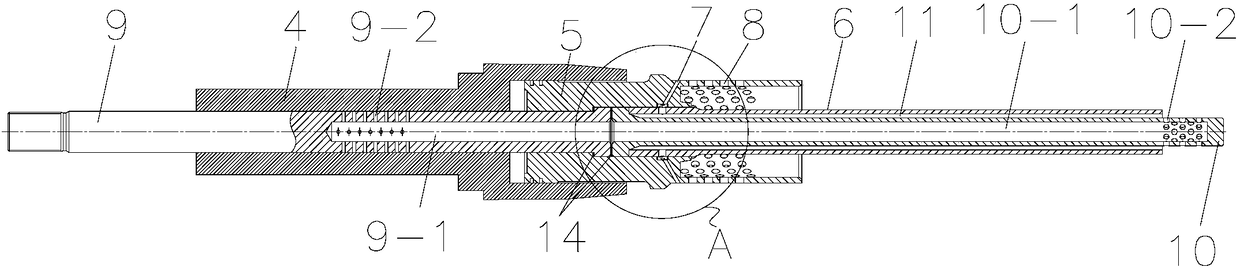

[0026] Such as figure 1 , 2 , 6, 7, 8 and 9, an integrated temperature and pressure reduction device, including a secondary steam pipeline 1 and a temperature and pressure reduction mechanism arranged in the secondary steam pipeline 1, the temperature and pressure reduction mechanism It includes an upper bonnet 4 and a valve core 5, on which several pressure-reducing holes are opened, and one end of the valve core 5 is inserted with a valve stem 9, and the valve stem 9 is close to one end of the valve core 5 A water delivery channel 9-1 is opened, and the outer peripheral surface of the valve stem 9 is provided with a number of water inlet holes 9-2 communicating with the water delivery channel 9-1, and the other end of the valve core 5 is inserted with a cooling water Pipe 10, the end of the desuperheating water pipe 10 close to the valve stem 9 is provided with a water outlet 10-1, the water outlet 10-1 communicates with the water delivery channel 9-1, and the desuperheatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com