Infrared heating graphite purifying furnace

A graphite purification furnace and infrared heating technology, applied in the direction of inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of reduced graphite purification effect, influence of graphite purification quality, inaccurate temperature control, etc., to achieve novel structure and simple production , The effect of high temperature adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

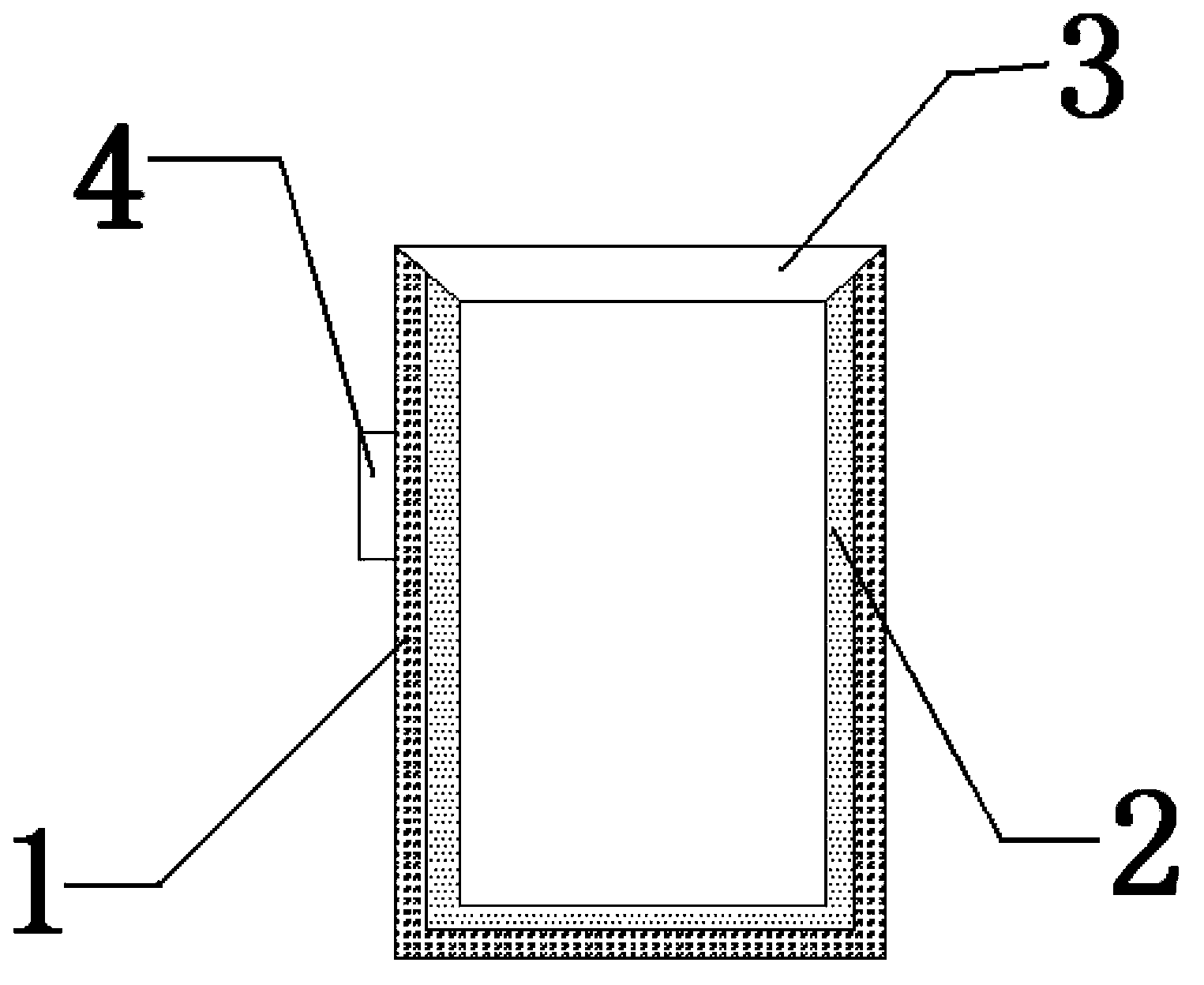

[0010] A kind of infrared heating graphite purification furnace as shown in the figure comprises a casing 1 and a top cover 3, a temperature regulator 4 is arranged on the outer wall of the casing 1; an infrared heating temperature control layer 2 is arranged on the inner wall of the casing 1, and the infrared heating The temperature control layer 2 is controlled by a temperature regulator 4; the shell 1 and the top cover 3 are flexibly connected.

[0011] The top cover 3 is snap-connected with the shell 1 .

[0012] The working process of this example: when using this purification furnace for graphite purification, pour the raw materials into the furnace body, make the raw materials contact with the infrared heating temperature control layer 2, cover the top cover 3, and then adjust the infrared temperature through the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com